Have you always wanted to travel through time like Marty McFly and Doc Brown in ‘Back to the Future’? Well, Great Scott! Now you can with this amazing 3D printed Delorean clock.

Originally released in 1985, the critically acclaimed film Back to the Future has proven itself to be timeless, which is a bit ironic considering the plot is about a teenager and mad scientist traveling through time. The instant classic quickly transformed into a gigantic franchise, spawning two sequels, several video games, a theme park ride, and even acting as the inspiration behind the main characters featured in the animated hit-series Rick & Morty.

Of all the many memorable scenes in Back to the Future, few are as iconic as those featuring the time-traveling Delorean, which is a sleek and futuristic car that is still famously recognized as “the car from that movie!” In the movie, Marty McFly and Doc Brown use the car as their personal time machine, dialing in the settings on the zany clock-like contraption that is mounted on the center console.

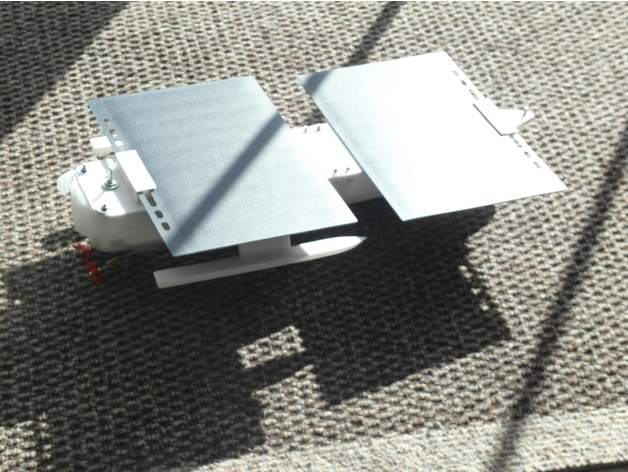

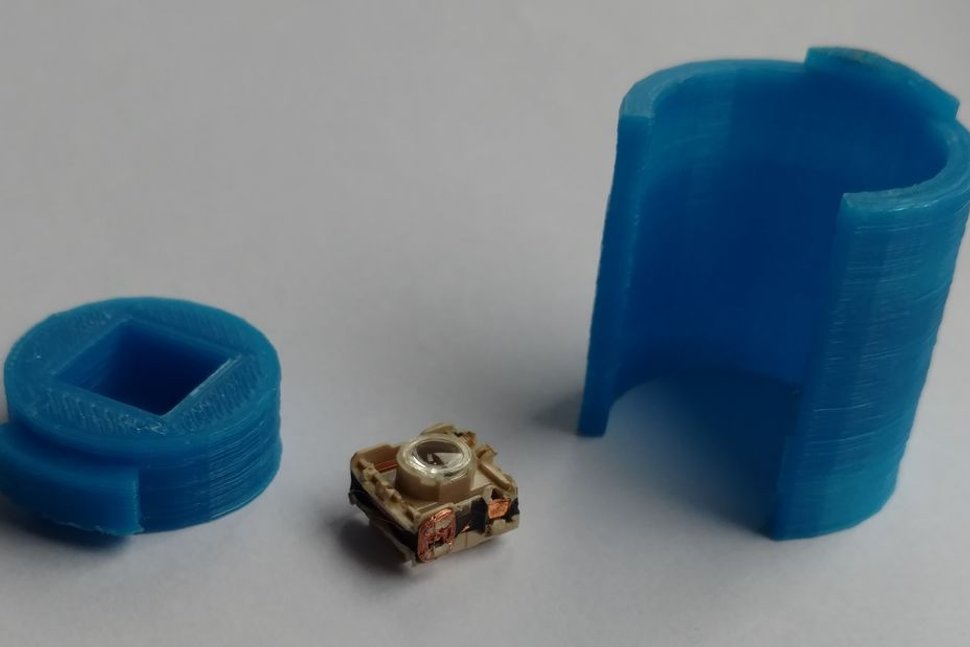

Now, fans of Back to the Future can 3D print their own time circuit device by following along with a project by Thingiverse user Premium95. The maker and engineer has created a 3D printable Delorean clock, taking the device from the film and turning it into a functional clock that shows you the time and date of the past, present and future.

This project requires a fair bit of soldering and post-processing, but hey, nobody said being a time traveller was easy work. If you’re up for the challenge, keep on reading to learn more about this awesome Weekend Project.

3D Printed Delorean Clock: What You Need & How to Build it

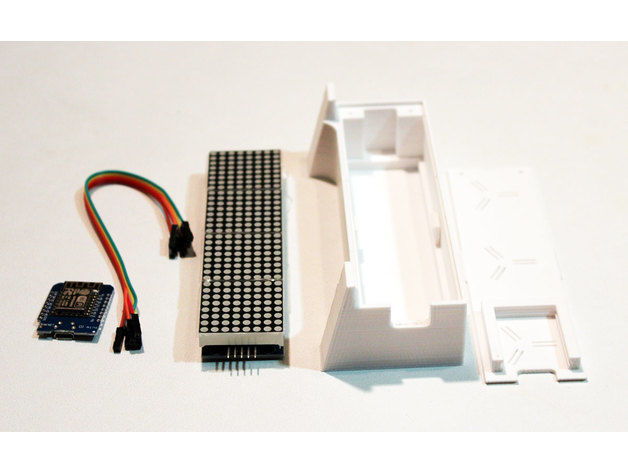

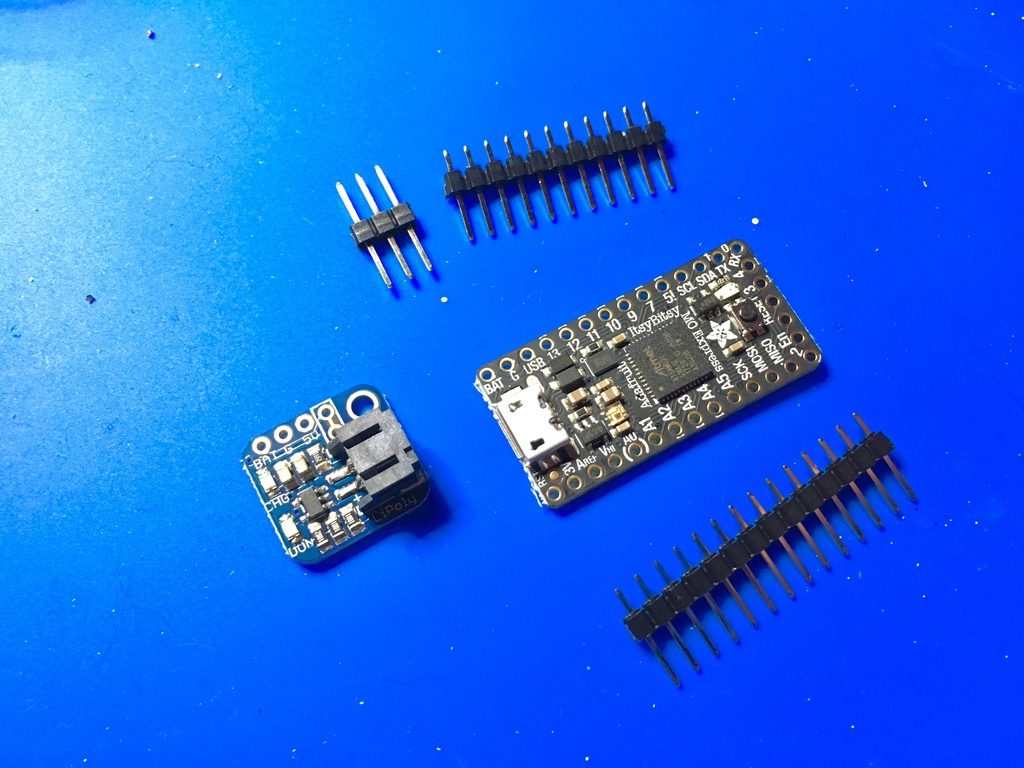

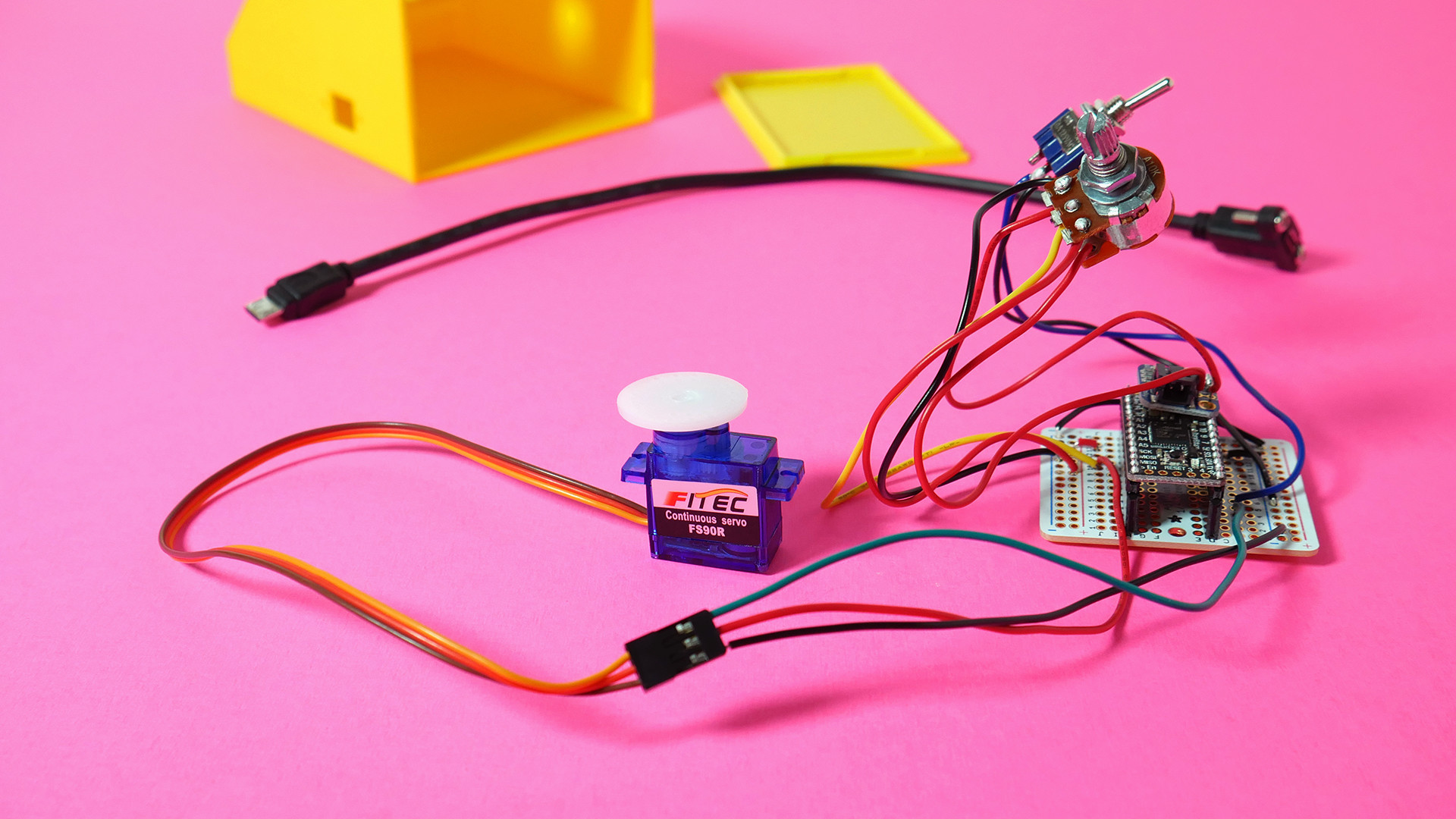

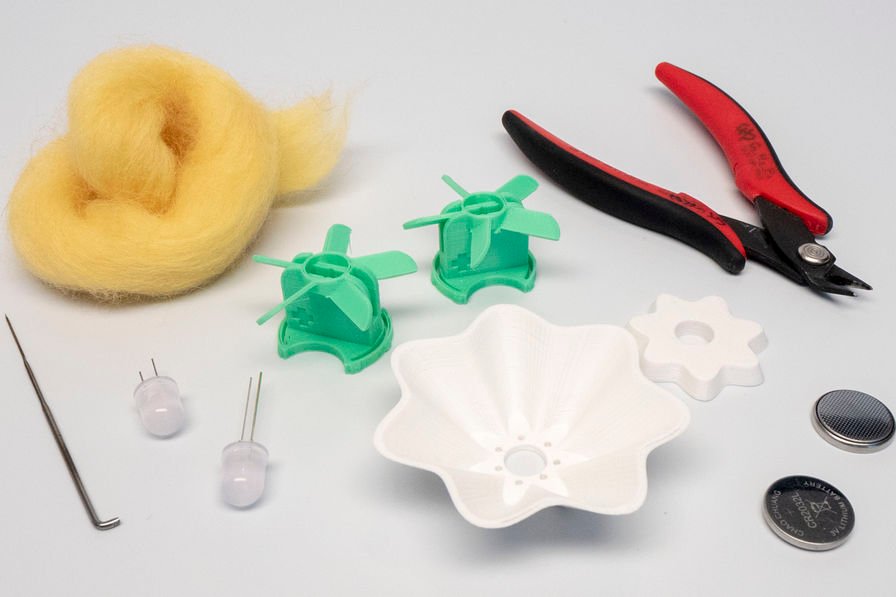

While the case of the Delorean Clock is 3D printed, you’ll still need a handful of electronic components and parts to complete the job. Here’s the checklist of what you need, all of which is available through Banggood:

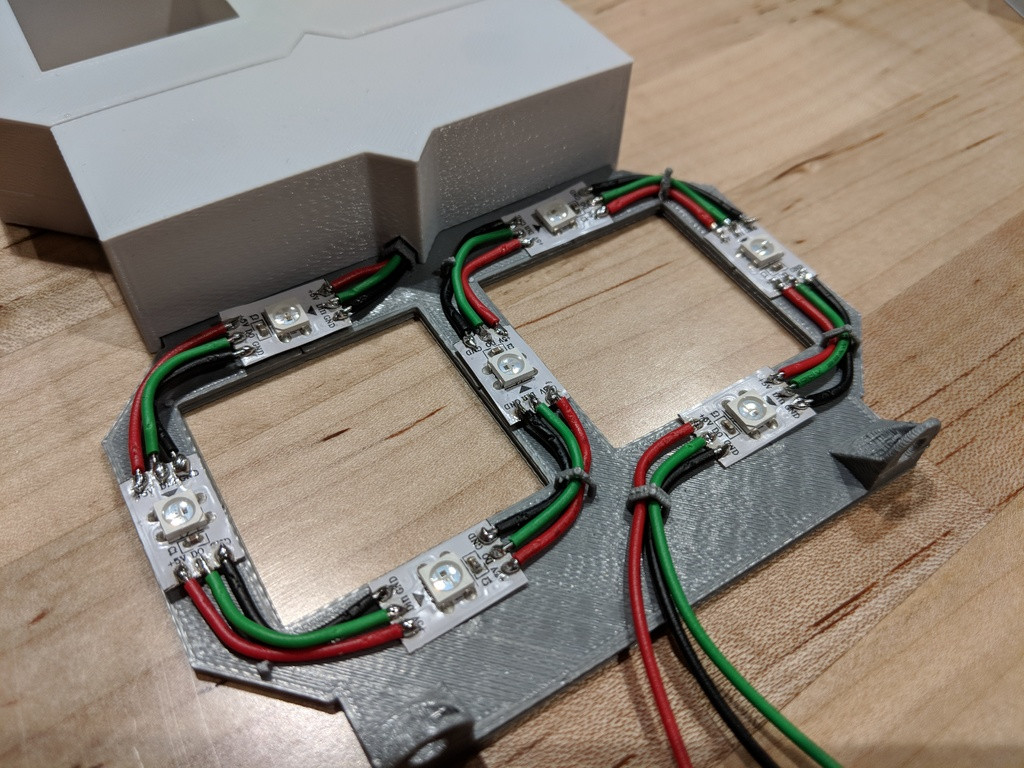

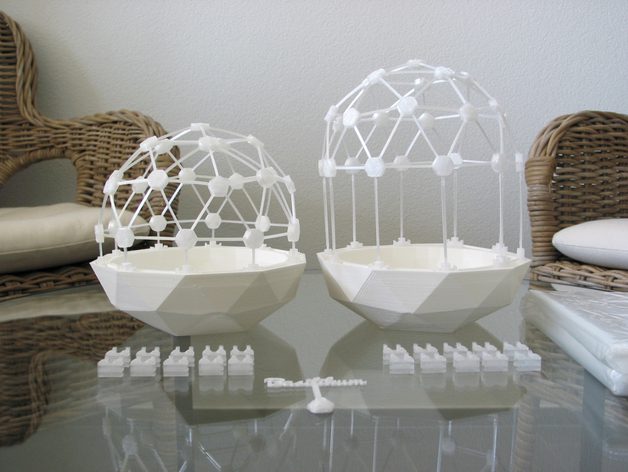

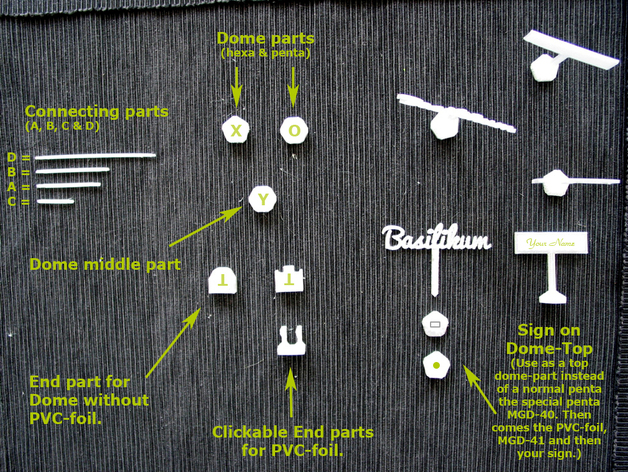

The Thingiverse user also shares a download link to the code that allows the Delorean to function. The labels that are attached to the clock are included in the collection of Thingiverse files. According to Premium95, the six 3D printable files should have 20 percent infill, no supports needed.

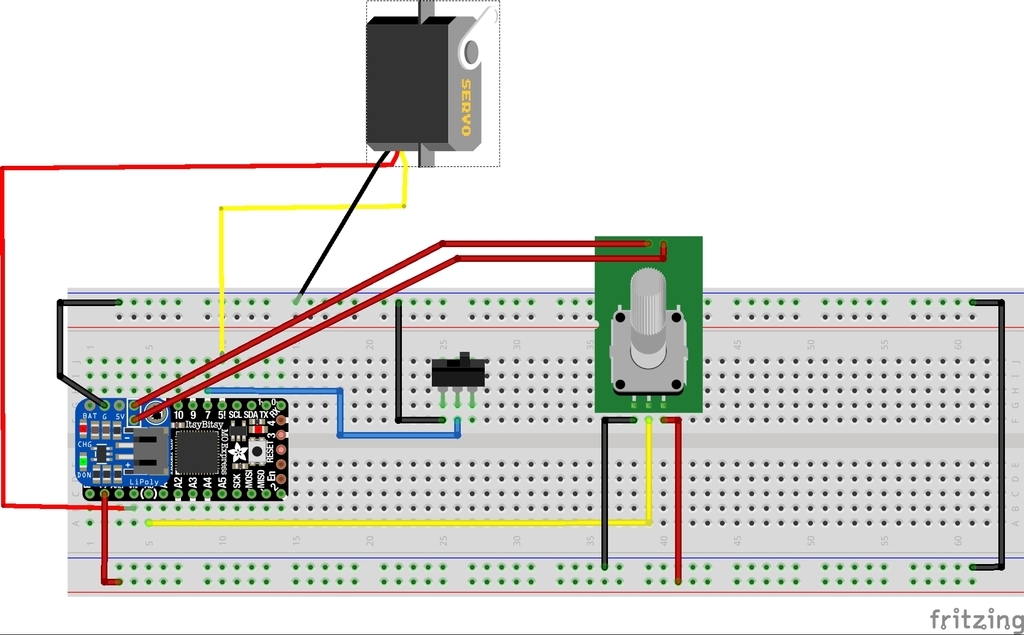

The engineer also shares the circuit digram for the entire clock, showing where soldering connections needs to be made.

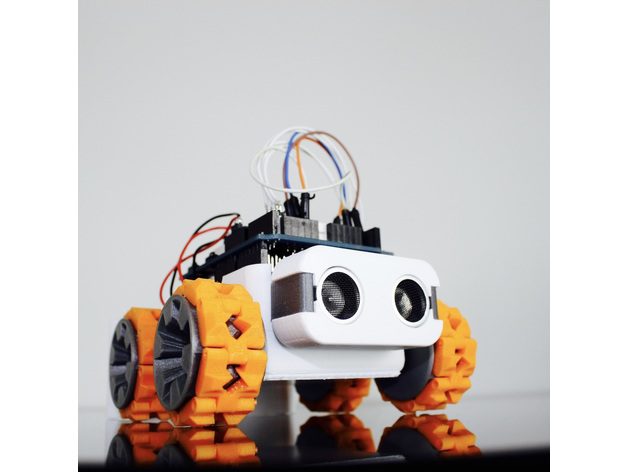

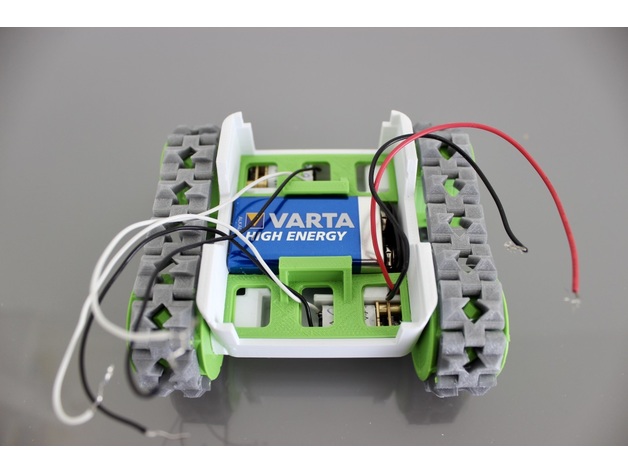

However, other than that, assembly instructions are sparse. Judging from the photos, the 3D printed parts seem to be post-processed with sandpaper and black paint.

The soldering process seems a bit complex for unexperienced makers, but this project can be approached as a challenging way to learn. Of course, if you have any questions about the project, you can head over to the Thingiverse page and drop a comment for the designer.

Website: LINK