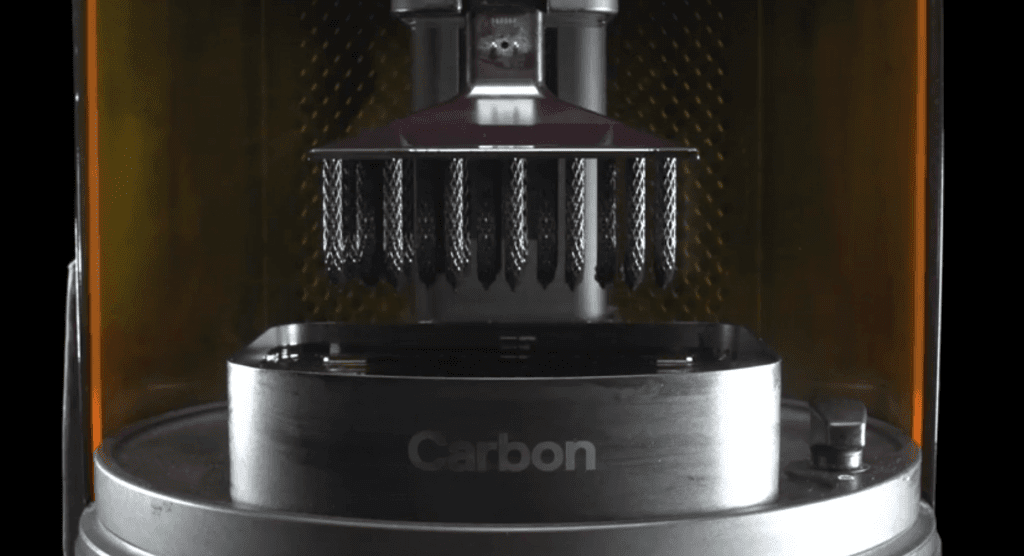

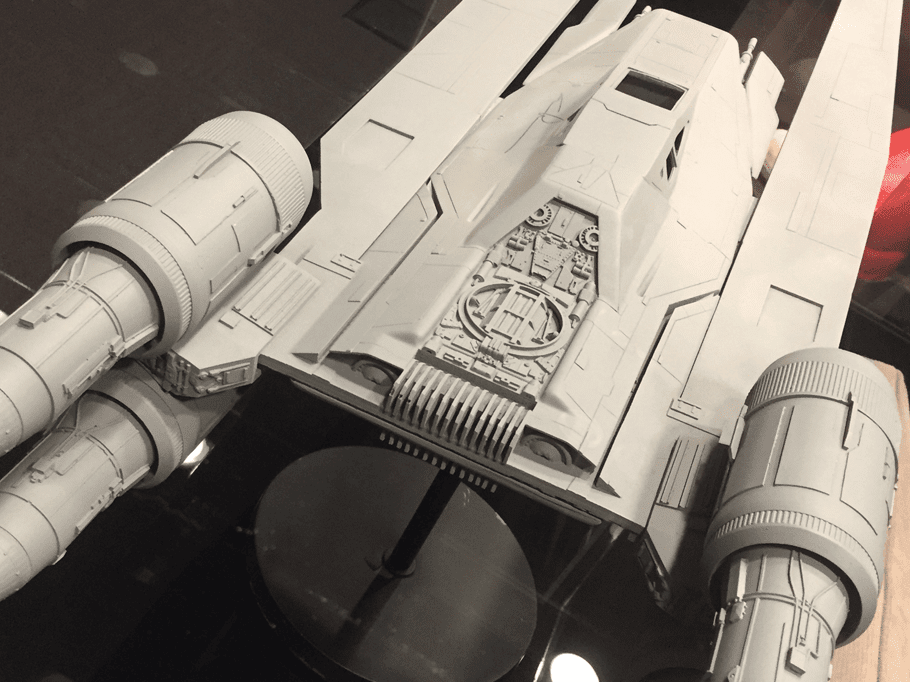

Previewing its new machine amid the crowded halls of CES, Nexa3D will demonstrate its debut ultra-fast stereolithography 3D printer. Interested parties can check out NXV in the flesh, with the company saying it will provide non-stop demos of the machine in action.

Nexa3D, the company that develops stereolithography professional-grade 3D printers, will be putting on a live demonstration at the Consumer Electronics Show (CES) in Las Vegas between January 9 to 12, 2018. As part of the showcase, Nexa3D is demonstrating its first professional 3D printer – the NXV.

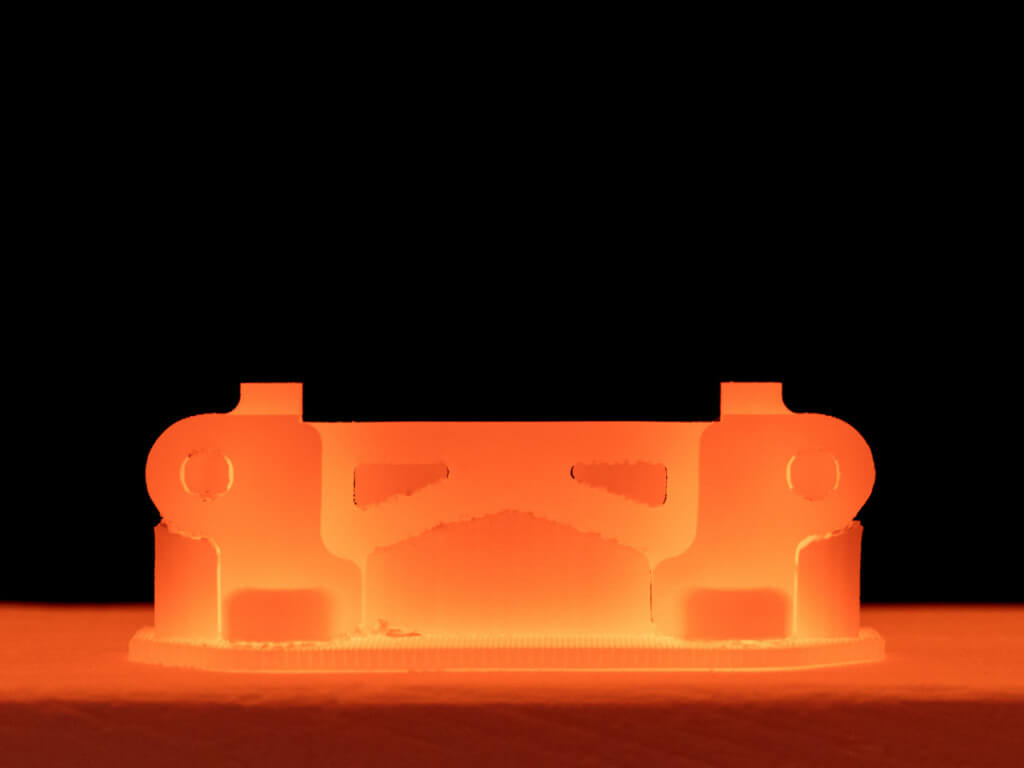

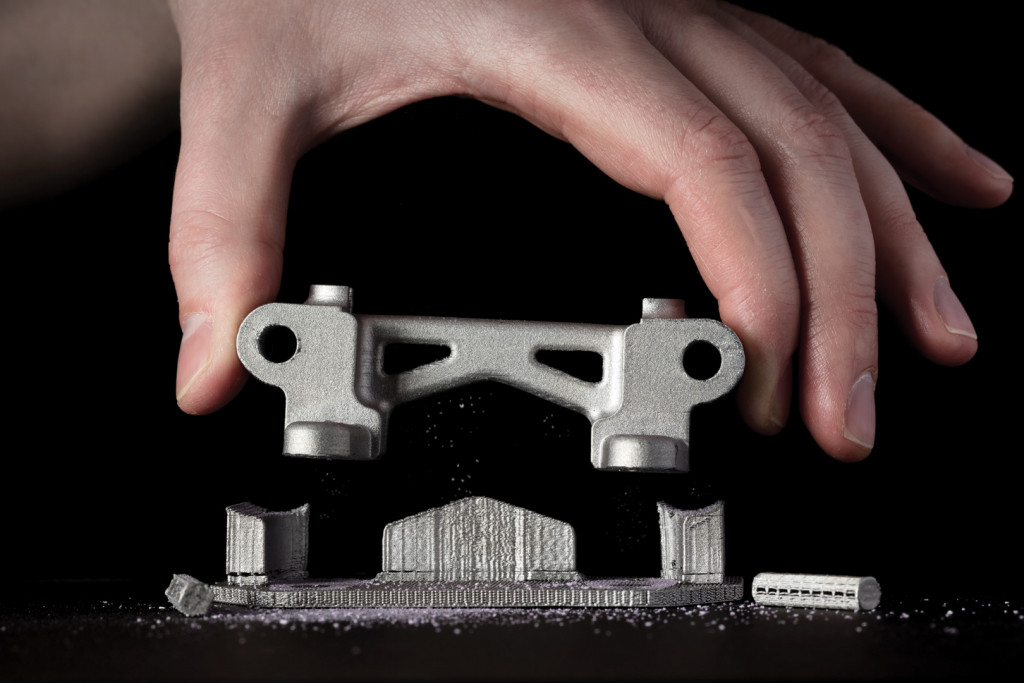

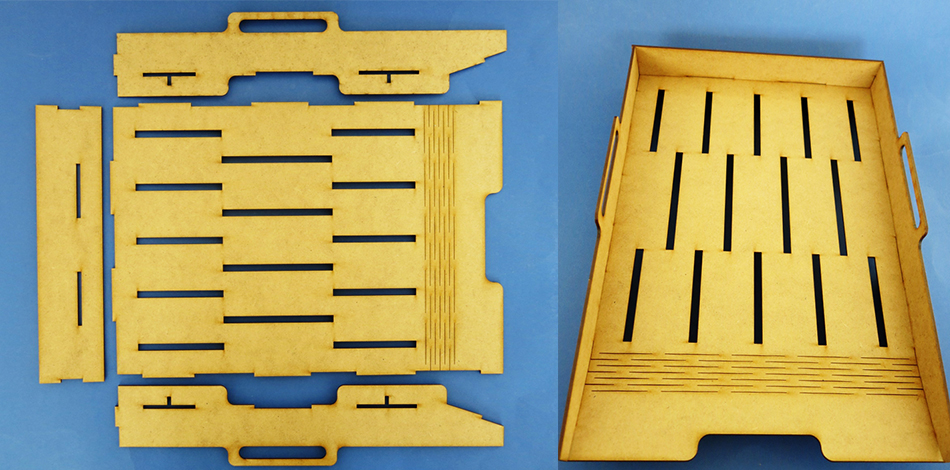

The company says that it is one of the largest and fastest, but also most accurate 3D printers in its category of professional desktop printers. It’s recommended for printing production tools as well as end-use parts and creating functional prototypes.

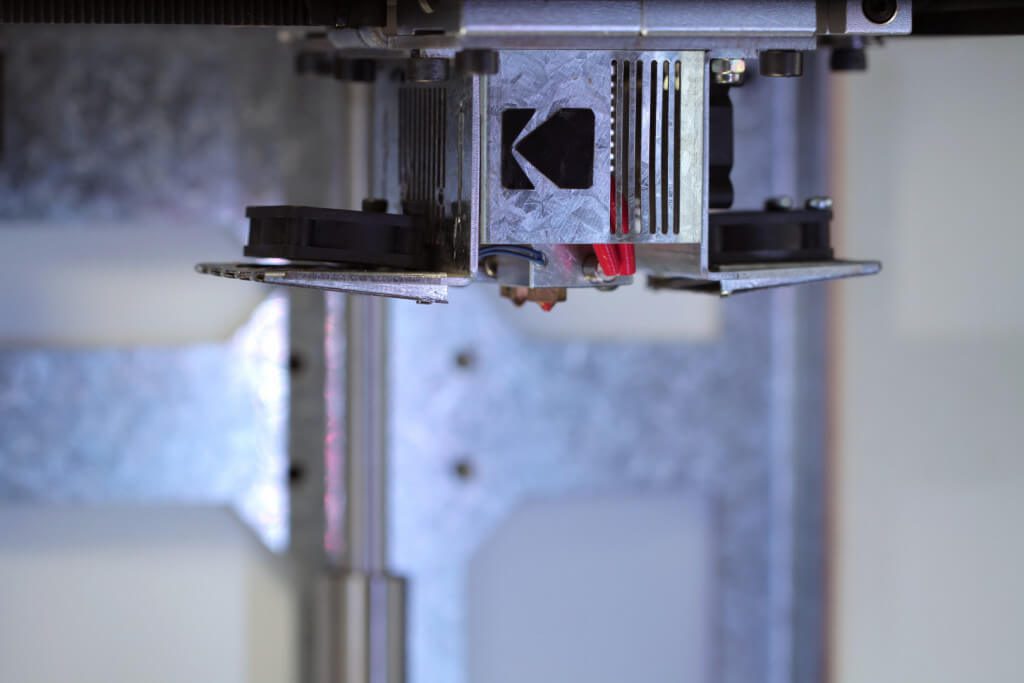

With a price tag of $19,950 one would expect some sophisticated tech under the hood. In a release, Nexa3D says the printer makes use of cognitive software and various sensors to help optimize part performance. The technology of the NXV is based on deep machine learning algorithms that can slice, optimize and compile more complex geometries whilst keeping the speed and resolution the same.

For added control, the 3D printer can run using both on-board and cloud controls for in-situ and remote operations of a single or multiple printers.

Nexa3D Starting 2018 on a High

Avi Reichental, Co-Founder and executive chairman of Nexa3D, explains “3D printing is an unstoppable force of change in every industry and within it, high-speed 3D printing is the next frontier in additive manufacturing and one that is highly valued by end-users, strategic partners, resellers and investors alike.”

“After several years of bootstrapping through the early stages of proving and nailing our game-changing technology, we are gratified to be here at CES 2018 with some of our early access marquee users and resellers who are partnering with us to validate the scaling of our first product,” he adds.

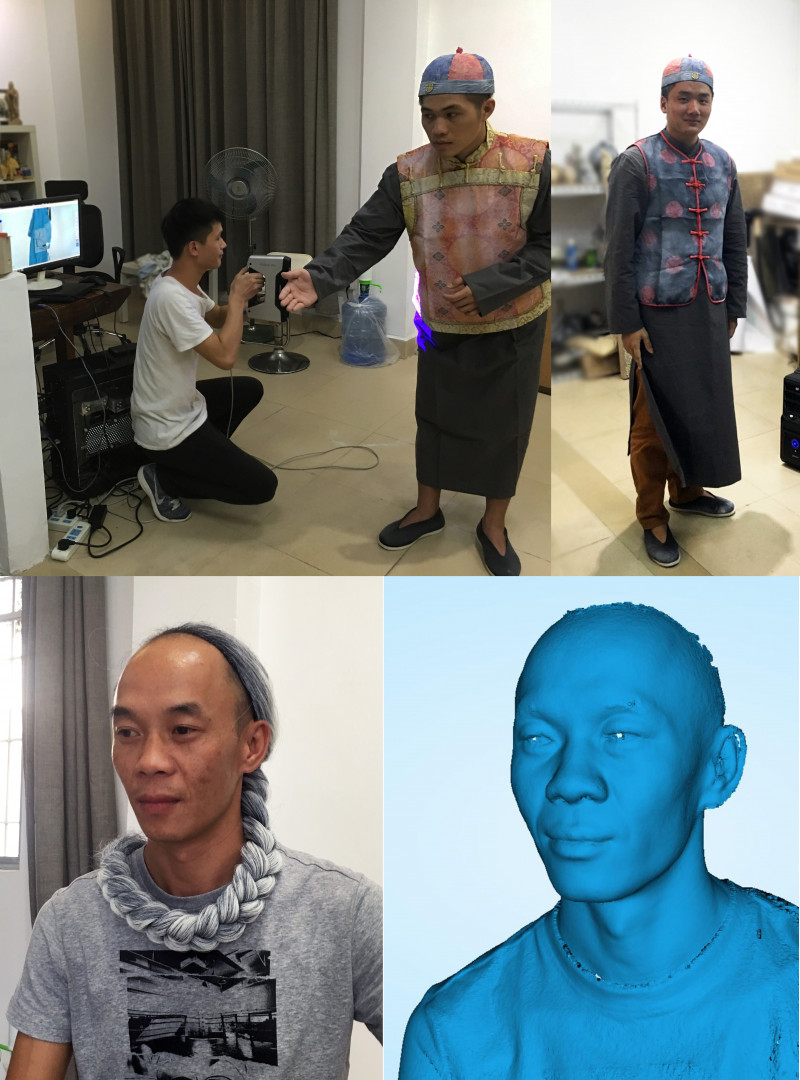

Just before the start of the CES, Nexa3D announced a partnership with BEGO, the digital and traditional dental materials and 3D printer provider, and XYZprinting, a desktop 3D printer brand. Together, the companies hope to transform digital dentistry. As part of the deal, BEGO will now be exclusively selling a special purpose high-speed Nexa3D dental printer that is being manufactured by XYZprinting. Nexa3D is exclusively developing the necessary technology and products.

In addition, Nexa3D announced another funding round with investor XYZprinting and crowdfunding from OurCrowd. This brings the company’s total funds to $10 million to date.

For more information and to check out the new NXV, you can find Nexa3D at the Techniplas booth #9100 at the Las Vegas Convention Center.

Source: Nexa3D

Website: LINK