Whether it’s the legendary Kodachrome film or high-tech printing machines, Kodak has always been at the forefront of science, art, and industry. To celebrate its 130th anniversary, Kodak will be presenting the new Super 8 and its first Portrait 3D Printer at the Consumer Electronics Show this January.

But if you just go to the 3D printing area at CES, you’d miss the highlight: Kodak’s Portrait 3D printer. You can find it at Kodak’s vast 50 x 50 ft booth at CES South Hall 1, Booth 20612. If you just come visit for a day and want to explore the 3D printing sector, make sure you don’t miss this important opportunity to see the Kodak system in action.

Kodak’s 3D printer has been built for classrooms, the office, or industrial environments. At a print volume of 200x200x250 mm it offers the right size for a variety of projects, whilst still fitting onto a desk. In addition, the device can be easily moved by one or two people.

The system combines the fully enclosed, compact dual-extrusion 3D printer as well as low-moisture filaments.

As a dual-extrusion printer, it offers a special function whereby users fill both extruders. Once one of them runs out of material, the second one jumps into action. That means users get to use up their partially-consumed filament spools without having to worry that they may run out of material. This saves money and time when creating larger, denser print objects.

Of course, you can use the dual-extrusion printer for regular dual-color 3D printing or soluble supports. To ensure that no color contamination occurs, the device also includes a nozzle-wiping mechanism.

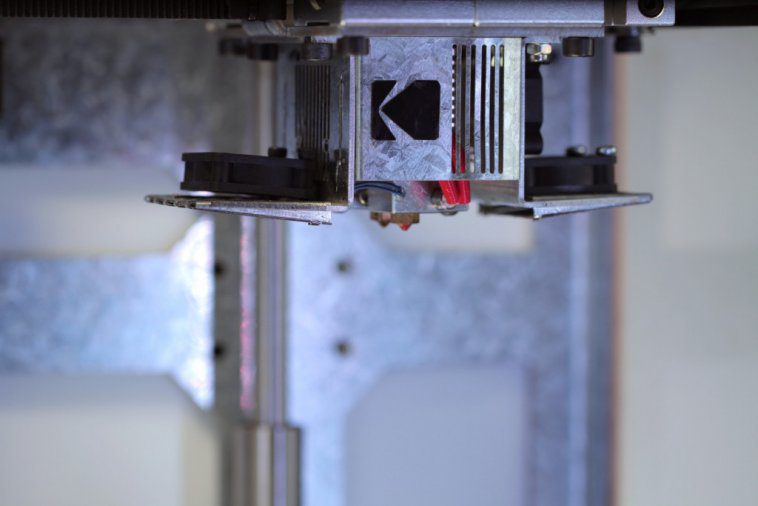

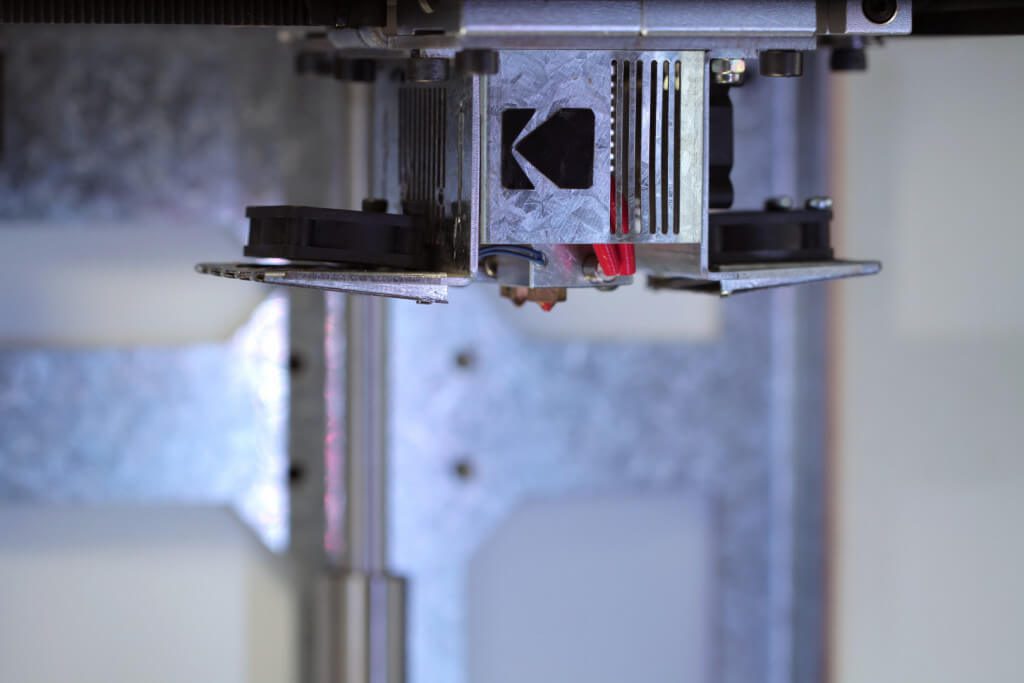

Built with reliability in mind, the 3D printer features steel sheets combined with thick guide rods and industrial bearing blocks that allow for the printer carriage to move more precisely. The electrical components of the device are easily accessible for maintenance but hidden out of sight.

The extrusion system of the Kodak 3D printer (Image: Kodak)

A 3D Printing Ecosystem for an Enhanced Printing Process

Together with the 3D printer, Kodak has developed a 3D Printing Ecosystem that includes 3D printing filament. That doesn’t mean one cannot use their own, third-party filaments, but the Kodak 3D Printing Filament offers several advantages that are worth exploring.

Firstly, the filaments are low moisture and supplied in airtight foil packaging. That’s an important aspect given that materials such as PVA and nylon tend to absorb air moisture more rapidly. Moist filaments can obscure the printing process.

They fit perfectly into the airtight protection cartridges to shield them from humidity. Once placed inside the cartridges, which connect to the extruders, the system remains shielded from humidity or dust. This offers an additional layer of longevity to the system by preserving filament quality.

Among the materials on offer, Kodak currently has PLA+, PLA Tough, ABS, HIPS, Flex 98, Nylon 6 and Nylon 12 in store. The filaments offer the highest roundness and diameter accuracy available in the market.

As a final touch, the Kodak 3D printing system comes with user-friendly software. It includes Wi-Fi, email and social network connectivity for easier file-sharing. For educational institutions, there is also the option of multi-user platforms with statistical data. Remote print monitoring and management may also come in handy when scheduling larger print projects that require longer runs.

During the time of CES, the 3D printer will be available at a discounted price. To find out, Kodak encourages you to visit the booth (booth number 20612, South Hall 1) and talk to one of their representatives. The device will begin shipping in March 2018.

Kodak 3D Printing Filament is low-moisture. (Image: Kodak)

(Source: Kodak)

Website: LINK