At the University of Canterbury, academics have developed original tech to produce heat exchangers that could have wide-ranging applications, from motorsports to laptop batteries.

A press release from the University of Canterbury, New Zealand, claims Professor Conan Fee and Dr Tim Huber have created high-performance heat exchangers that could be a “game changer” for design and efficiency.

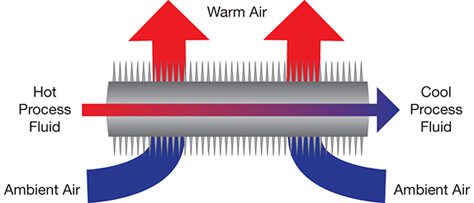

In brief, a heat exchanger is a device that effectively transfers heat between two (or more) materials, typically a solid and liquid, or multiple liquids. You can find them in things like air conditioners and car engines.

One practical benefit of such devices can be energy recovery (channeling waste heat to other areas where needed). There are numerous others — it is a complex technology with broad application, after all — but the Canterbury academics’ new spin appears to be more in line with small-scale electronics and heat dissipation.

Custom Cooling Thanks to 3D Printing

Using undisclosed 3D printing tech, the academic’s work posits radical new shapes that boast efficiency both in performance and footprint. Thanks to the oft-cited benefit of 3D printing being able to render complex geometries that traditional manufacturing would struggle with, these new heat exchangers can be in fitted in unusual and constrained spaces.

Producing critical components in such spaces and sizes could have a dramatic effect on future technology, with lighter racing cars and aircraft, plus smaller heat pumps for the home cited as possible examples.

Speaking of 3D printing’s role in the work, Fee said “The growth of 3D printing for new applications is exponential and it is stimulating a huge set of opportunities for new designs that were not previously possible. Our 3D-printed porous heat exchangers are an example of something that cannot be made by conventional technologies but is now possible, expanding our thinking and potentially growing innovation in New Zealand.”

The pair’s work has won research funds from the university’s Tech Jumpstart Competition. Fee and Huber will receive $20,000 dollars over six months to mature the technology for commercial release.

Source: Canterbury.ac.nz

Website: LINK