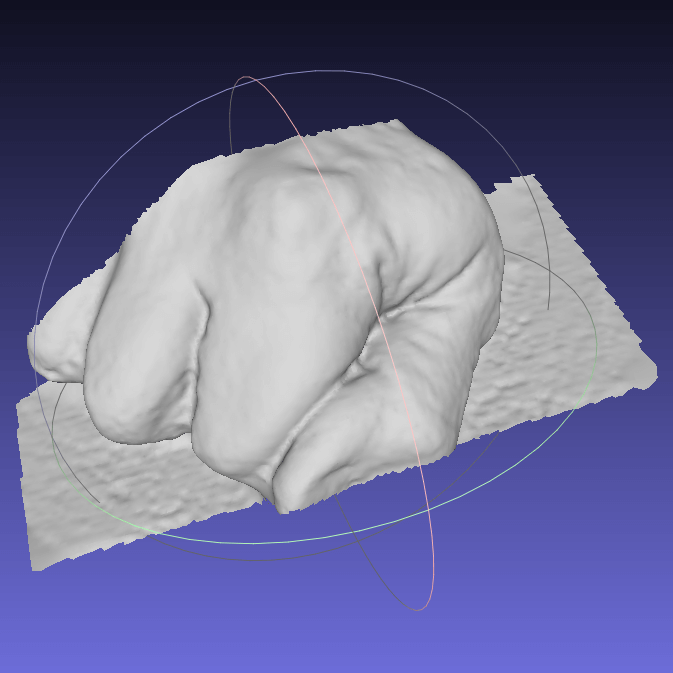

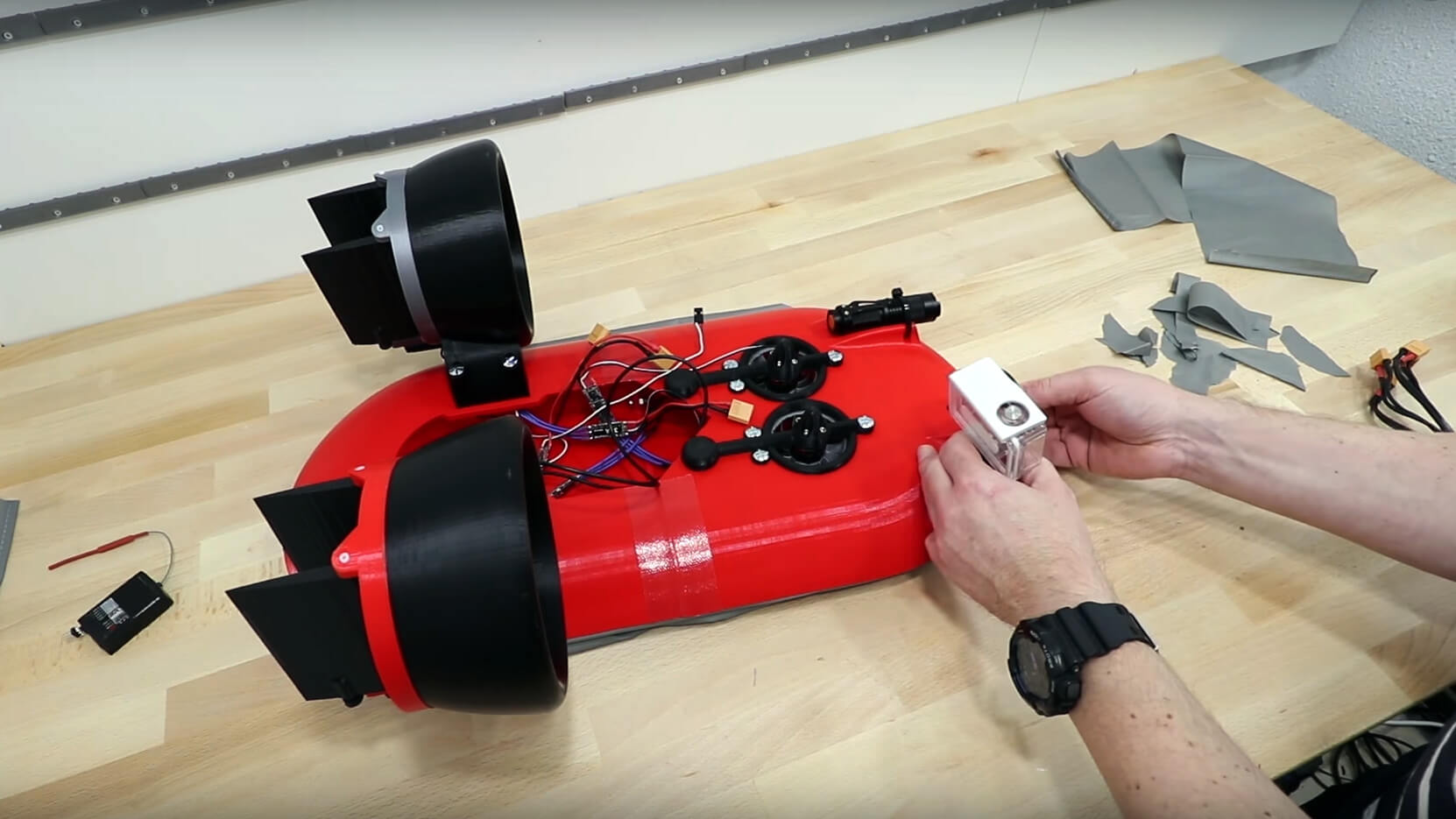

The arrangement takes four images at the same time to create a 3D model of the object.

A creator on Hackaday has developed a novel scanner which can instantly capture a 3D surface. Going by the name ‘Jolar’, the developer has been busy refining his 3D scanner project from Oxford Hackspace.

The scanner consists of four Raspberry Pi Zero cameras which can capture the desired object from different angles. The cameras are synchronized and images are uploaded to the cloud once ready.

The fitted projector projects a random pattern onto an object. However, for the projector to zoom more closely, Jolar fitted a lens from a pair of reading glasses.

In combination, the cameras and projector capture the four images which are then uploaded for processing to a laptop.

The 3D scanner also includes a Multi-View Stereo (MVS) algorithm that then turns the four images into a 3D model.

The MVS matches up features within each image in order for the distance to be triangulated. By projecting multiple features onto an object, a more accurate 3D mesh can be returned.

Jolar uses VisualSFM, an application for 3D reconstruction that uses motion, to do the image processing. The resulting files are then opened in MeshLab or CAD.

Scanning with Raspberries

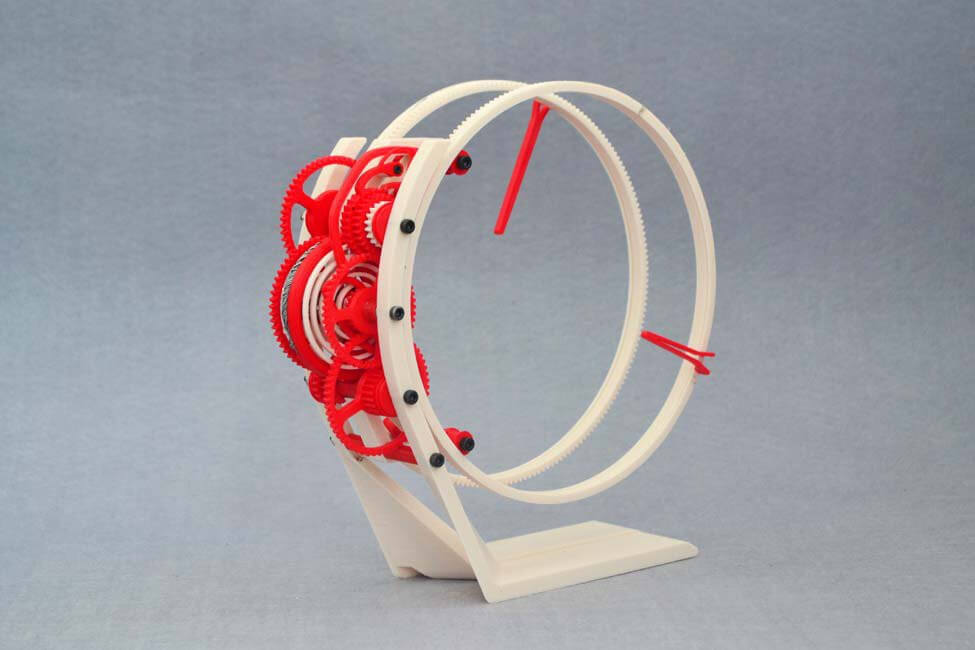

It’s not the first time Raspberry Pi cameras have been used in connection with 3D printing.

Indeed, user ‘Richard’ has created a Raspberry Pi 3D Scanner which consists of 100 of the Pi cameras. It allows him to take full body shots of people or animals (even the ones who don’t like to sit still).

A model from 100 photos can then be created using Autodesk Recap 360 or Agisoft Photoscan. In turn, these models are then used to develop the 3D print.

100 Raspberry Pies scanner. (Image: Pi3DScan)

Source: Hackaday & Pi3DScan

Website: LINK