Morehshin Allahyari is an Iranian artist and activist. For her latest exhibition, she is using ancient illustrations of Middle Eastern dark goddesses to create sculptures using 3D modeling, scanning, and printing. Her aim is to fight against “digital colonialism” with the display called She Who Sees the Unknown.

Digital colonialism, artist and activist Morehshin Allahyari explains, is when a company goes to a Middle Eastern cultural site and begins a reconstruction project which then isn’t made public. She adds that corporations are even using traditional mythologies and cultural artefacts to make a profit.

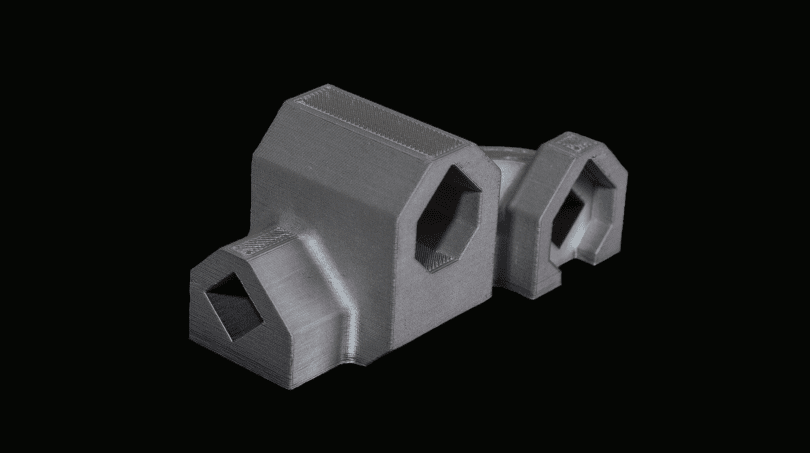

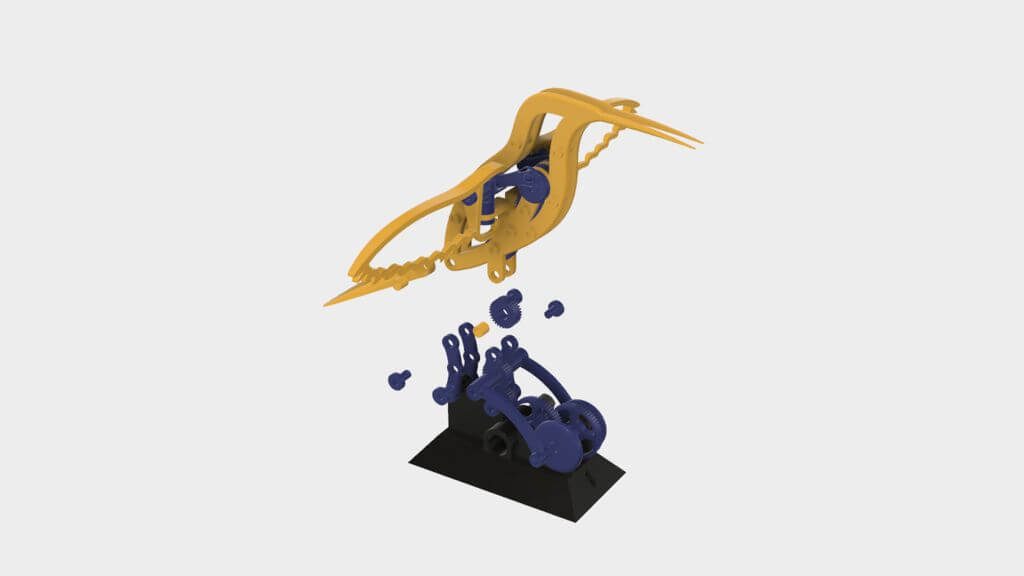

However, Allahyari is countering this by using 3D modeling, scanning, and printing to redistribute forgotten cultural artefacts. By using modern technologies to create 12 sculptures, she is archiving dark female figures worth remembering.

Her source material is ancient illustrations of Middle Eastern dark goddesses. The interesting results are her way of reclaiming ownership of traditional mythologies.

The work, called She Who Sees The Unknown, is now on display at The Armory in New York City. The display explores the “forgotten histories and narratives” of female figures in North Africa and the Middle East.

“It’s a meaningful archive that’s focused on these kinds of dark female figures in the Middle East. We don’t have that archive at all,” Allahyari explains.

a

She Who Sees the Unknown Made Using Ancient Sources and Modern Technology

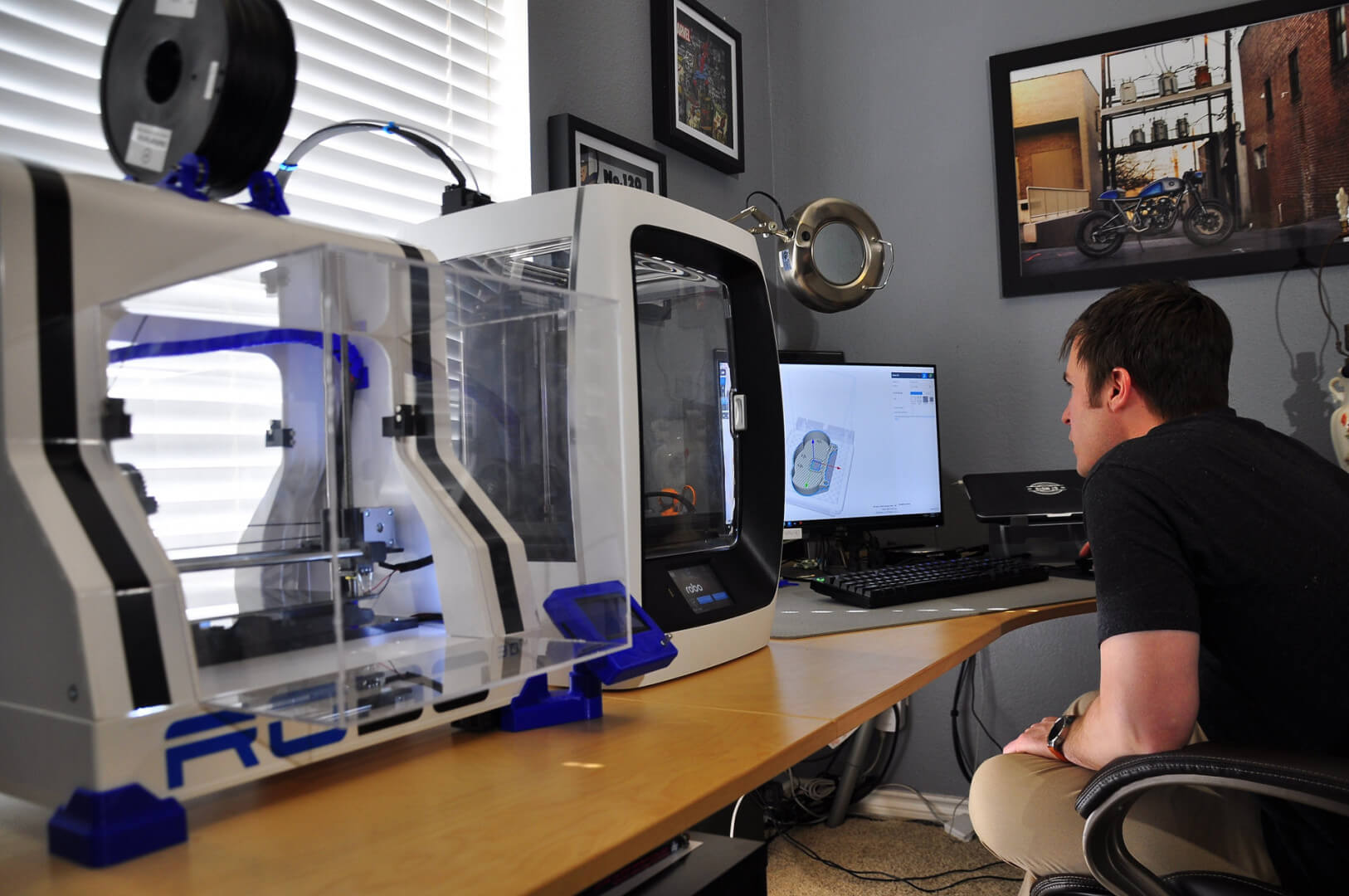

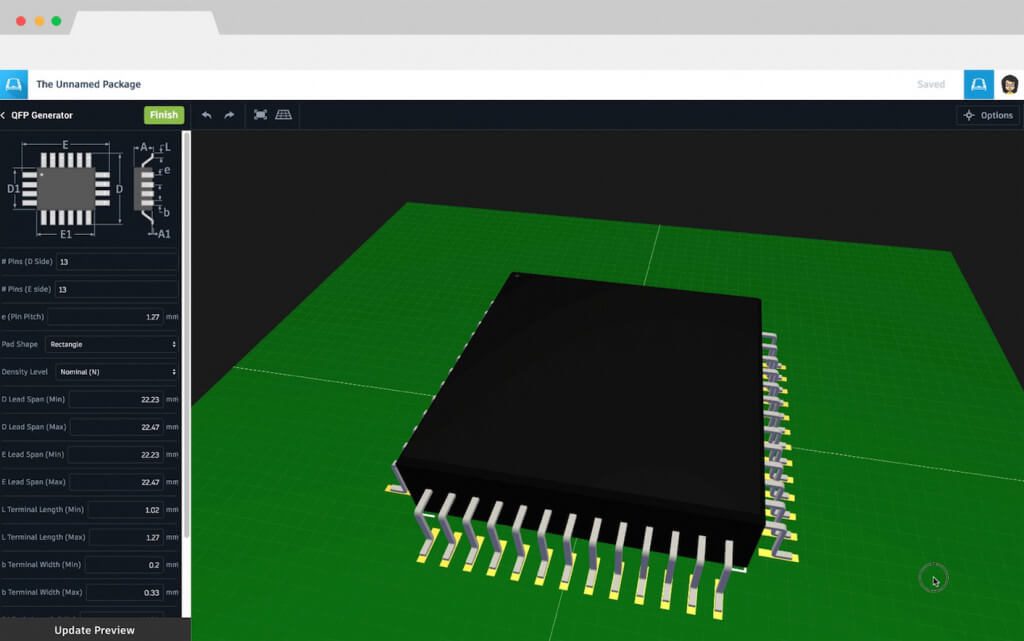

Allahyari explains that she is not a sculptor and that she wouldn’t know where to begin. But 3D modeling and printing is something which she knows how to do well.

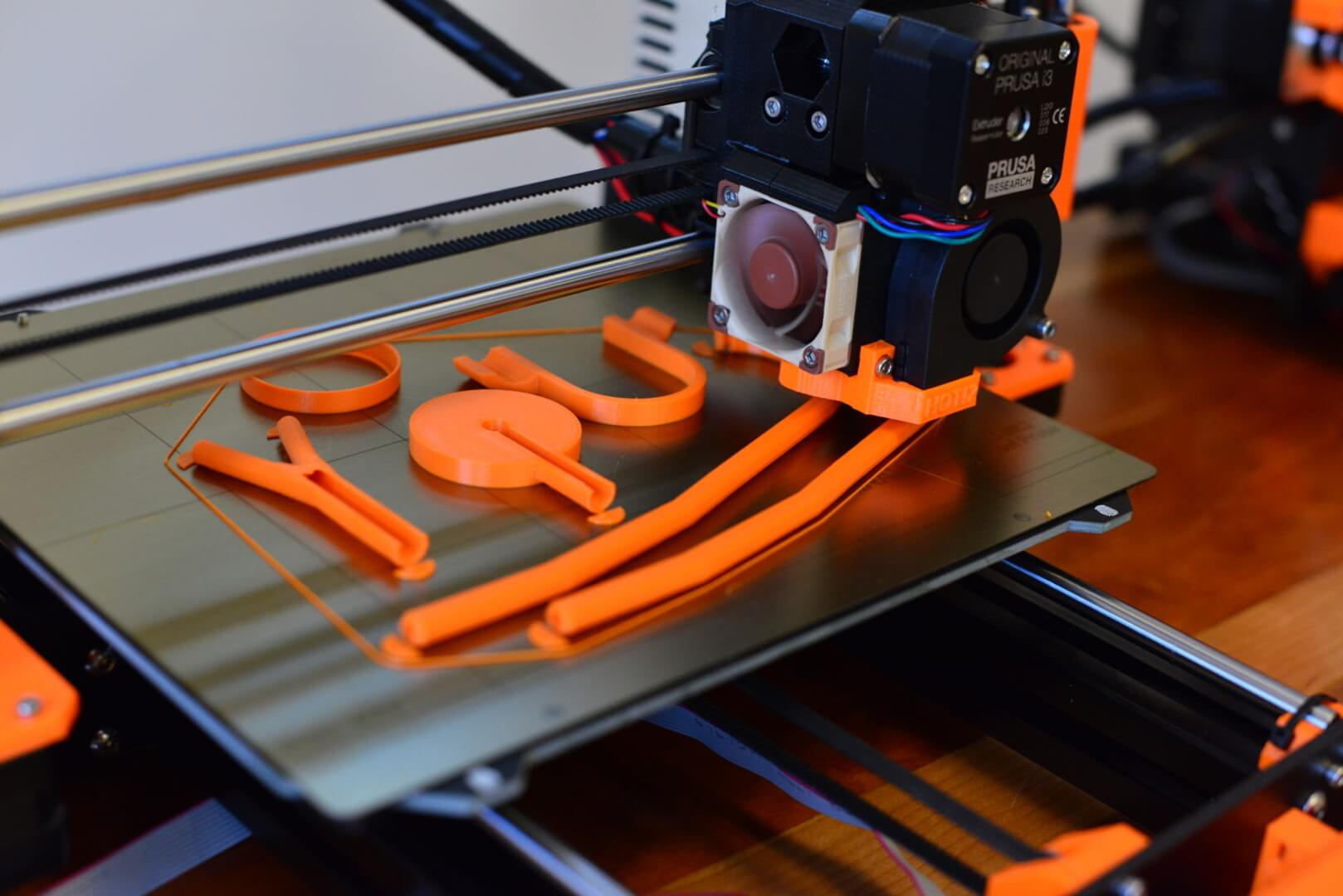

“The first time that I saw an object getting 3D printed, I was really fascinated by this idea of seeing a digital file, a digital model from a platform becoming a physical object. It blew my mind actually watching that process,” Allahyari said.

To create She Who Sees the Unknown, Allahyari began by researching Middle Eastern ancient texts. She wanted to make sure her prints were as accurate as possible.

Next, she created a scan of each sculpture and 3D printed it. To print, Allahyari used resin and the Stratasys J750 printer at New York University’s LaGuardia Studio. Each sculpture takes between fifteen and twenty-five hours to print. Allahyari then sands down and paints the resulting prints.

Finally, to ensure the information is clear and available to the public, Allahyari has included a video essay or storytelling component with each of the sculptures. The stories link each goddess to a modern source of oppression.

As well as the sculpture, She Who Sees the Unknown will include Ha’m-Neshini or “intimate public performances”. These involve Allahyari sitting together with other activists, artists and even scientists from the Middle East.

“In this whole body of work, these figures and retelling their stories is the idea about what it means to embrace monstrosities and to take this power that these jinns have and use it against the powers that oppress,” Allahyari says.

Find out more about each of Allahyari’s figures and their meanings along with her own story on her website.

Source: The Verge

Website: LINK

![[DEAL] Sindoh 3DWOX DP201 3D Printer, $400 Off](https://www.blogdot.tv/wp-content/uploads/2018/03/deal-sindoh-3dwox-dp201-3d-printer-400-off.jpg)

![[DEAL] Creality CR-10 3D Printer, Over 28% Off](https://www.blogdot.tv/wp-content/uploads/2018/03/deal-creality-cr-10-3d-printer-over-28-off.jpg)