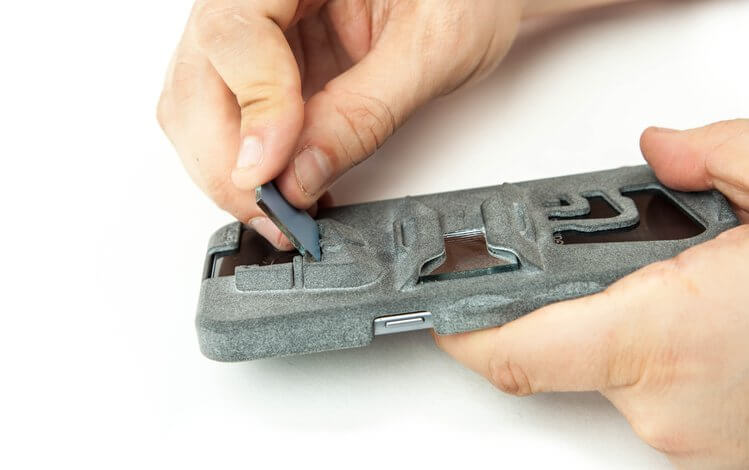

The construction company ICON is working together with the charity New Story to combat inadequate housing across the globe. Using ICON’s Vulcan 3D printer, the collaborative effort aims to 3D print 650-square-foot homes that are affordable and sustainable.

With 3D printing emerging throughout the construction industry, the technology is becoming a groundbreaking production tool for affordable and sustainable housing. The latest organization to adopt 3D printing into its humanitarian efforts is New Story. The charity’s mission is to place people without adequate housing into a proper shelter, taking them away from the throes of “survival mode”.

The non-profit organization is now working with ICON, an Austin, Texas-based construction tech company. ICON has unveiled the Vulcan 3D printer at SXSW Festival, a manufacturing solution that could eventually provide homeless or struggling families with a roof over their heads.

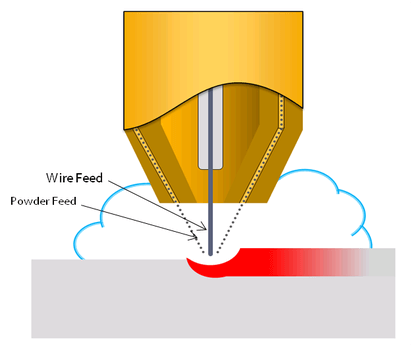

Together, ICON and New Story are 3D printing homes using a cement mixture. Each structure takes around 12 to 24 hours to produce. The 650-square-foot single story homes have a modern design.

The current plan is to build 100 homes in El Salvador next year. According to Alexandria Lafci, co-founder of New Story, the charity has also been 3D printing homes for communities in Haiti, El Salvador, and Bolivia.

However, before these homes are built, ICON is planning to trial the model by 3D printing an office in Austin. Within the office, the construction tech company plans to install air quality monitors and keep an eye on how the 3D printed structure looks and smells.

New Story and ICON Attempt to 3D Print Sustainable Homes for $4,000

New Story explains on its website that last year, the technology they needed to create homes quickly and cheaply wasn’t available yet. However, by working alongside ICON, they now have access to the impressive Vulcan 3D printer.

Currently, it costs $10,000 to 3D print a home with the Vulcan 3D printer. Eventually, ICON hopes to reduce this construction cost to just $4,000.

“There are a few other companies that have printed homes and structures. But they are printed in a warehouse, or they look like Yoda huts. For this venture to succeed, they have to be the best houses… I think if we were printing in plastic we would encounter some issues,” explains co-founder of ICON, Jason Ballard.

Since these structures need to be sturdy and hospitable, the companies aren’t taking any risks and will be refining the process right up until they take it over to El Salvador. If all goes according to plan, we may soon see the Vulcan 3D printing homes in the United States as well.

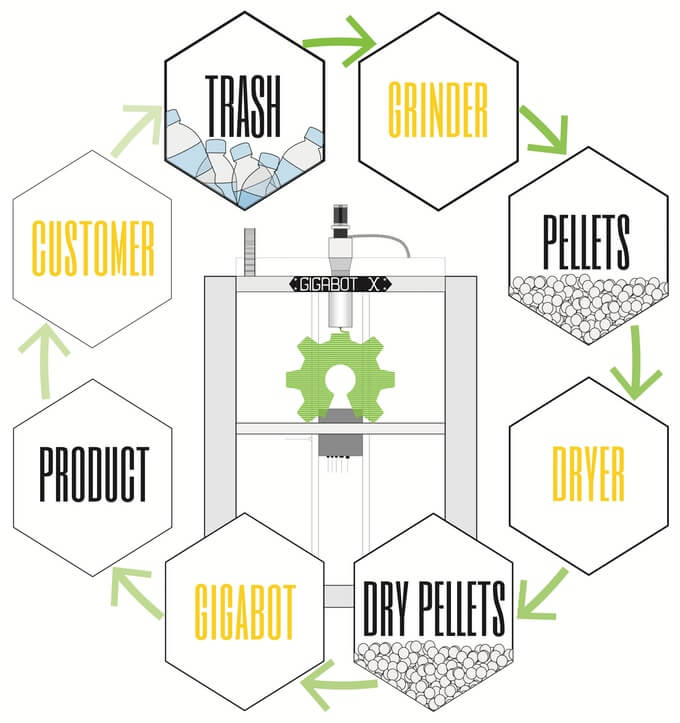

As we’ve seen in cases both inside and outside of the construction sector, 3D printing offers many benefits other than just being very quick. The technology also tends to reduce waste and manual labor costs.

After solving the vast housing and homelessness problems that plague the Earth, Ballard hopes to use 3D printing to help humans build homes in outer space. He explains: “One of the big challenges is how are we going to create habitats in space… You’re not going to open a two by four and open screws. It’s one of the more promising potential habitat technologies.”

In the meantime, if you’d like to join the effort to eliminate homelessness on Planet Earth, you can donate to the cause on the New Story website.

Source: The Verge

Website: LINK

![[DEAL] Sindoh 3DWOX DP201 3D Printer, $400 Off](https://www.blogdot.tv/wp-content/uploads/2018/03/deal-sindoh-3dwox-dp201-3d-printer-400-off.jpg)

![[DEAL] Creality CR-10 3D Printer, Over 28% Off](https://www.blogdot.tv/wp-content/uploads/2018/03/deal-creality-cr-10-3d-printer-over-28-off.jpg)