Kategorie: Science

-

BMW Mini Commemorates Royal Wedding with Unique Car Design

Reading Time: 3 minutesBMW has created a special-edition Mini to celebrate the royal wedding of Prince Harry and Megan Markle. Boasting a hand-made graphic print and 3D printed details, the car will be auctioned off for charity. What could be more British than a royal wedding? A one-of-a-kind Mini Cooper S with a bold graphic…

-

Experimental Ceramic Resin for the Form 2 Now Available

Reading Time: 2 minutesA new experimental Ceramic Resin is a now available for the Form 2 from Formlabs, making ceramic 3D printing the most affordable and accessible it has ever been for engineers and designers. Stereolithography specialists Formlabs have announced the availability of a special new material for their Form 2 desktop 3D printer. Their…

-

AUGGMED Trains Police and Aid Workers for Terror Related Attacks using VR

Reading Time: 3 minutesDue to the increasing number of terrorist-related attacks, researchers at Sheffield Hallam University have developed a new training method using virtual and augmented reality to better prepare police, first responders, and air workers called AUGGMED. Historically, training for counter-terrorism assignments has been neither standardized nor readily available. Instead, training includes real-world scenarios…

-

Titomic Launches ‘World’s Largest’ Metal 3D Printer in Australia

Reading Time: 3 minutesTitomic, the Australian industrial scale additive manufacturing company, has launched what it claims is the world’s largest metal 3D printer with a demonstration in its native Melbourne. The demo follows an MoU with Fincantieri Australia this week, which aims to evaluate how this technology can benefit maritime manufacturing processes. Titomic, the Australian…

-

Titomic Launches ‘World’s Largest’ Metal 3D Printer in Australia

Reading Time: 3 minutesTitomic, the Australian industrial scale additive manufacturing company, has launched what it claims is the world’s largest metal 3D printer with a demonstration in its native Melbourne. The demo follows an MoU with Fincantieri Australia this week, which aims to evaluate how this technology can benefit maritime manufacturing processes. Titomic, the Australian…

-

Interview with Ultimaker: Looking at the Ultimaker S5 and Shift Towards Professional Market

Reading Time: 13 minutesAll3DP travelled to Hannover Messe 2018 to witness the unveiling of the new Ultimaker S5 3D printer. To learn more about this professional-grade 3D printer and the company’s refined focus, we sat down with to Siert Wijnia, the co-founder of Ultimaker; and Paul Heiden, Senior VP of Product Management. Back in 2011, a…

-

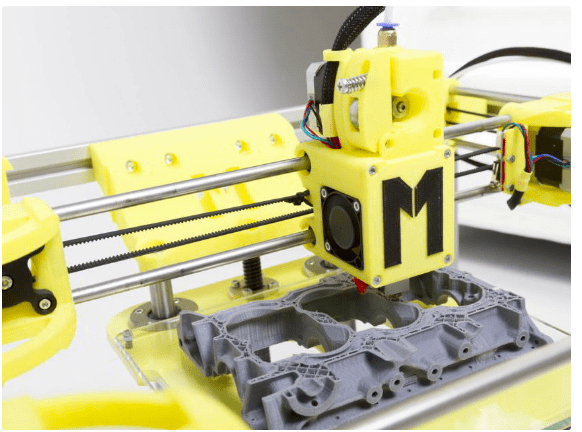

Yamaha’s Bike Racing Team Uses Mark One 3D Printers Inside The Pit Box

Reading Time: 3 minutesThe Mark One 3D printers will be installed in the pit box to make it easier to replace parts at the last minute. The automotive industries have long been using additive manufacturing to prototype car parts or even entire cars. In addition, 3D printers are increasingly being used by competitive racing teams…

-

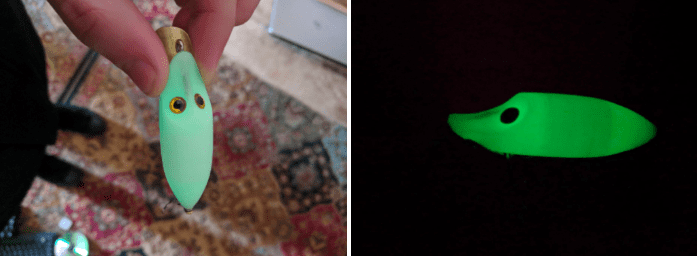

Blogger 3D Prints Replicas of Collectible Fishing Lures

Reading Time: 3 minutesAre you a fishing lure collector who doesn’t want to risk losing their collectibles – why not create replicas of your prized possessions using a 3D printer? That’s exactly what fisherman/blogger Hunter Irving did. Hunter Irving is an avid fishing enthusiast who started a collection of Heddon River Runt fishing lures when…

-

3DPrinterOS Partners with Microsoft to Make Adopting 3D Printing Easier

Reading Time: 3 minutes3DPrinterOS is working with Microsoft to scale its “factory of the future” 3D printing cloud platform. The idea is to use Microsoft’s Azure cloud computing service to make its own cloud platform more powerful and scalable. 3DPrinterOS, the cloud 3D printer management, and infrastructure company have now been around for five years. From…

-

SodaStream Creates 3D Printed Bottle Hats for Royal Wedding Charity Auction

Reading Time: 2 minutesIn celebration of the upcoming nuptials between Britain’s Prince Harry and American Actor Meghan Markle, SodaStream has turned to 3D printing to create a limited set of bottle hats for a special auction. Few things elicit quite as much international euphoria and bewilderment as a Royal wedding. And in little over three…

-

3D Printing Used to Develop Walkie-Talkie Device That Helps Parents Keep Tabs on Kids

Reading Time: 4 minutesThe Relay is a safer alternative to smartphones created for parents worried about keeping in touch with their kids when they’re out and about. Republic Wireless used 3D printing technology to speed up the prototyping process and develop new iterations of the walkie-talkie styled device. Being a parent is no easy feat,…

-

US Marines Receive Intensive Training to Use LulzBot 3D Printers

Reading Time: 3 minutesTraining company Building Momentum are using LulzBot 3D printers to train the US Marines in creative problem solving and innovation. Building Momentum is a company based in Alexandria, Virginia which provides consulting on science, engineering, and technology development to defense, education, corporate, and entrepreneurial organizations. Since 2015, Building Momentum has been helping…

-

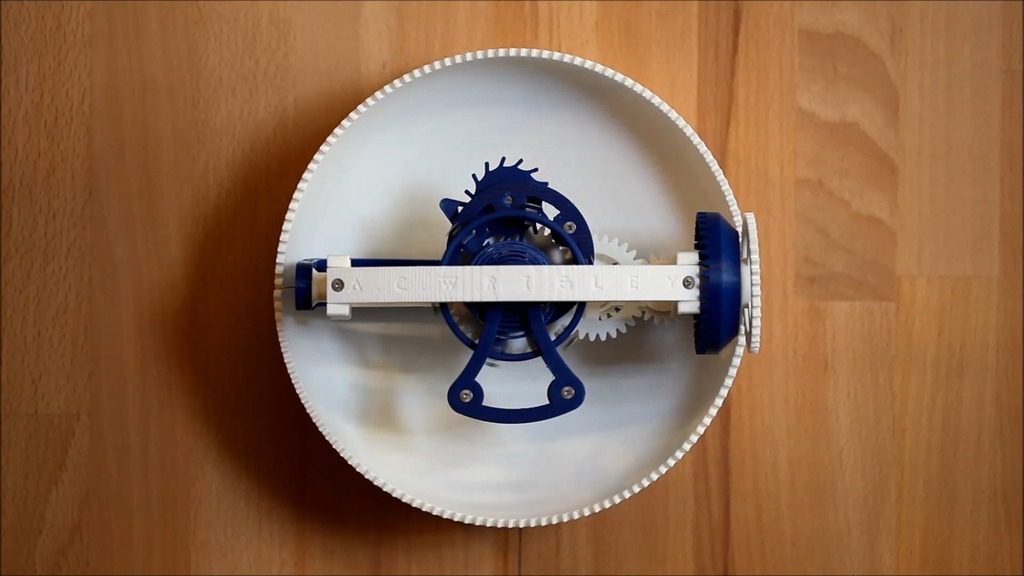

Hawk Eye is a 3D Printed Triple-Axis Tourbillon

Reading Time: 2 minutesInspired by the Deep Space Tourbillon of Vianney Halter, the Hawk Eye is a fully functioning, 3D printed triple-axis tourbillon. This complex horological mechanism with 70 moving parts will soon be available to download from Thingiverse. The tourbillon is a fascinating horological marvel which ranks among the highest achievements in watchmaking. Patented…

-

This Millennium Falcon-Themed Nissan is Partially 3D Printed

Reading Time: 2 minutesAs the hype machine cranks into gear ahead of this month’s release of Solo: A Star Wars Story, Lucasfilm and Nissan have partnered to create a Millennium Falcon-themed Nissan Rogue. Missing the obvious May 4th marketing opportunity by some weeks, Solo: A Star Wars Story will hit the silver screen later this…

-

Weekend Project: Create a 3D Printed Pocket Microscope from E-Waste

Reading Time: 4 minutesHave an ancient DVD or CD drive collecting dust in your garage? You can use your 3D printer and a recycled lens to create an e-waste pocket microscope. For those of us living in the modern world, it’s hard to imagine surviving without the electronics that have become such an integral part…

-

South Korea Develops Virtual Reality Movies for Cinema-Goers

Reading Time: 3 minutesVirtual Reality is making it to cinemas in South Korea with film tech labs and visual effects houses rapidly creating popular content. Cinema-goers are fully immersed with both VR and 4DX which brings feel, touch and smell to the experience. From the beginning of the 1900s until now, people have been enjoying…

-

Weekend Project: Make Your Garden Glow with 3D Printed LED Flowers

Reading Time: 4 minutesWant to give your 3D printer the green thumb? Autodesk and Instructables content creator Becky Stern shares a project on how to make 3D printed light-up flowers with LED lights. FDM desktop 3D printing has opened up a new world of possibilities when it comes to making customizable and decorative objects. By…

-

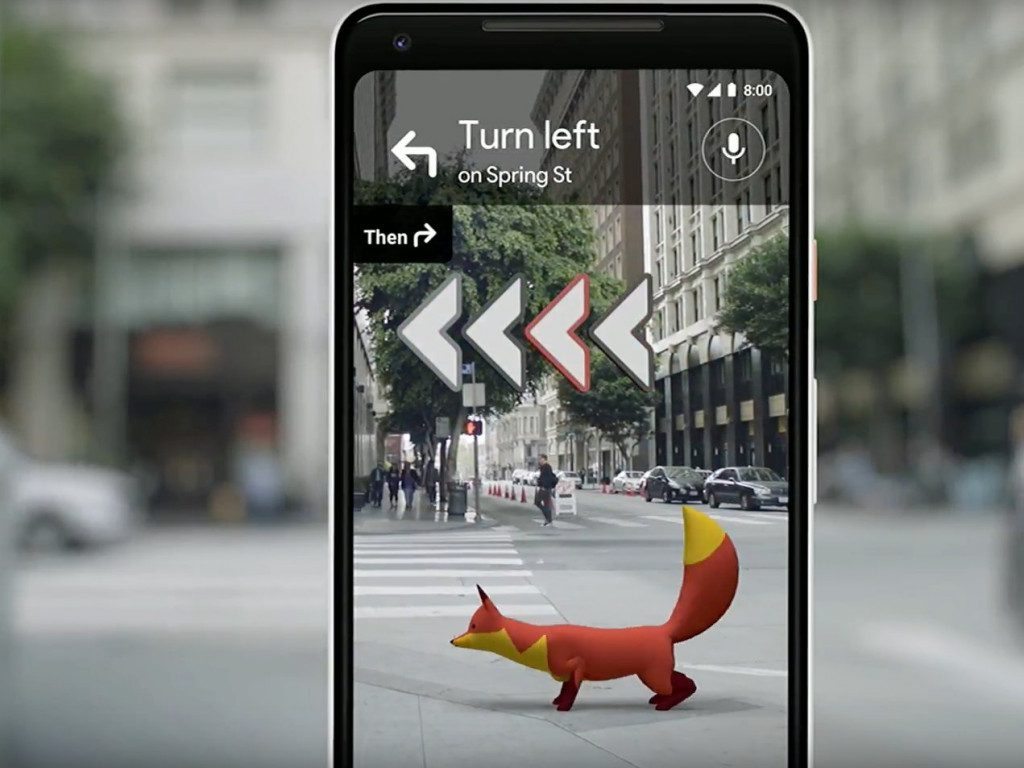

Google Maps to Improve Walking Navigation with AR Fox and Giant Arrows

Reading Time: 3 minutesAt Google’s I/O Developers conference this week, the company’s Vice President, Aparna Chennapragada, demonstrated how AR could be used to improve navigation when using Google Maps. The result is a cute AR fox and huge arrows to point you in the right direction. How often do you find yourself relying on Google…

-

Export Collada Files from New PSVR Painting App

Reading Time: 3 minutesA new VR painting application has just released for PlayStation 4. Titled CoolPaintrVR, the app allows you to paint and sculpt in VR and export your creations to 3D modeling software and platforms. Besides the throng of stellar games and weirdness-generating virtual social spaces, the rise of home virtual reality (VR) technology…

-

3D Printed Telegraph Replicates Ezra Cornell’s 1844 Original

Reading Time: 3 minutesMade with 3D scanning and 3D printing, a replica of Ezra Cornell’s telegraph machine from 1844 goes on display at Cornell University Library. In the history of communications, American businessman and philanthropist Ezra Cornell played a significant role. In 1844, his personal telegraph machine received the world’s first telegraph message sent by…

-

This 3D Printed Skim Reaper Can Prevent Credit Card Fraud

Reading Time: 3 minutesCredit card skimming is a disease. Meet the cure. The New York City Police Department is testing a “skim reaper” to detect and prevent credit card fraud. It’s based on a 3D printed prototype by researchers from the University of Florida. Cyber-security researchers from the University of Florida are working with the…

-

Made In Space Wins NASA Contract for Next-Gen ‘Vulcan’ 3D Printer

Reading Time: 2 minutesCalifornia-based company which built the two 3D printers aboard the International Space Station (ISS) secures a NASA contract to continue developing its next-generation Vulcan manufacturing system. As the name implies, Made in Space is a company that specializes in additive manufacturing in space. And they’re pretty established, too. The start-up already has…