Schlagwort: diy

-

Microsoft Flight Simulator 2020 Gameplay Review + Bonus Videos

Reading Time: 2 minutes The Real Deal Simualtor: If you want to buy your own, here you can do so: Panel A320 Desktop Captain Description from the website: FO side of the Panel A320 Desktop is now available in option ! It functions with only one external computer and can be connected easily with…

-

Hack your old Raspberry Pi case for the Raspberry Pi 4

Reading Time: 2 minutesHack your existing Raspberry Pi case to fit the layout of your new Raspberry Pi 4, with this handy “How to hack your existing Raspberry Pi case to fit the layout of your new Raspberry Pi 4” video! Hack your old Raspberry Pi case to fit your Raspberry Pi 4 Hack your…

-

Upgrade a sewing machine into an automatic embroidery rig

Reading Time: 2 minutesUpgrade a sewing machine into an automatic embroidery rig Arduino Team — November 26th, 2018 A needle and thread is extremely useful if you need to fasten a few pieces of fabric or sew on a button, and a sewing machine takes things up several notches in speed an accuracy. This venerable…

-

Transform A Wooden Pallet Into 5 Stenciled Signs Perfect For Fall

Reading Time: < 1 minute[unable to retrieve full-text content] Website: LINK

-

![9 Simple And Delicious Potato Recipes That Your Friends Will Love [video]](data:image/svg+xml;charset=utf-8,%3Csvg xmlns%3D'http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg' viewBox%3D'0 0 300 300'%2F%3E)

9 Simple And Delicious Potato Recipes That Your Friends Will Love [video]

Reading Time: < 1 minute[unable to retrieve full-text content] Website: LINK

-

Take Your Ikea Coffee Table From Bland To Grand With An Inlay Stencil Kit

Reading Time: < 1 minute[unable to retrieve full-text content] Website: LINK

-

No-Sew Unicorn Hoodie

Reading Time: < 1 minute[unable to retrieve full-text content] Website: LINK

-

Here’s How I Turned Our Formal Living Room Into A Home Office

Reading Time: 8 minutesWhen we purchased our home last year, we started out using one of our three bedrooms as a home office. Our plans were to eventually convert the unused formal living space in the front of the house to a home office down the road, as we have a bigger family room in…

-

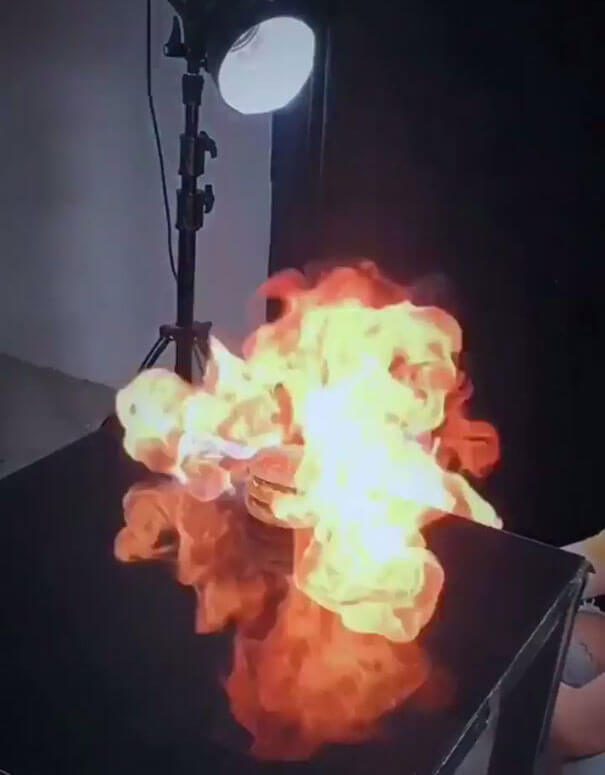

Genius Chinese Company Creates High-End Food Ads Using Super Low-Budget Items, And Result Is Amazing

Reading Time: 2 minutesOne way a filmmaker or photographer can prove they’re creative is making something wonderful with a low budget. We have already featured some photographers who tackled this subject, but now a collective of people are making the same point using video. Recently, one Chinese studio shared exclusive behind-the-scenes footage of their food…

-

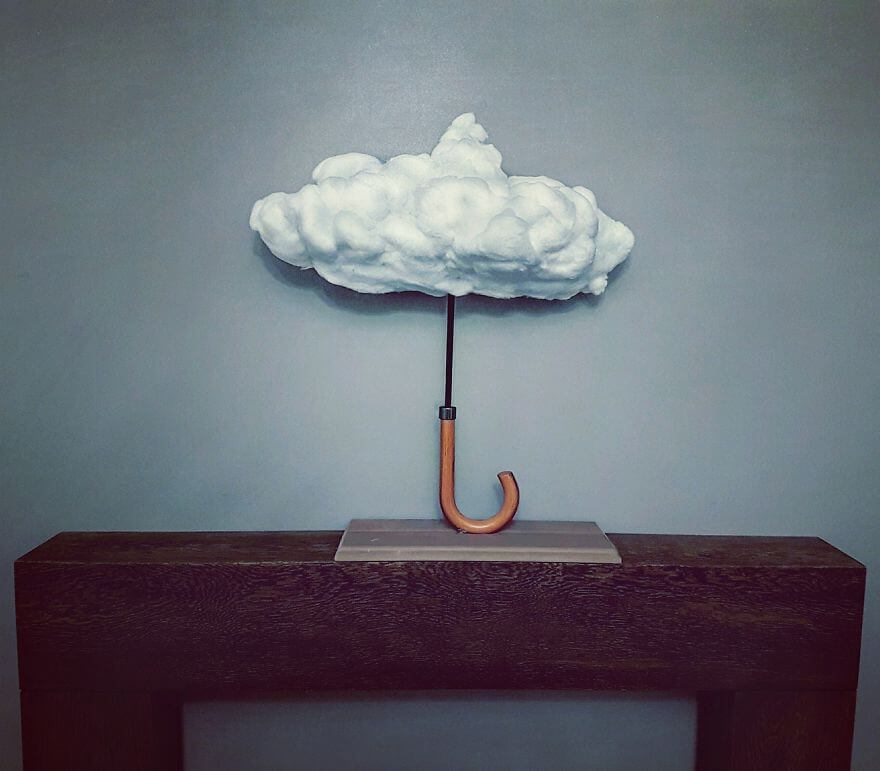

I Create Robots And Other Contraptions For Fun

Reading Time: 3 minutesMy name is Terry. I like to make things (constantly). Here are some of the things I have made over the years. I just make these things for fun, no other reason. I am interested in all the sciences, and sometimes incorporate those interests into my work. An example of this would…

-

3D Printing an Personalized Engagement Ring for a Proposal

Reading Time: 3 minutesBefore proposing to his girlfriend, Dan Ko decided that everything had to be perfect, including the engagement ring. So, he truly personalized his proposal by 3D modeling and printing a ring which he knew his future wife would love. For his wedding back in March 2016, Dan Ko, a self-proclaimed “tech enthusiast and…

-

Weekend Project: 3D Print a Sleek 7-Segment LED Clock

Reading Time: 4 minutesCombine function and form with this 7-segment LED clock, designed by Kansas-based maker Leonard Lee. It reliably delivers accurate time — down to the second — while at the same time adding a little light to your life. How many times have you squinted across a room trying to read the time…

-

Weekend Project: Take Flight With This 3D Printed V911 Micro Flying Wing

Reading Time: 3 minutesHow’s the local weather forecast looking this weekend? Why not 3D print your own micro flying wing to soar beyond the kites and frisbees at the park. Designed by Thingiverse user drcameron, this RC wing attachment will have you soaring through blue skies with style. With projects like OpenRC taking the 3D…

-

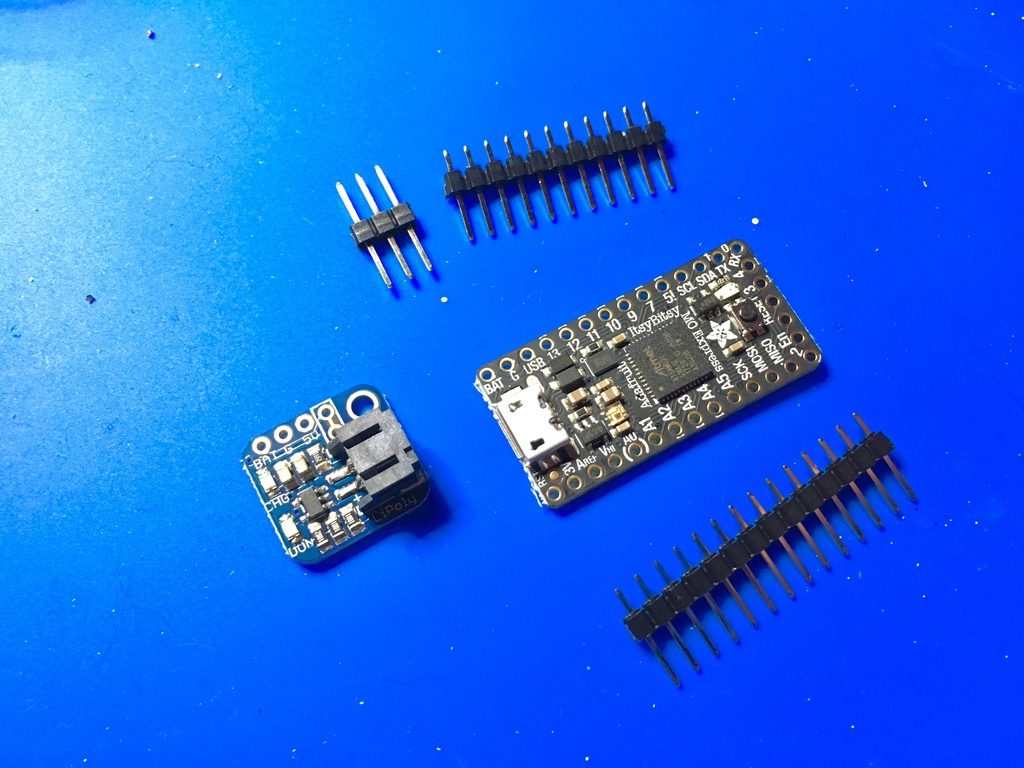

Weekend Project: 3D Printed NeoPixel Butterfly Ring That Flutters with Light

Reading Time: 4 minutesWant a 3D printing project that will hone your design and circuitry skills, all while giving you a butterfly ring that flutters with light? Then break out of that cocoon and build yourself this 3D printed NeoPixel butterfly ring. When used as a standalone technology, 3D printing is capable of producing some…

-

Project of the Week: 3D Printed High-Speed Marblevator Mini Machine

Reading Time: 3 minutesMaker and Instructables regular Greg Zumwalt has created the 3D printed Marblevator Mini, a marble machine with a high speed loop mechanism that can handle over 324,000 marble runs per day. Check out how you can build this jaw-dropping project yourself! Most of us can remember the childhood joy that arose when…

-

Weekend Project: 3D Printed Motorized Turntable for Photo & Video

Reading Time: 4 minutesWant to capture all 360 degrees of an object with your camera? Adafruit has recently shared a 3D printing project that shows you how to create an inexpensive turntable made for photographers and videographers. As anyone in the photography or film world knows, the many different types of production equipment that are…

-

Project of the Week: 3D Print a Solar-Powered Open RC Boat

Reading Time: 3 minutesWant to spend the summer days sailing the seven seas and soaking up the sun? Thingiverse user UniversalMaker shows us how to build a 3D printed Open RC Boat equipped with solar panels. With summertime approaching and warm weather abound, it’s the perfect time to head over to your local body of…

-

Weekend Project: Create a 3D Printed Pocket Microscope from E-Waste

Reading Time: 4 minutesHave an ancient DVD or CD drive collecting dust in your garage? You can use your 3D printer and a recycled lens to create an e-waste pocket microscope. For those of us living in the modern world, it’s hard to imagine surviving without the electronics that have become such an integral part…

-

Weekend Project: Make Your Garden Glow with 3D Printed LED Flowers

Reading Time: 4 minutesWant to give your 3D printer the green thumb? Autodesk and Instructables content creator Becky Stern shares a project on how to make 3D printed light-up flowers with LED lights. FDM desktop 3D printing has opened up a new world of possibilities when it comes to making customizable and decorative objects. By…

-

Weekend Project: Five Things to 3D Print for Your Cinco De Mayo Celebrations

Reading Time: 4 minutesAre you getting ready to celebrate the Mexican holiday of Cinco de Mayo this weekend? Prep for the festivities, which usually entail endless margaritas, music, and food, with some of these Cinco de Mayo-themed 3D prints! Today is May 5th, and while that might seem like an ordinary day to a majority…

-

Weekend Project: 3D Print Your Own Honeycomb-Designed Card Wallet

Reading Time: 3 minutesNeed a safe and sleek place to store your credit cards, gift cards, and your other wallet inhabitants? This fully 3D printed Card Wallet is extremely easy to make, and has a card pusher to give you instant access to your plastic money! Most of the projects we share at All3DP are…

-

Project of the Week: Wield the Power of the Infinity Gauntlet from New ‘Avengers’ Film

Reading Time: 3 minutesLooking forward to the release of Avengers: Infinity Wars? Why not become the most powerful villain in the Marvel universe with your own 3D printed Infinity Gauntlet. This weekend, Marvel fans will be flocking to the theatre to see the highly anticipated superhero film Avengers: Infinity Wars. The movie puts the Avengers up against the…

![9 Simple And Delicious Potato Recipes That Your Friends Will Love [video]](https://www.blogdot.tv/wp-content/uploads/2018/09/9-simple-and-delicious-potato-recipes-that-your-friends-will-love-video.jpg)