Schlagwort: sponsored content

-

Become Your Own Material Maker with the Felfil Evo Filament Extruder

Reading Time: 4 minutesThe Felfil Evo is an open-source 3D printer plastic extruder machine that allows you to create customized 3D printing filament from the comfort of your own home. Make your own materials from plastic pellets, flawed or old 3D prints, or plastic waste. With all of the brands and formulations crowding the 3D…

-

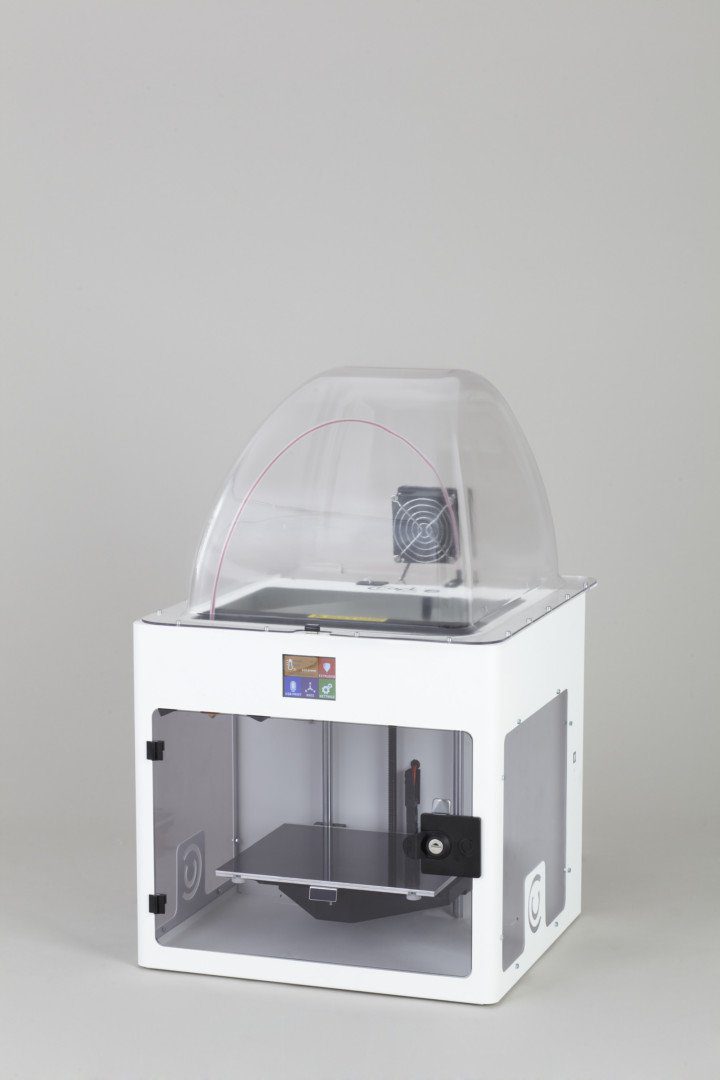

CraftBot Introduces the CraftBot 3 Dual 3D Printer to Expansive Product Line

Reading Time: 4 minutesCraftBot has added the new CraftBot 3 Dual to its expansive range of 3D printers. This professional-grade desktop machine offers dual extrusion printing, an advance filament monitoring system, and a 374 x 250 x 250mm build volume. The desktop 3D printer market has become increasingly crowded with endless options, making it difficult…

-

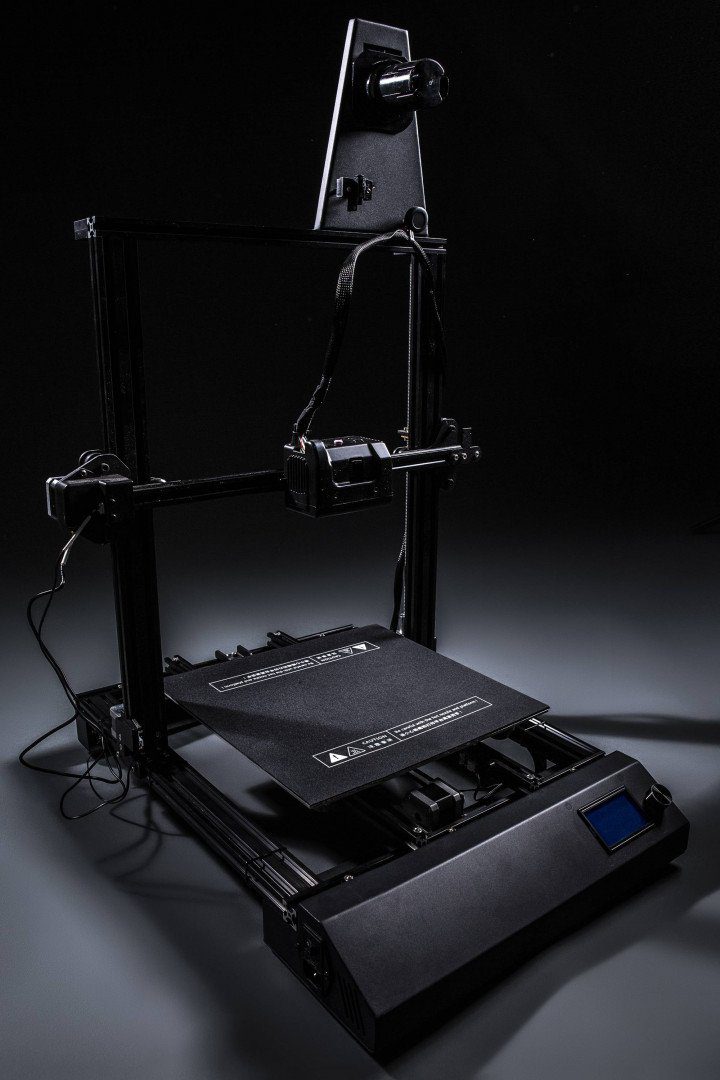

Copymaster 3D Set To Debut First Range of 3D Printers

Reading Time: 5 minutesCopymaster 3D is selling its first 50 3D printers for a 20% discount–meaning you could get one for as low as £399.20. First come first served. Learn more here. Copymaster 3D is a brand new player in the 3D printing world and has certainly raised a few eyebrows since it burst onto…

-

Dynamism Adds New Ultimaker S5 3D Printer to Extensive Portfolio

Reading Time: 4 minutes3D printing solutions provider and reseller Dynamism has added the new Ultimaker S5 3D printer to its product range. The company will provide customers with pre-order advice, on-site or web-based installation and training, and quality-assurance for Ultimaker’s new 3D printer. Despite rapid advancements, desktop 3D printing is still the new tech on the…

-

Raise3D is Pathfinding “Flexible Manufacturing” with Customized Solutions

Reading Time: 4 minutesRaise3D is striving to offer “Pathfinding for Flexible Manufacturing” through customized 3D printing solutions for vertical markets. To jumpstart the campaign, the new company has recently unveiled the Pro2 Series, a new series of desktop 3D printers made with industrial-grade components. Additive manufacturing has unquestionably disrupted certain aspects of industrial manufacturing, particularly…

-

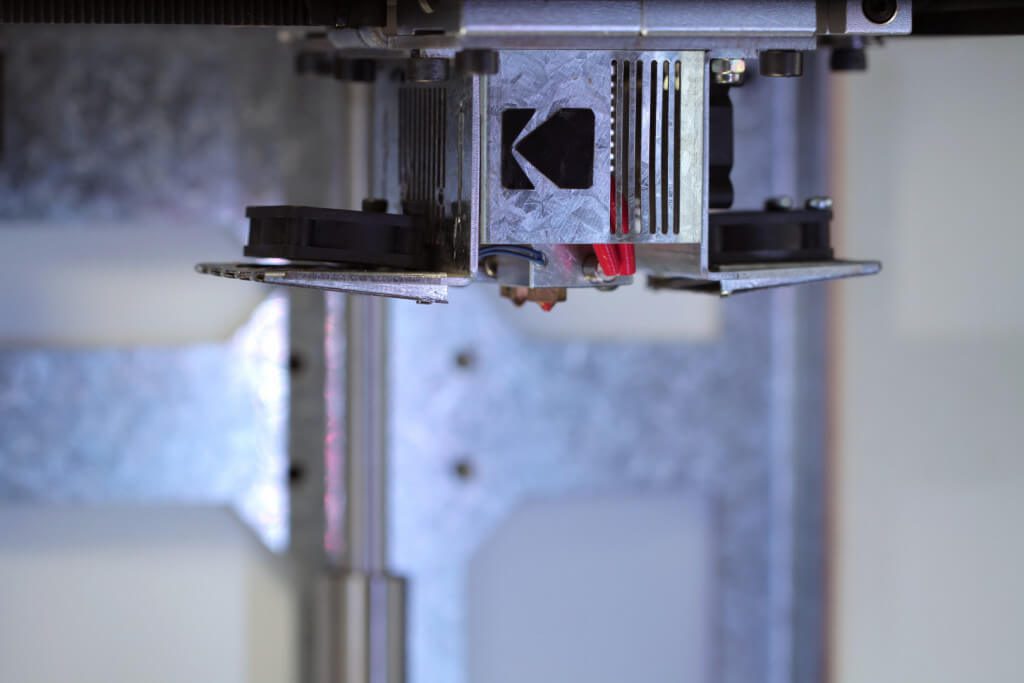

Kodak celebrates 130th Anniversary with Launch of New 3D Printing Ecosystem at CES

Reading Time: 3 minutesWhether it’s the legendary Kodachrome film or high-tech printing machines, Kodak has always been at the forefront of science, art, and industry. To celebrate its 130th anniversary, Kodak will be presenting the new Super 8 and its first Portrait 3D Printer at the Consumer Electronics Show this January. But if you just…