Schlagwort: Automotive

-

Humanetics is 3D Printing Crash Test Dummies That Resemble Elderly People

Reading Time: 3 minutesThe crash test dummy manufacturer Humanetics is using Markforged’s 3D printing technology and Onyx carbon-composite material to produce dummies the resemble elderly drivers, helping them accurately reflect injuries that could occur in a real car accident. Car crash testing is an integral part of ensuring vehicle safety, and brave human-like dummies have…

-

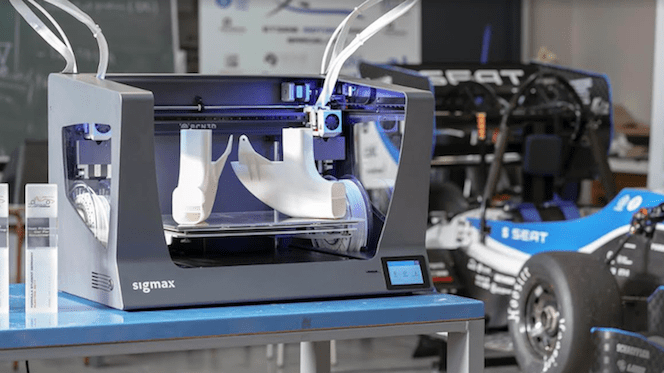

ETSEIB Motorsport Uses BCN3D Sigmax 3D Printer to Develop Racing Car for Formula Student Competition

Reading Time: 3 minutesETSEIB Motorsport, the automotive engineering team from the Polytechnic University of Catalonia, is now using 3D printing from BCN3D to help develop racing car parts for the Formula Student competition. Formula Student is a competition between students from universities worldwide with a focus on excellence in engineering. To enter the competition, teams are required to design,…

-

BMW Mini Commemorates Royal Wedding with Unique Car Design

Reading Time: 3 minutesBMW has created a special-edition Mini to celebrate the royal wedding of Prince Harry and Megan Markle. Boasting a hand-made graphic print and 3D printed details, the car will be auctioned off for charity. What could be more British than a royal wedding? A one-of-a-kind Mini Cooper S with a bold graphic…

-

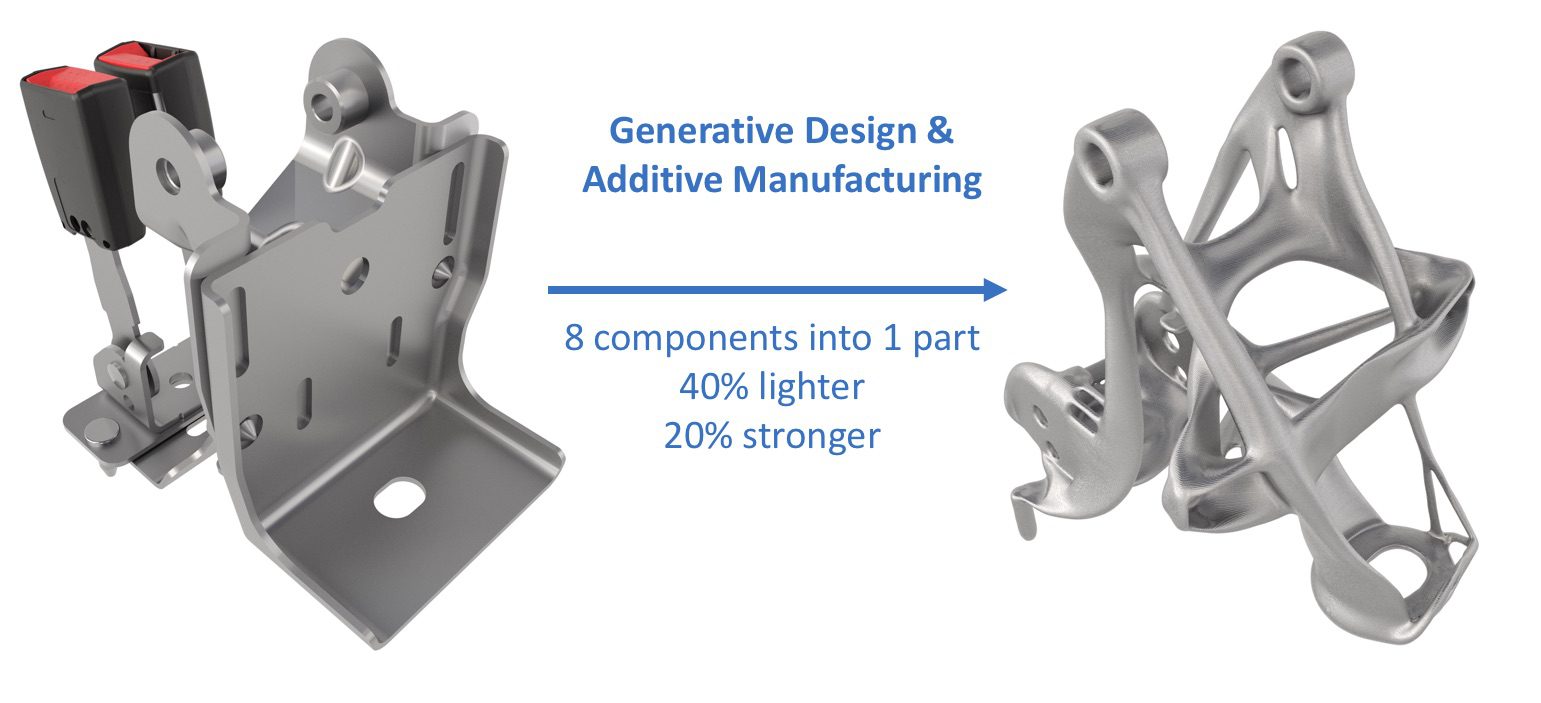

GM and Autodesk Using Additive Manufacturing for Lighter Vehicles

Reading Time: 3 minutesGM is using Autodesk’s generative design technology and additive manufacturing to fabricate lighter automotive parts; this seat bracket is 40% lighter and 20% stronger than its predecessor. General Motors is using generative design software by Autodesk to develop the next generation of lightweight vehicles. According to the automaker, the new technology will…

-

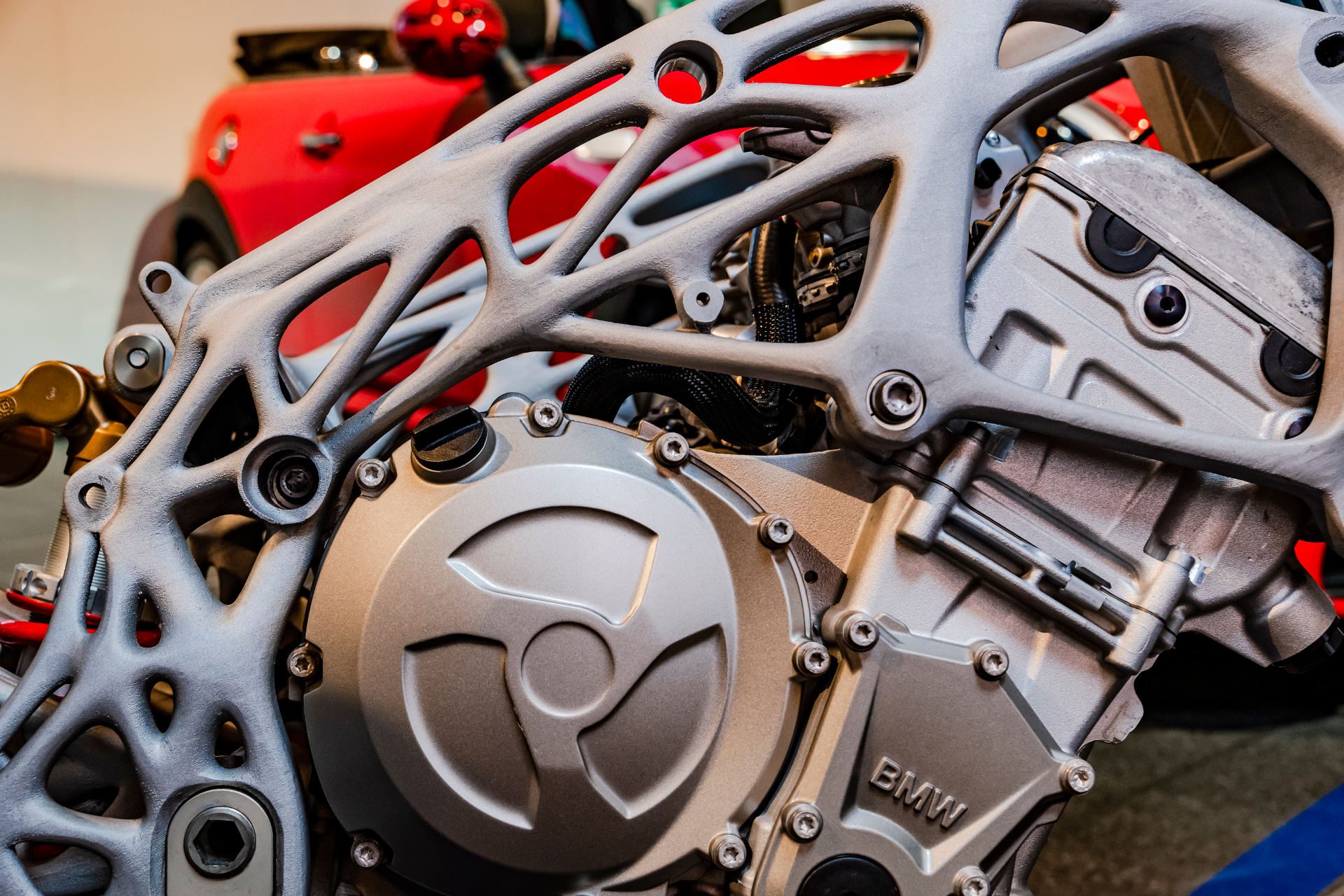

BMW to Establish Additive Manufacturing Campus in Munich

Reading Time: 4 minutesWith a total investment worth over €10 million, automotive giant BMW will open an industrial scale 3D printing campus in Munich, Germany in early 2019. The BMW Group is investing more than €10 million in a new Additive Manufacturing Campus. Located in Oberschleissheim, just north of Munich, the facility will ensure the…

-

MINI Launches 3D Printing Service to Offer Customized Car Accessories

Reading Time: 3 minutesThe automotive company MINI has launched MINI Yours Customised, a new 3D printing service that will allow customers to design custom interior and exterior trim pieces and have them 3D printed for their car. Many people believe that cars, much like dogs, tend to reflect the personality of the owner. The bubbly and…

-

Drive Into the Holiday Season With 3D Printable BMW Christmas Ornaments

Reading Time: 3 minutesBMW celebrates the holiday season and 3D printing technology by releasing STL files of its iconic logo, the famous BMW Welt, a set of wheels, and more. Of all the industries that have taken interest in advancing 3D printing technology, none seem as invested as the automotive sector. From rapid prototyping to…

-

Video: Death by 2JZ beats old age any day – This stunning, wide body, single turbo Toyota Supra is a gun metal grey bullet pushing 930hp. Will try and kill you on full boost!

Reading Time: 2 minutes“What an insane day behind the wheel of Marcel’s stunning JDM Mk.4 Toyota Supra. As a street car this widebody, single turbo, and gun-metal grey bullet of an import is ready for just about anything to challenges it. With a 2JZ engine under the hood pushing 930 HP to the rear wheels,…

-

McLaren Automotiv entwirft den Rennwagen der Zukunft exklusiv für GT Sport

Reading Time: < 1 minutezum Release am 18. Oktober präsentiert Gran Turismo Sport den neuesten GT Vision Rennwagen. In enger Zusammenarbeit mit McLaren entstand der Ultimate Vision Gran Turismo, der exklusiv für den Titel auf PlayStation 4 konzipiert wurde. Der Ultimate Vision Gran Turismo zeigt das Designdenken der Zukunft – neben mehr als 1000 PS…