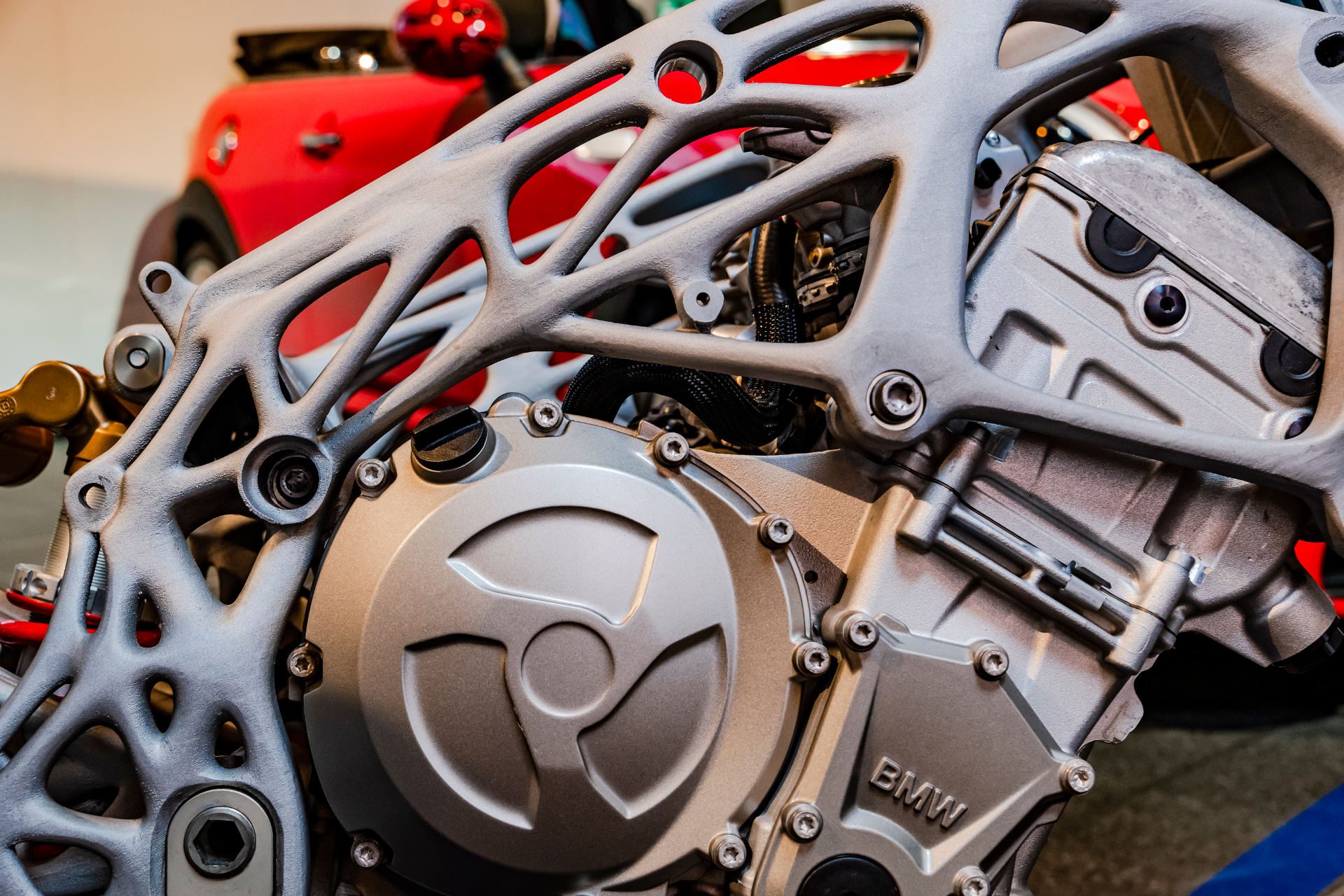

Carmaker BMW showed a 3D printed motorcycle frame at their Digital Day 2018 in Munich, an S1000RR superbike with a frame and swing arm fabricated using metal powder laser melting.

Don’t Miss: BMW to Establish Additive Manufacturing Campus in Munich

Every year, the BMW Group hosts a Digital Day at their illustrious headquarters in Munich. It’s a platform for the automaker to showcase some of their latest and greatest developments in automotive technology.

Front and center to these innovations, naturally, is additive manufacturing. The group is already using 3D printing to produce car parts, but the presence of a radical 3D printed motorcycle frame this year showed that the technology still has plenty of road to run.

The S1000RR superbike features a 3D printed aluminium chassis and swingarm. Details on the precise construction method used on the superbike are not provided, but it’s a safe bet that it’s metal powder laser melting.

This is a process where a laser fuses layers of metal powder in a vat to form a shape, layer by layer. BMW is already using this technique for their cars to produce lighter but structurally stiffer components.

3D Printed Motorcycle Frame is Showpiece of Digital Day 2018

Beyond the eye-candy of a 3D printed motorcycle frame, the BMW Group also drew attention to other areas of their 3D printing activities.

An additively manufactured water pump wheel was fitted in DTM racing cars for the first time back in 2010. And the new BMW i8 Roadster features a soft-top cover with an aluminium bracket made using a metal powder laser melting technique.

Elsewhere, the new MINI Yours Customized product line enables customers to personalize the design of selected components and then have them produced via 3D printing.

Last but not least, there’s the grand opening of the Additive Manufacturing Campus at the BMW Group Research and Innovation Centre (FIZ) in Munich in Spring 2019.

Overall, the advantages to the BMW Group are clear; 3D printing provides them with the ability to custom-build highly-complex objects. That, and they can rapidly prototype new components quickly and cheaply. Indeed, the automaker says that it’s already producing over 140,000 prototype parts per year.

Source: BMW Group

Website: LINK

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.