Schlagwort: 3D Printing Industry

-

ZMorph VX – Review the Facts of this Multitool Machine

Reading Time: 3 minutesThe magical multitool machine gets upgraded with the ZMorph VX. Review the facts on this 3-in-1 3D printer, CNC mill, and laser engraver. Are you ready for the next generation of multitool 3D printer? Is the world even ready? Nobody knows for sure, but Polish company ZMorph says to hell with the…

-

FDM vs SLA – 2018 3D Printing Technology Shootout

Reading Time: 7 minutesCheck out our FDM vs SLA Shootout. We simply explain the differences between these 3D printing technologies, and which to use for which application. FDM vs SLA: Explained The Prusa i3 MK3 is one of the finest consumer 3D printers you can get. It uses FDM technology to get things printed. (Source: ALL3DP)…

-

Arevo Boosts Expansion of Carbon Fiber 3D Printing With $12.5 Million Funding Round

Reading Time: 3 minutesThe start-up has launched a unique carbon fiber 3D printing technology that allows for enhanced scalability. Through the latest cash injection, it hopes to commercialize the technology more quickly. Carbon fiber 3D printing is set to become a dominant trend in additive manufacturing over the next few years. This is driven in…

-

Experimental Ceramic Resin for the Form 2 Now Available

Reading Time: 2 minutesA new experimental Ceramic Resin is a now available for the Form 2 from Formlabs, making ceramic 3D printing the most affordable and accessible it has ever been for engineers and designers. Stereolithography specialists Formlabs have announced the availability of a special new material for their Form 2 desktop 3D printer. Their…

-

US Navy Awards GE $9 Million Contract for 3D Printing Research

Reading Time: 4 minutesGE awarded $9 million contract by US Navy to develop framework to rapidly 3D print replacement parts for ships, aircraft, and other critical military assets. The focus of the research is 3D printing with metal. A team of scientists at GE Global Research, the technology development arm for General Electric, have been…

-

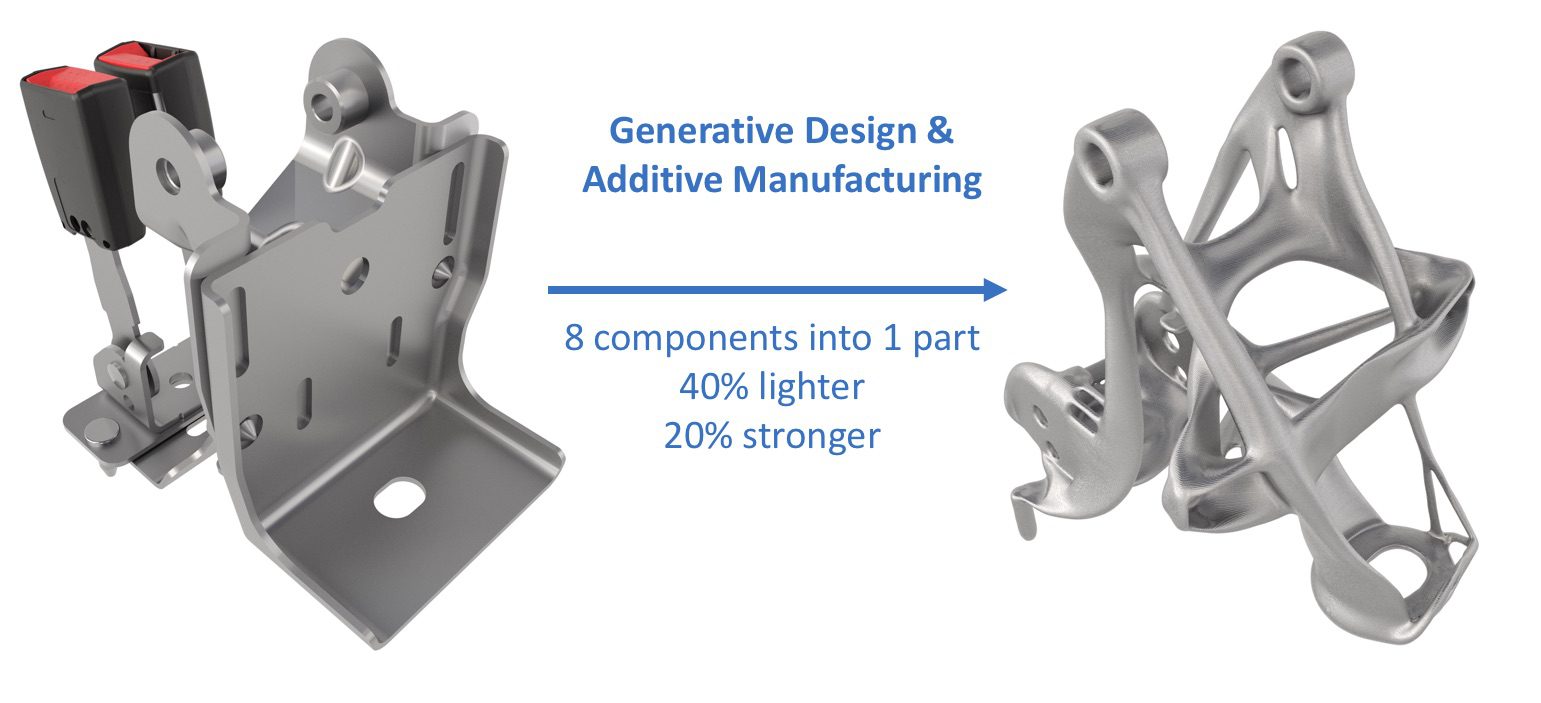

GM and Autodesk Using Additive Manufacturing for Lighter Vehicles

Reading Time: 3 minutesGM is using Autodesk’s generative design technology and additive manufacturing to fabricate lighter automotive parts; this seat bracket is 40% lighter and 20% stronger than its predecessor. General Motors is using generative design software by Autodesk to develop the next generation of lightweight vehicles. According to the automaker, the new technology will…

-

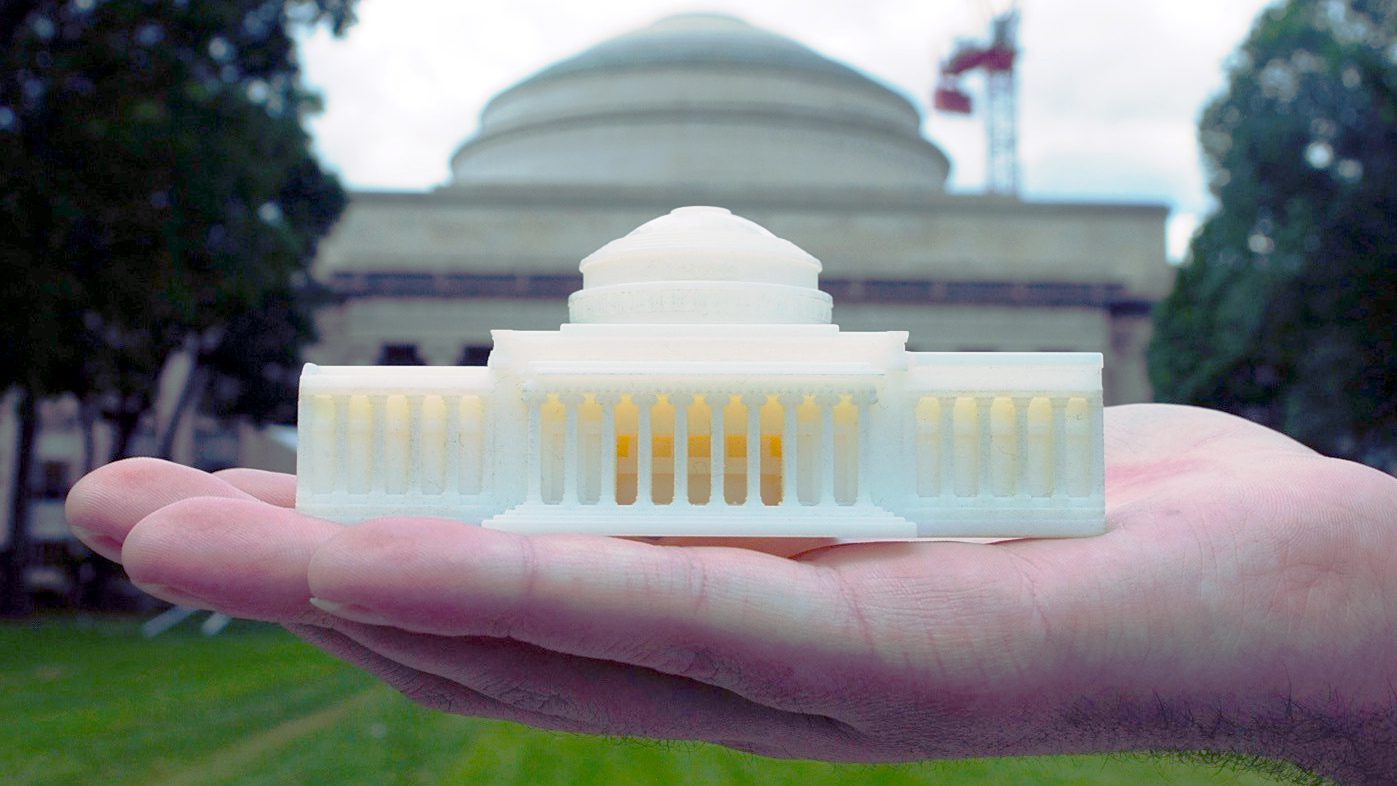

MIT and Boeing Collaborate on Additive Manufacturing Education

Reading Time: 2 minutesWith the expiration of key patents, availability of advanced digital modeling software, and improved hardware, additive manufacturing is on the verge of radically changing how products are designed, made and maintained. But a lack of understanding of its fundamental principles, applications, and business implications is proving to be a barrier to broader adoption.…

-

Ultimaker Launches Alliances Program to Improve 3D Printing Material Profiles

Reading Time: 3 minutesWith the new Ultimaker Alliances Program, users will be able to load preconfigured material profiles and 3D print settings from leading material manufacturers. Here’s a second big announcement from Ultimaker; the 3D printing company is embarking on a series of collaborative alliances with a number of global material companies to meet demand…

-

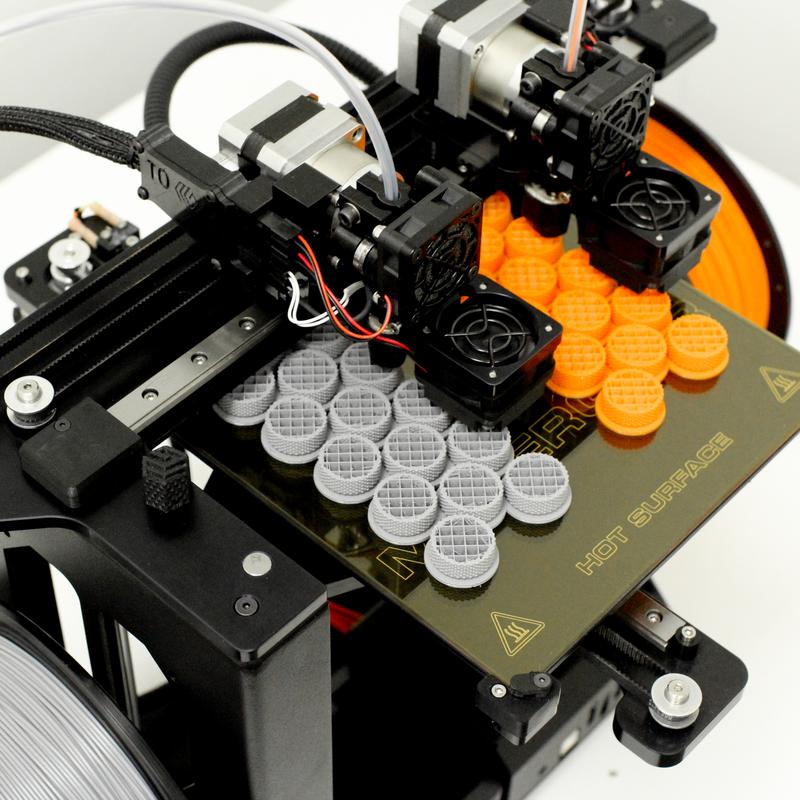

MakerGear Brings M3 Independent Dual Extruder 3D Printer to RAPID + TCT

Reading Time: 3 minutesAt the Rapid + TCT Event in Fort Worth this week, 3D printing manufacturer MakerGear are launching their new M3 Independent Dual 3D Printer and MakerGear Cloud Software. The 3D printing company MakerGear is cutting the ribbon on a new Independent Dual Extrusion (IDEX) system for their flagship M3 desktop 3D printer…

-

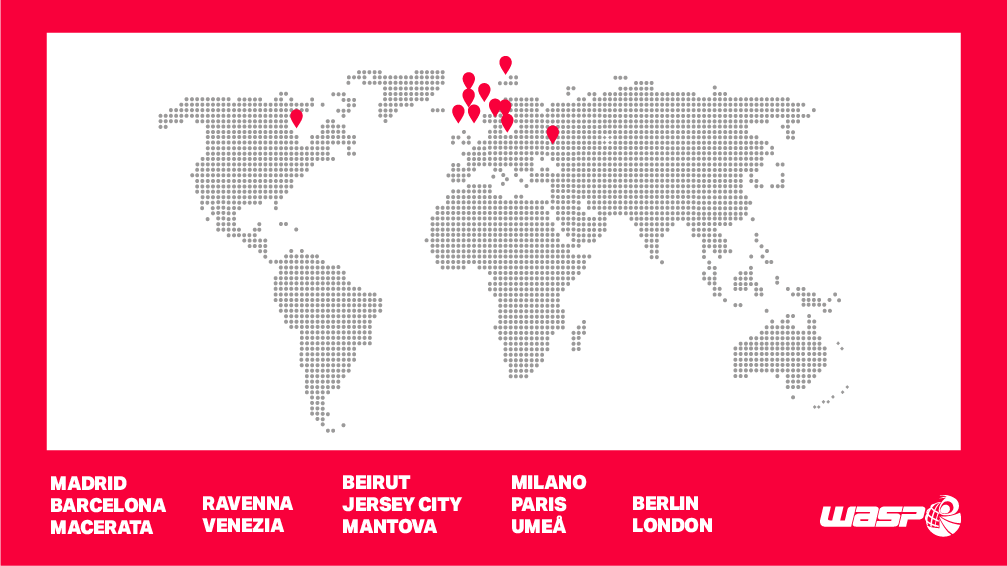

WASP Creates Hub Network Across the World

Reading Time: 3 minutesWASP, the Italian 3D printer manufacturer, has created the WASP Hub network and is expanding in Italy and across the world to cities including, Barcelona, London, Madrid, Paris, Umea, Jersey City and Beirut. There has been a lot of moving (and shaking) from WASP, the Italian 3D printing company WASP (short for “World’s…

-

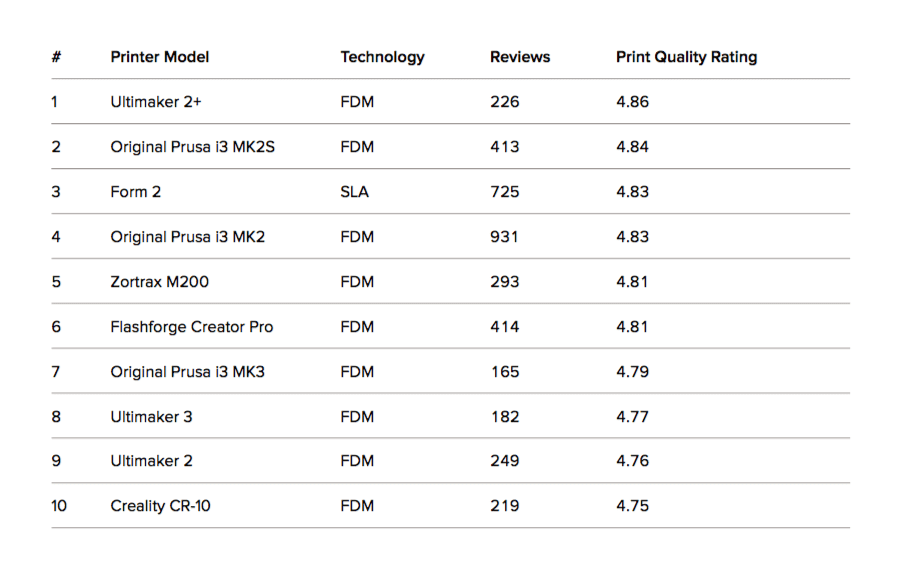

Ultimaker and Prusa Vie for Dominance in 3D Hubs Trend Report

Reading Time: 5 minutesUltimaker! HP! Prusa Research! New York City! Some fascinating insights into the 3D printing industry, courtesy of the latest 3D Hubs Trend Report. It’s the beginning of a new business quarter, and for 3D printing fanatics that means only one thing. It’s time for another 3D Hubs Trend Report. The 3D Hubs…

-

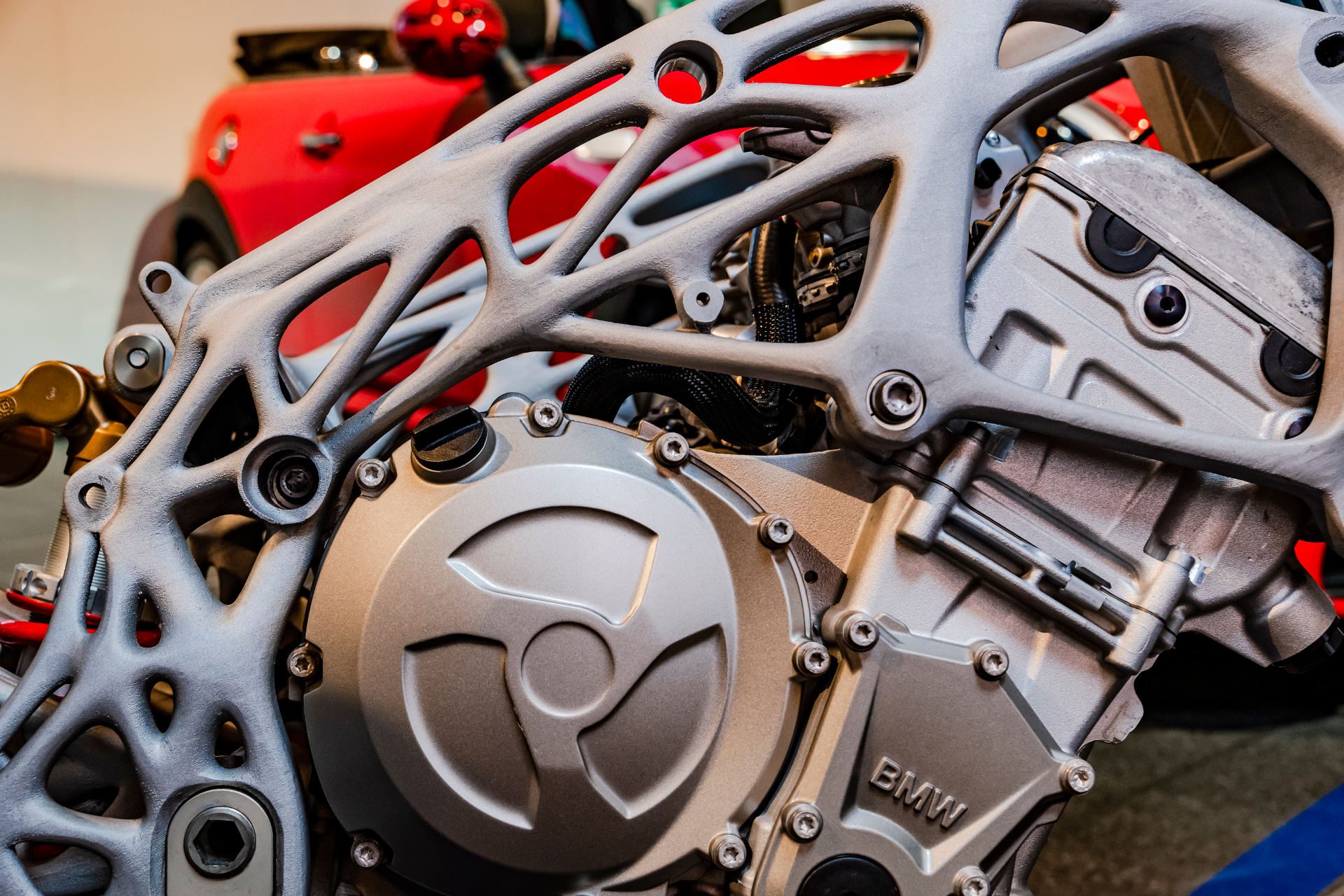

BMW to Establish Additive Manufacturing Campus in Munich

Reading Time: 4 minutesWith a total investment worth over €10 million, automotive giant BMW will open an industrial scale 3D printing campus in Munich, Germany in early 2019. The BMW Group is investing more than €10 million in a new Additive Manufacturing Campus. Located in Oberschleissheim, just north of Munich, the facility will ensure the…

-

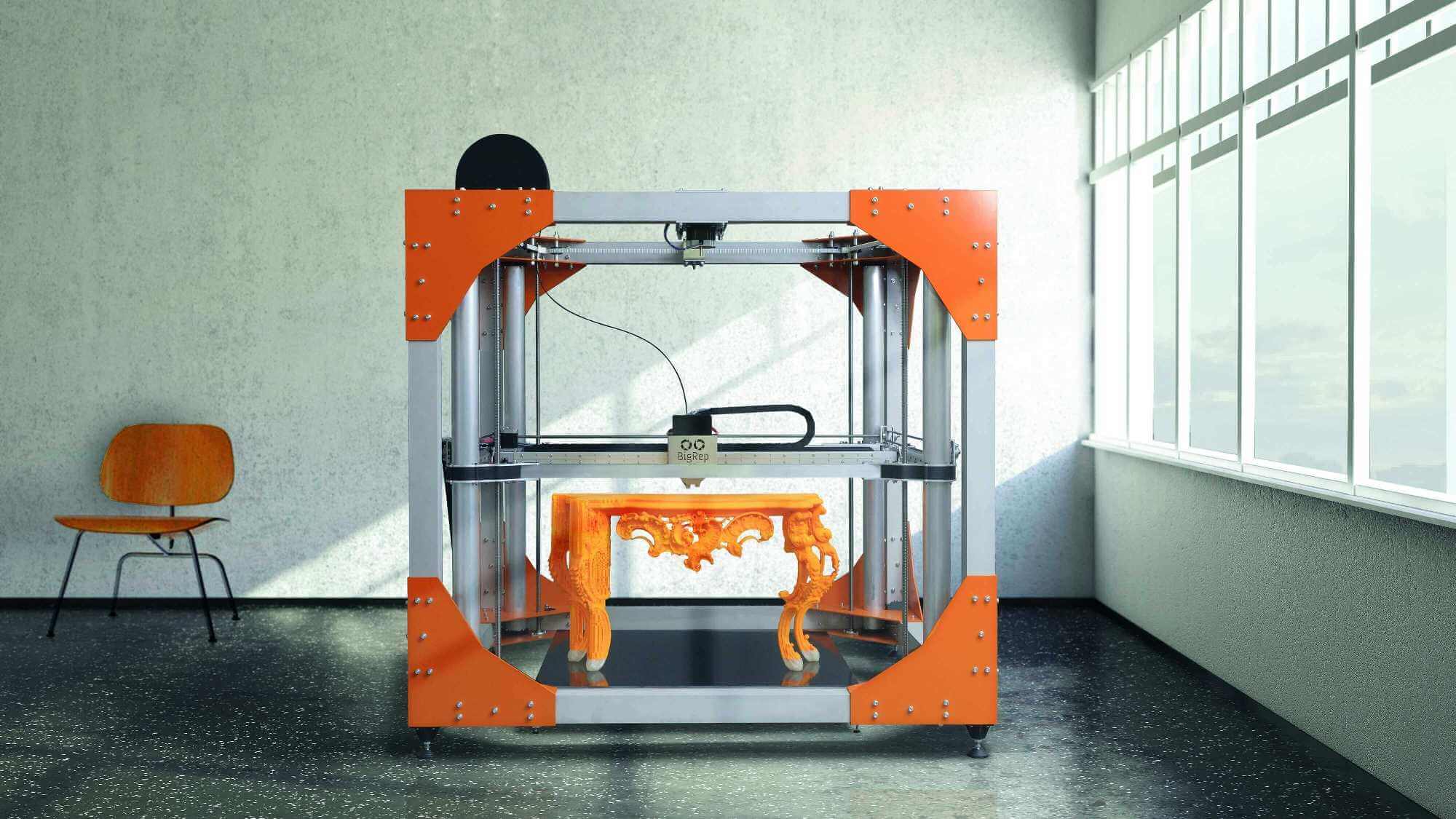

BigRep and Etihad Airways Engineering to Partner Up

Reading Time: 3 minutesBig Air meets Big Printing. BigRep and Etihad Airways Engineering announce plans to collaborate on developing next generation additive manufacturing solutions for the aerospace industry. Since it was first launched three and half years ago, 3D printer manufacturer BigRep has quickly become a world leader in large format 3D printing technology. Today,…

-

Digitally Augmented Additive Manufacturing Parts from Rize

Reading Time: 3 minutes3D printing company Rize has integrated digital rights management into physical 3D printed parts at the voxel-level; embedded QR codes can be used to provide compliance, authenticity and traceability. This week at the Additive Manufacturing Users Group (AMUG) in St. Louis, 3D printing company Rize announced the launch of digitally augmented parts.…

-

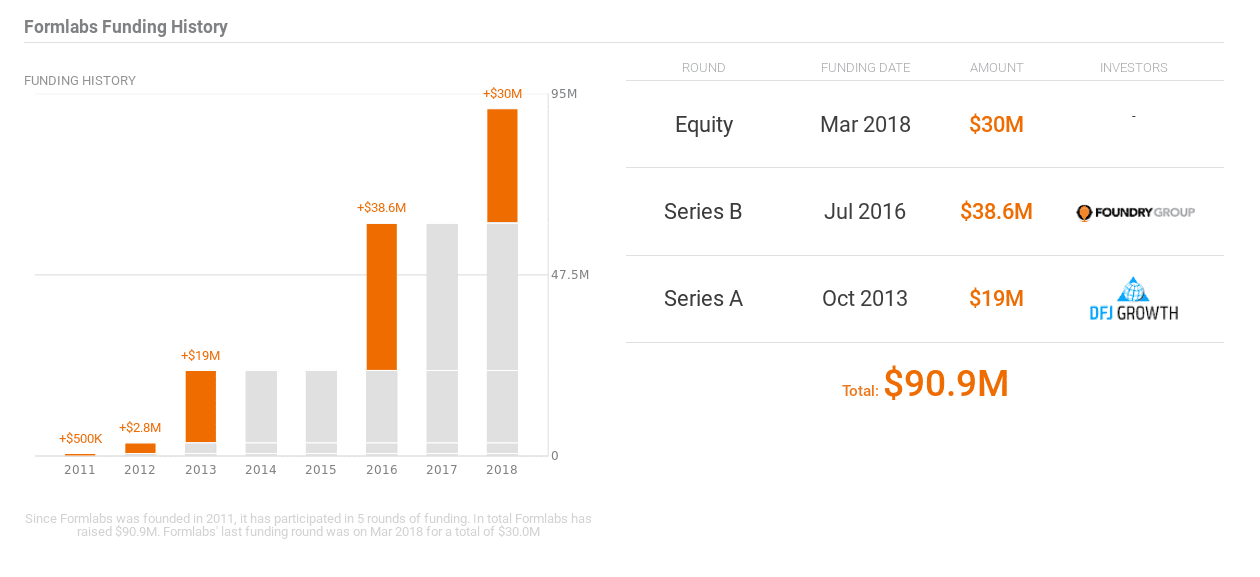

Formlabs Raises $30m in New Equity Funding

Reading Time: 3 minutesWith two major product launches on the horizon, 3D printing startup Formlabs bolster their war-chest with $30m in new equity funding. Market-leading 3D printer manufacturer Formlabs has raised $30 million in new equity funding, according to a document filed with the SEC this week. Together with CEO Maxim Lobovsky, the directors listed…

-

Significant Findings in 2017 Shapeways Transparency Report

Reading Time: 4 minutesThe 2017 Shapeways Transparency Report shines a light on how the world’s biggest 3D printing marketplace handles accusations of infringement of intellectual property. For those folks studying the shifting dynamics of the 3D printing marketplace, the Shapeways Transparency Report 2017 is as good a place to start as any. Published in March…

-

BigRep Launches New Pro Flex Filament for 3D Printing

Reading Time: 3 minutesThe new Pro Flex filament is a world first for the large-scale FDM industry, according to 3D printer manufacturer BigRep. BigRep is a large-scale FDM 3D printer manufacturer based in Berlin, and today they announce a new “innovation” in filaments that many users of standard desktop printers may find rather quaint. It’s…

-

New Metal 3D Printing Company Vulcan Labs Spun Out of Stratasys

Reading Time: 2 minutesIndustrial 3D printer manufacturer Stratasys has spun off a 3D printing operation into a new independent company called Vulcan Labs, specializing in powder-bed fusion technology. Stratasys, a leading producer of large commercial 3D printers, is launching a new company called Vulcan Labs, which will specialize in power-bed fusion additive manufacturing. The new…

-

Blow Molding Technology Guide

Reading Time: 6 minutesBlow Molding (also: Blow moulding) and the molding process of polymers is one of the pillars of industrial manufacturing. Without this technology, we wouldn’t have access to cheap glass or plastic bottles or mass-manufactured hollow containers. Blow molding allows industry players to produce parts and containers fast and cheap in high quantities. But…

-

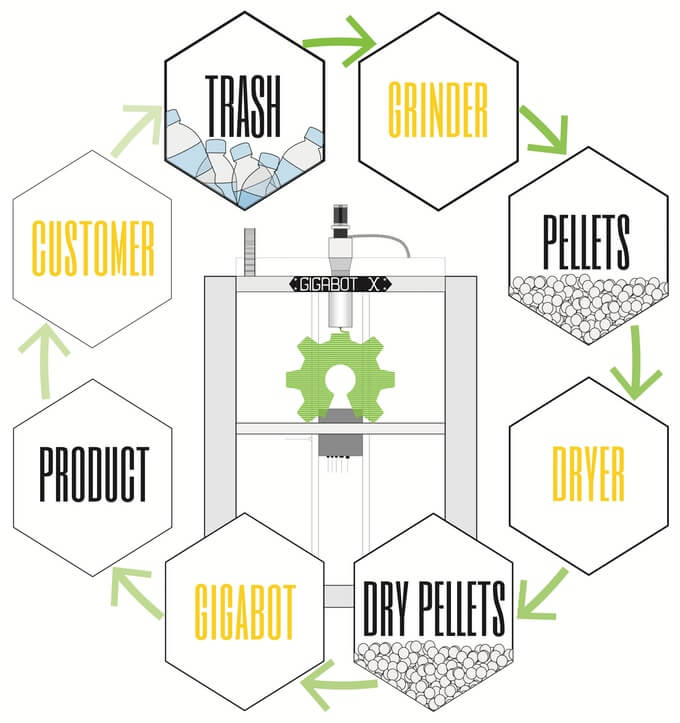

Gigabot X can 3D Print with Recycled Plastic Pellets

Reading Time: 3 minutesNow live on Kickstarter is the Gigabot X, a large-scale, direct pellet extrusion 3D printer for fabricating with recycled plastic. Houston, Texas might seem likely an unlikely location for a revolution in 3D printing, but this is where re:3d have announced the Gigabot X, an open source 3D printer that fabricates with…

-

Gregory Kress New CEO of 3D Printing Marketplace Shapeways

Reading Time: 3 minutesShapeways has a new CEO and his name is Gregory Kress; the company will continue its expansion into a 3D printing marketplace where creators can design, make, and sell their ideas. New York-based 3D printing service and marketplace Shapeways has announced the official appointment of Gregory Kress as CEO. He’ll be taking…