The new Pro Flex filament is a world first for the large-scale FDM industry, according to 3D printer manufacturer BigRep.

BigRep is a large-scale FDM 3D printer manufacturer based in Berlin, and today they announce a new “innovation” in filaments that many users of standard desktop printers may find rather quaint. It’s called Pro Flex, and it’s a flexible material with engineering grade properties for variety of applications.

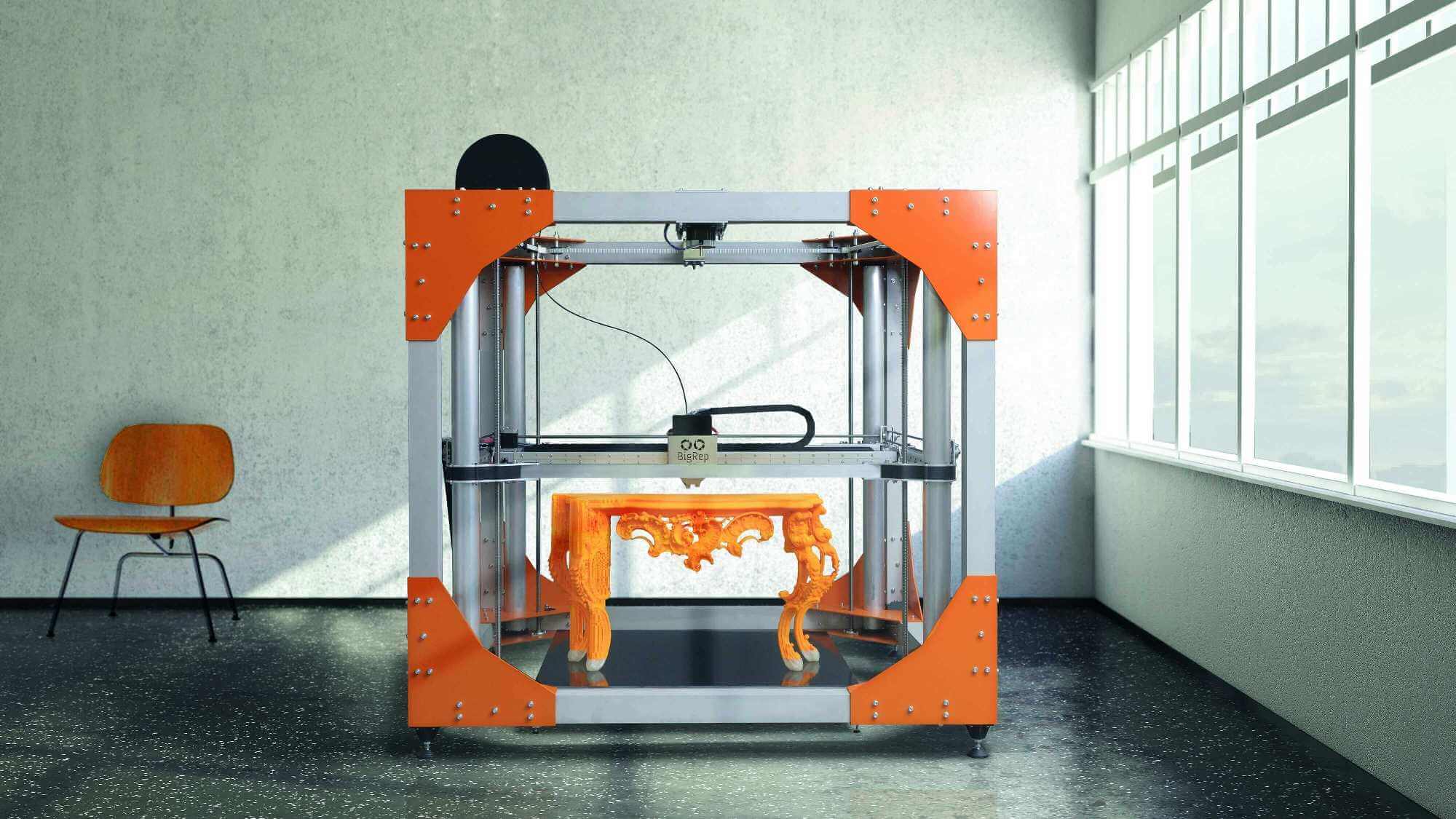

So yes, tinkerers with modestly sized fused deposition modeling machines will have probably experimented with flexible materials for a while now. But BigRap is confident that this is a world first for the large-scale FDM industry. Given the generous square meter build volume of a BigRep ONE, fabricating something like a bouncy castle with Pro Flex is a distinct possibility.

But of course, the new TPU-based material Pro Flex is meant for more serious applications, providing manufacturers and customers with a flexible engineering material that has been developed and tested to work in tandem with a standard BigRep ONE and a 1 mm extruder.

“Printing elastomers is clearly one of the biggest challenges in the FDM AM industry, so we are proud to have found an industrial-grade solution,” says BigRep Chief Technology Officer Moshe Aknin.

“In terms of applications with Pro Flex, we see high potential for 3D printing in fields like footwear, custom vibration dampers, and seals, due to its high chemical resistance.”

Potential Applications for BigRep Pro Flex Filament

In terms of physical properties, Pro Flex has high temperature resistance and low temperature impact resistance. BigRap claims their new material is durable, has excellent damping behavior and dynamic properties, and will enable companies to explore a broader range of manufacturing opportunities.

For the automotive industry, for example, it can be used for prototyping for gear knobs, door handles, cable sheathing and more. The sporting goods industry is another industry that could benefit, where Pro FLEX can be used for prototyping skateboard wheels, sporting shoe shells, ski tips and ends.

In developing their thermoplastic elastomer, which is a Shore 98 A on the Shore Hardness scale, BigRep studied how elastomers behave in their printers’ extruders. They adapted their material evaluation procedure accordingly.

A note of caution, however. BigRep advises that customers must be experienced in handling extrusion of flexible materials. This is because achieve consistent results can be more challenging than standard filaments.

To this end, BigRep plans to provide a guidance document to all Pro Flex customers. And as part of the BigRep 360-degree service, customer service technicians are also on hand to assist where necessary.

The new Pro Flex filament is available to buy now from the BigRep online store; a 2 kg spool will retail for 98.90 euros plus VAT.

Source: Press Release

Website: LINK