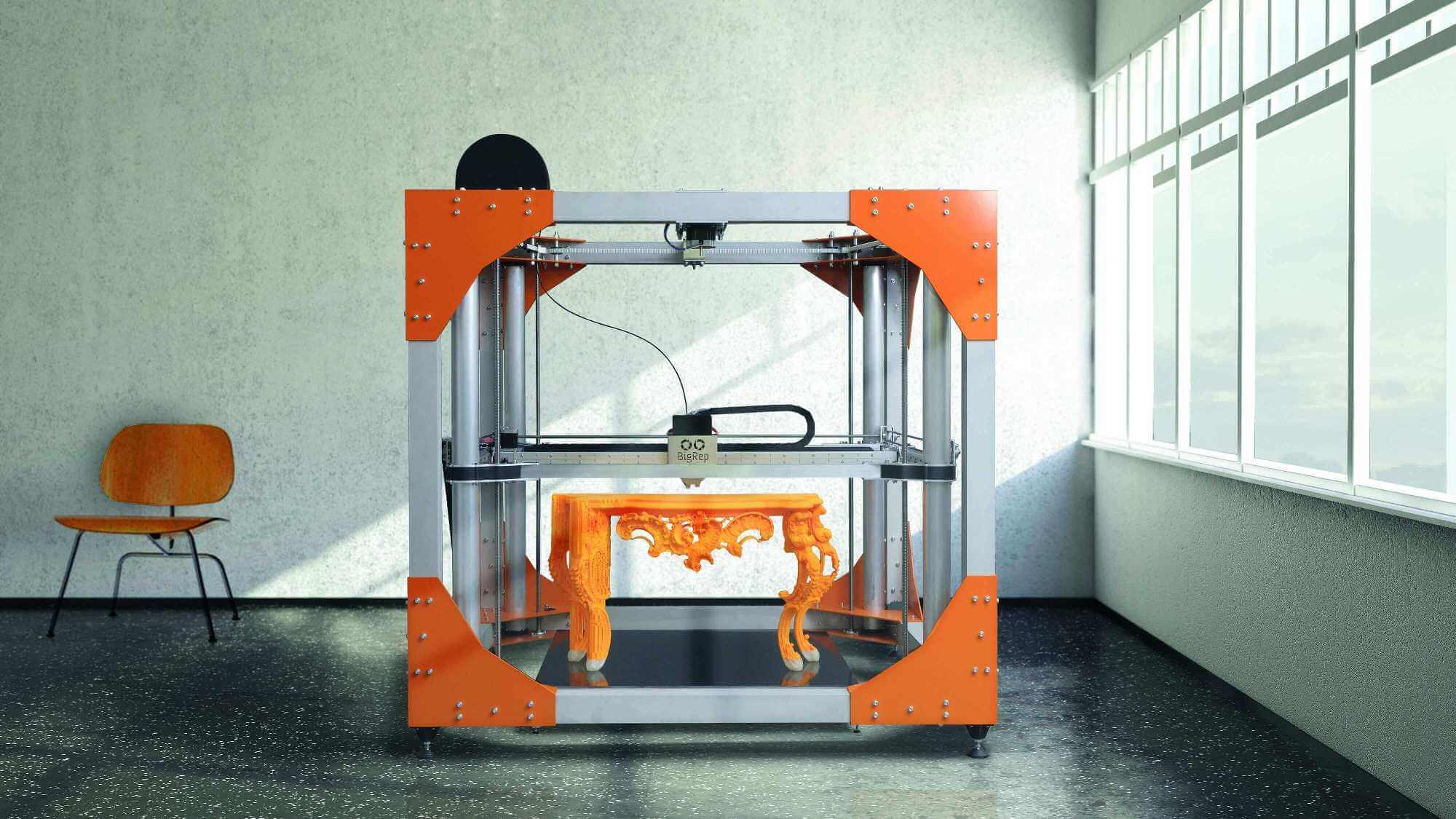

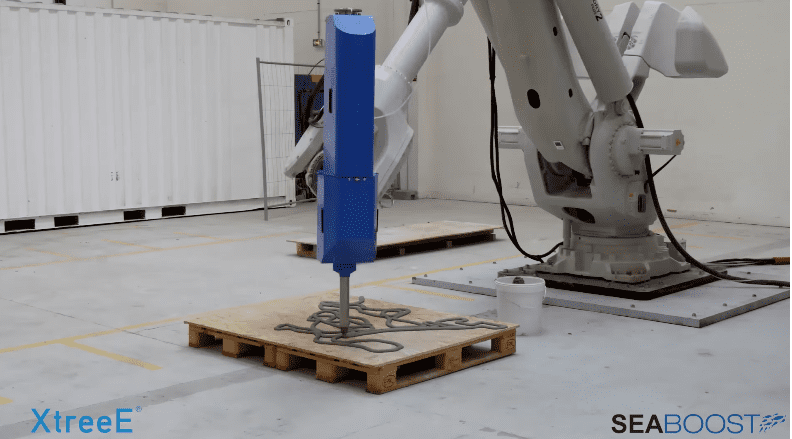

The development could be a significant boost for on-site 3D organ printing at hospitals and research facilities.

3D organ printing has just been given a significant boost thanks an Artificial Intelligence (AI) powered medical imaging software developed by Aether.

The new software powers automatic segmentation of organs and tissues. It further assists in easy converting of single or multi-material printable 3D files.

To test the new software, the company announced a collaboration with Jang Laboratory at Harvard Medical School, US. Clinicians at the school will be able to help feedback and develop the software for public release.

“It’s great that we can say Aether 1 is the only all-in-one 3D bioprinter with the multi-tool capabilities and automation required for organ printing. the truth is a big piece was still missing from the puzzle,” explained Ryan Franks, CEO at Aether.

“Once we learned AI is the only way bioprinting can reach its full potential, we software that would bridge the gap between science-fiction and reality. Aether’s medical imaging AI will be a quantum leap forward. [We] can’t wait to get this software out there and experience the impact it has on the medical field.”

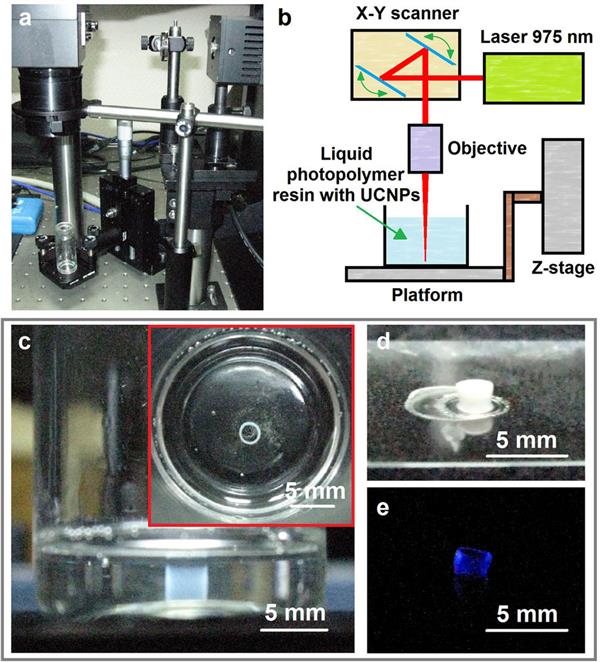

The Automatic Segmentation and Reconstruction (“ASAR”) process provides deep learning models. These can be combined with AI and image processing techniques. Meanwhile, ASAR lets users segment organs and tissues. Researchers can then reconstruct them as digital 3D models before using them for fabrication or other applications.

The full process is automated and does not require any human intervention at all.

Additionally, the advantage of ASAR is that it reduces the time it takes to go from medical image to printable organ.

Aether adds that it has now successfully segmented various organ types with high accuracy across various CT scan datasets. It will try to extend its capabilities toward all organ and tissue types across MRI, X-ray and angiogram technologies.

Printable organs provide an alternative for trainee surgeons and future transplants

3D printed organs offer significant advantages for trainee doctors and surgeons to test their skills on. The more realistic nature of the organs accurately reflects tissue, bone, fat, and blood. This should also help minimize surgical errors.

Aether hopes that hospitals will also be able to 3D print organs on demand for use in transplants. This will help to eliminate waiting lists.

Currently, available imaging software can be confusing and challenging to learn. Aether’s AI medical imaging software challenges this by providing a much simpler interface that is more intuitive to use.

By incorporating AI, the software provides faster speeds of medical image batch processing. In return, this can boost the efficiency of doctors and researchers.

The company adds that its AI 3D bioprinting platform is significantly cheaper to use and therefore provides a great alternative for many hospitals that have organ fabrication systems on-site.

For its collaboration with the Jang Laboratory, Aether will provide a bioprinter, AI, and bio-inks as part of an integrated system to deliver organ printing at site.

The partnership will help train Aether’s AI models and guide future software developments.

Dr. Hae Lin Jang said:

“I am excited to participate in the development of an integrated organ printing system and am looking forward to seeing how a multi-tool bioprinter with AI can enhance our research. I believe this is a revolutionary platform, and hope my advisory role will help Aether empower the worldwide research community.”

3D bioprinting software by Aether. (Image: Aether)

Source: Press Release

Website: LINK

![[FLASH DEAL] Print More Bendy Things – SainSmart TPU Filament 1.75mm 0.8KG Spools, 20% Off](https://www.blogdot.tv/wp-content/uploads/2018/04/flash-deal-print-more-bendy-things-sainsmart-tpu-filament-1-75mm-0-8kg-spools-20-off.jpg)

![[FLASH DEAL] Keep on Printing for Less – 1KG Dikale PLA Filament down to $11.24](https://www.blogdot.tv/wp-content/uploads/2018/04/flash-deal-keep-on-printing-for-less-1kg-dikale-pla-filament-down-to-11-24.jpg)

![[DEAL] Print Squishy Things with this NinjaFlex Clearance Stock at E3D](https://www.blogdot.tv/wp-content/uploads/2018/04/deal-print-squishy-things-with-this-ninjaflex-clearance-stock-at-e3d.jpg)

![[DEAL] Remedy Your 3D Printing War Wounds with this 100-Piece First Aid Kit](https://www.blogdot.tv/wp-content/uploads/2018/04/deal-remedy-your-3d-printing-war-wounds-with-this-100-piece-first-aid-kit.jpg)