NASA’s Johnson Space Center this week awarded Made In Space, the space manufacturing company, with the Small Business Prime Contractor of the Year Award for performing well on every NASA contract.

Made In Space is responsible for the Additive Manufacturing Facility which was sent into orbit in March 2016. As a result of their hard work, Made In Space has won the Small Business Prime Contractor of the Year Award from NASA’s Johnson Space Center in Houston, Texas this week.

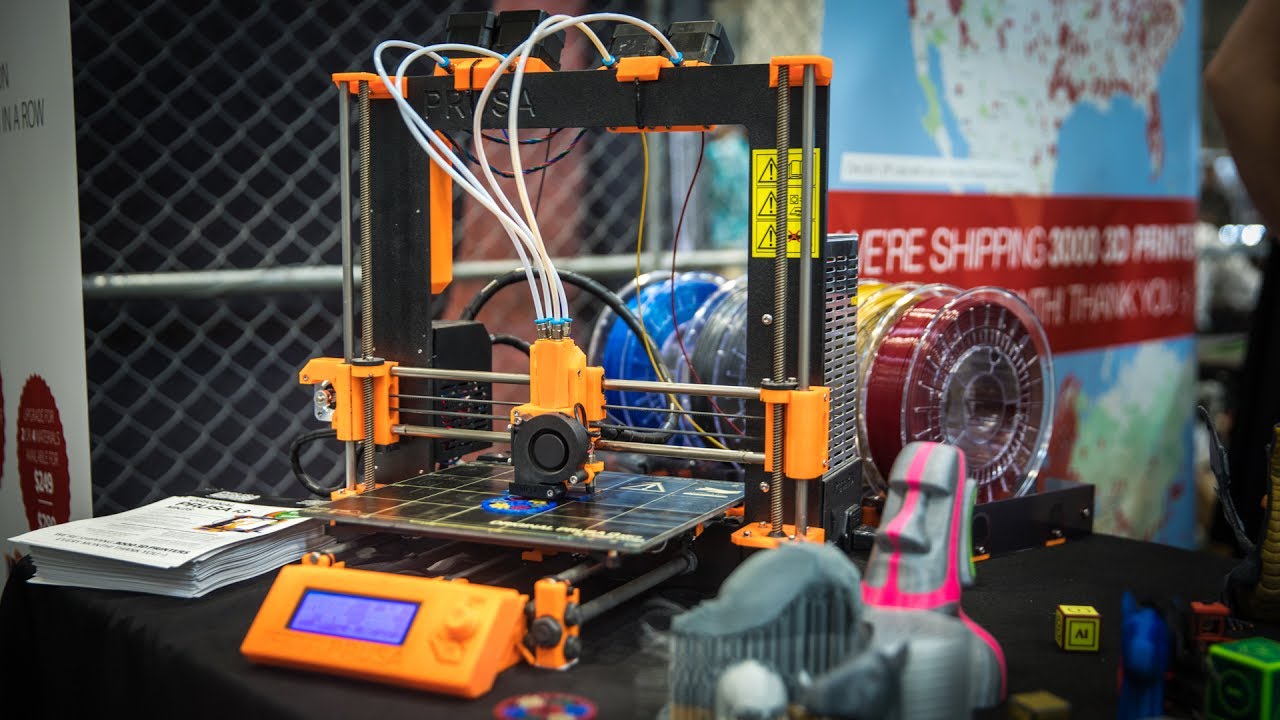

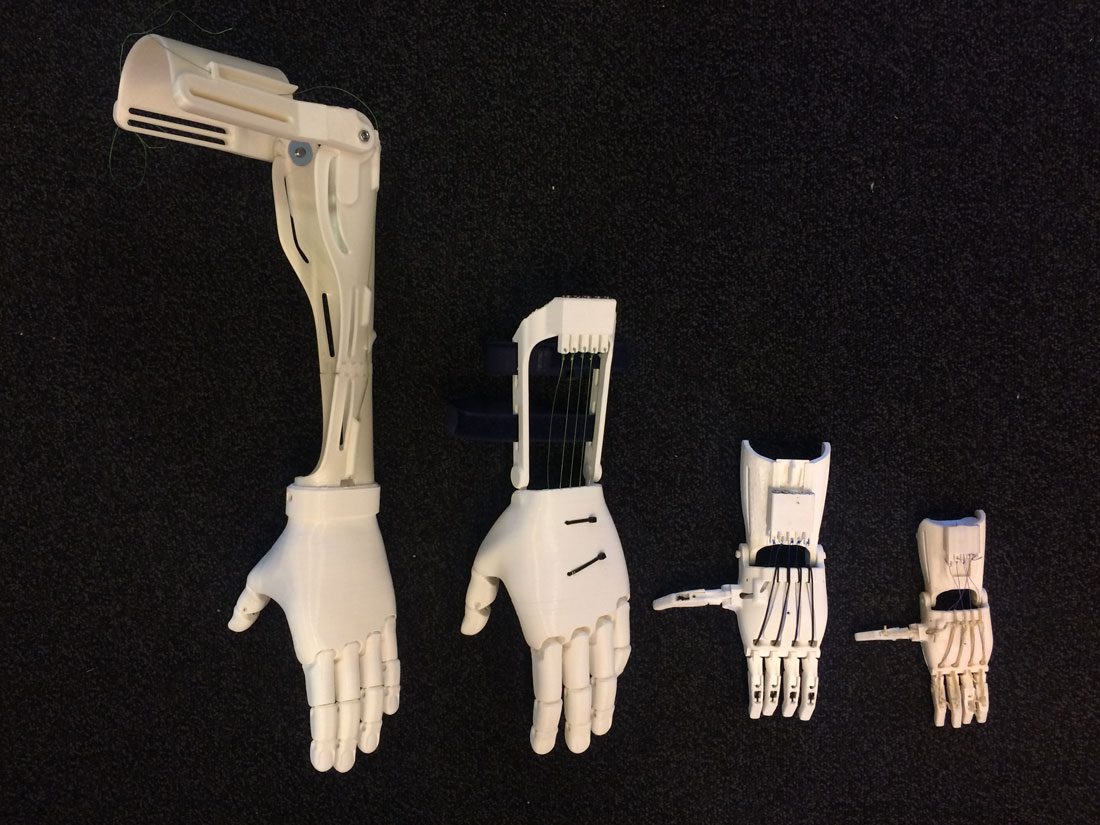

The Additive Manufacturing Facility is a second-generation 3D printing device. Both modular and upgradable, it can be adapted during long missions to new technologies. Now, it has been a permanent fixture aboard NASA’s International Space Station (ISS) for two years.

Although it’s owned by Made In Space, NASA and partners use it. NASA’s Johnson Space Center, which nominated Made In Space, oversees Additive Manufacturing Facility operations.

The Small Business Prime Contractor of the Year Award is given to companies which work cooperatively, are responsive to contractual agreements and perform well on every NASA contract.

“We’re honored to win this prestigious award… We’re grateful for NASA’s confidence in our team and look forward to success with AMF and other programs for many years to come,” said Mike Snyder, Made In Space co-founder and chief engineer.

Digitally Launching 3D Models into Space

The space manufacturing company state in a press release that the integration and operation of the Additive Manufacturing Facility would not have been possible without ISS crew members and Johnson and Marshall Space Flight Centers’ support.

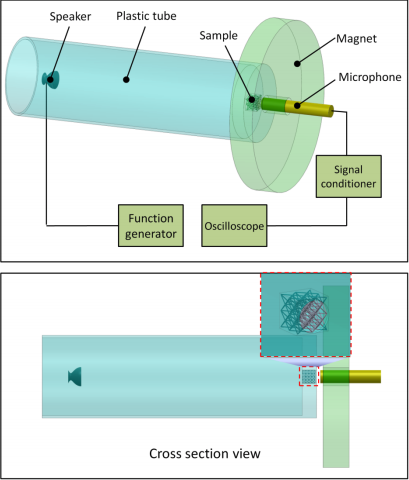

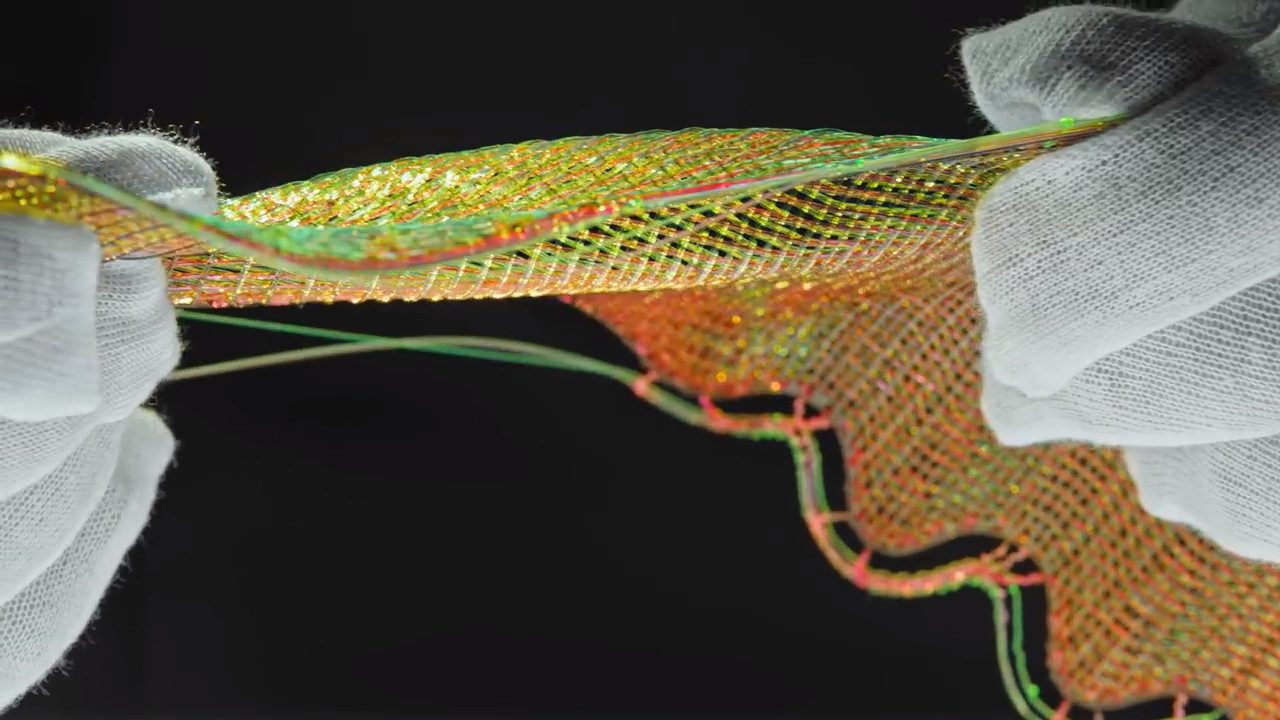

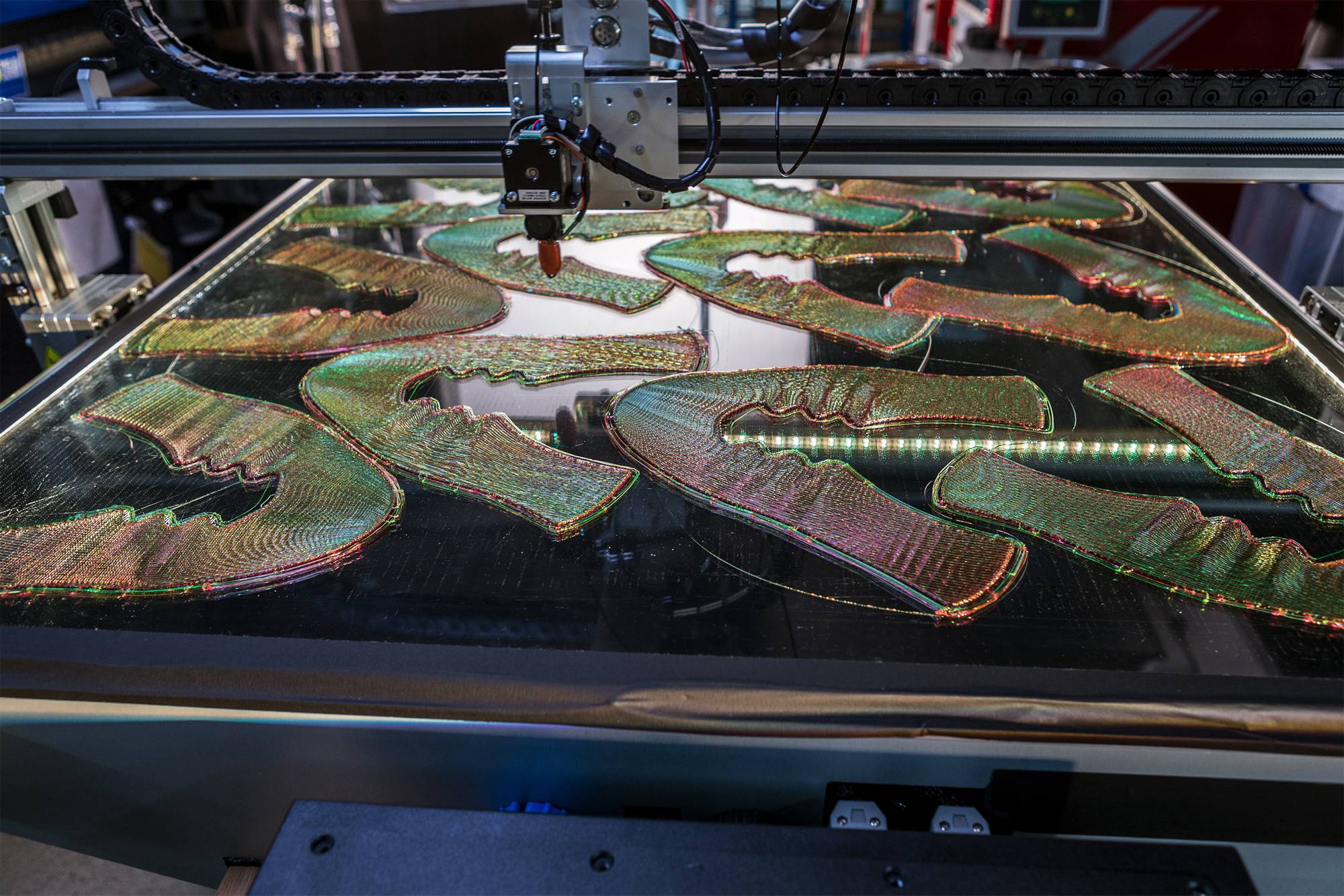

Once a print is created, it is put into the print queue before being “digitally launched” to the printer on ISS. The Additive Manufacturing Facility then prints using multiple feedstock polymers. For example, ULTEM (PEI/PC), ABS and Braskem Green PE.

Impressively, Made In Space has manufactured over 100 parts for government and commercial customers using the Additive Manufacturing Facility which it operates on a weekly basis.

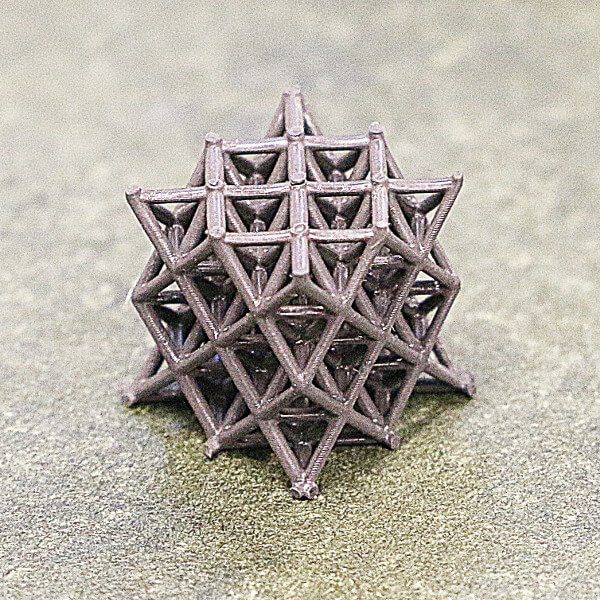

So far, on-orbit manufacturing has resulted in spare parts, complex tools, medical devices and multi-part assemblies. One such print was radiation shields.

Read more about Made In Space on All3DP or visit their website to find out more about their work.

Source: Press Release

Website: LINK

![[DEAL] Pick Up a Lulzbot at 32% Off & Benefit the Free Software Foundation Doing it](https://www.blogdot.tv/wp-content/uploads/2018/04/deal-pick-up-a-lulzbot-at-32-off-benefit-the-free-software-foundation-doing-it.jpg)

![[DEAL] Flagship Printer for Less – Robo R2 3D Printer for $1,250.20](https://www.blogdot.tv/wp-content/uploads/2018/04/deal-flagship-printer-for-less-robo-r2-3d-printer-for-1250-20.jpg)

![[DEAL] Proto-Pasta Polishable Steel PLA, 1.75mm 500g Spools 29% Off](https://www.blogdot.tv/wp-content/uploads/2018/04/deal-proto-pasta-polishable-steel-pla-1-75mm-500g-spools-29-off.jpg)