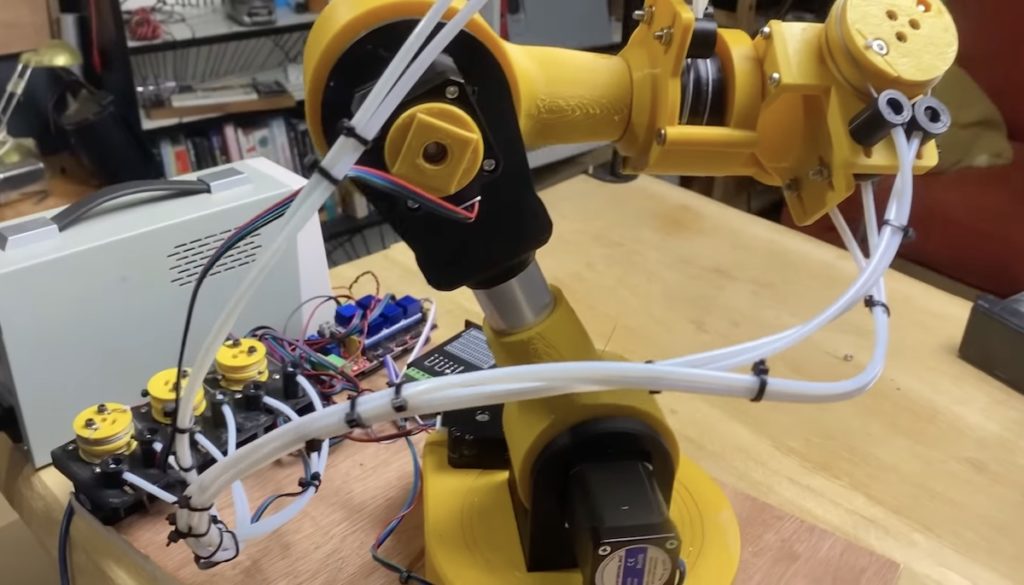

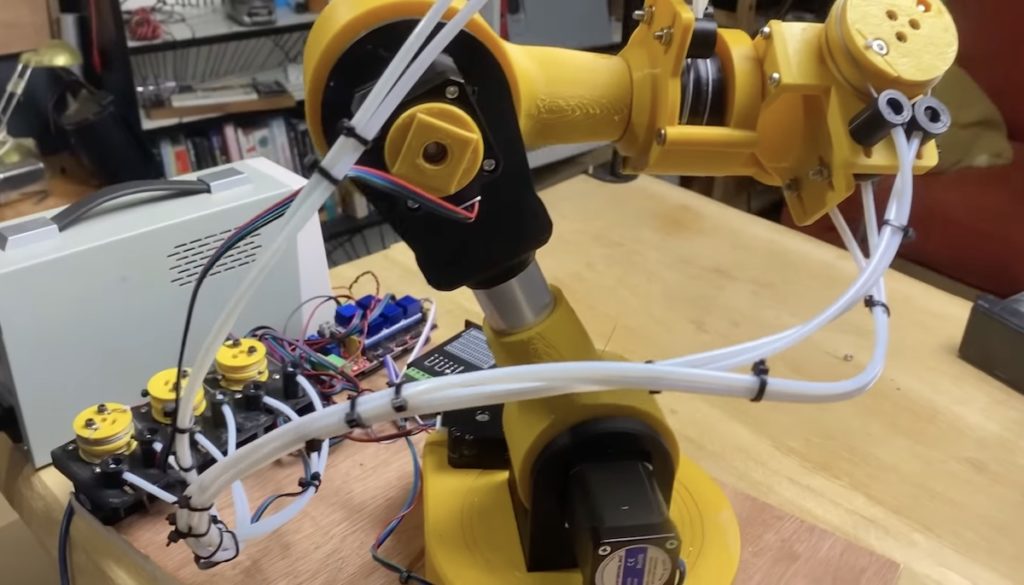

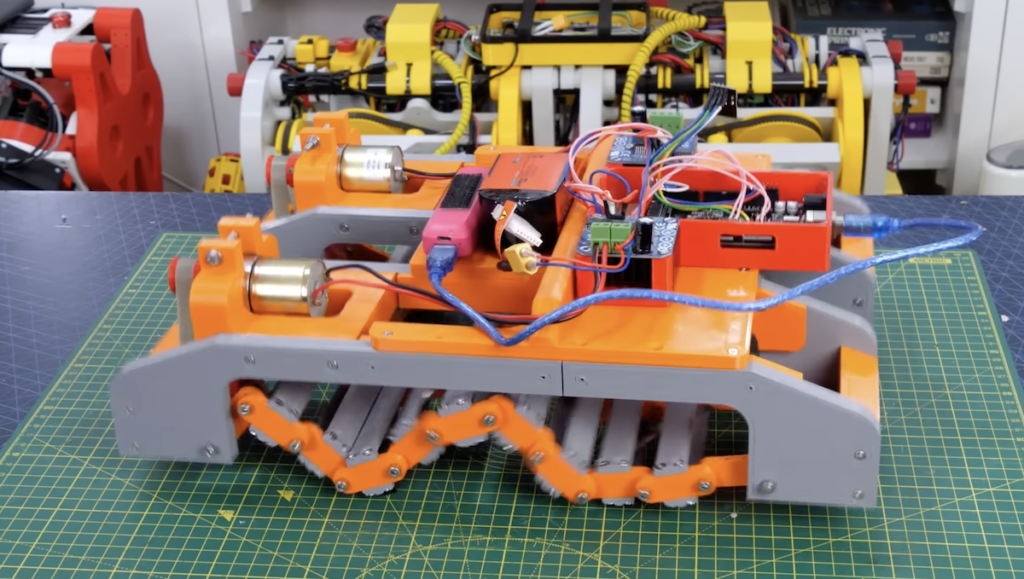

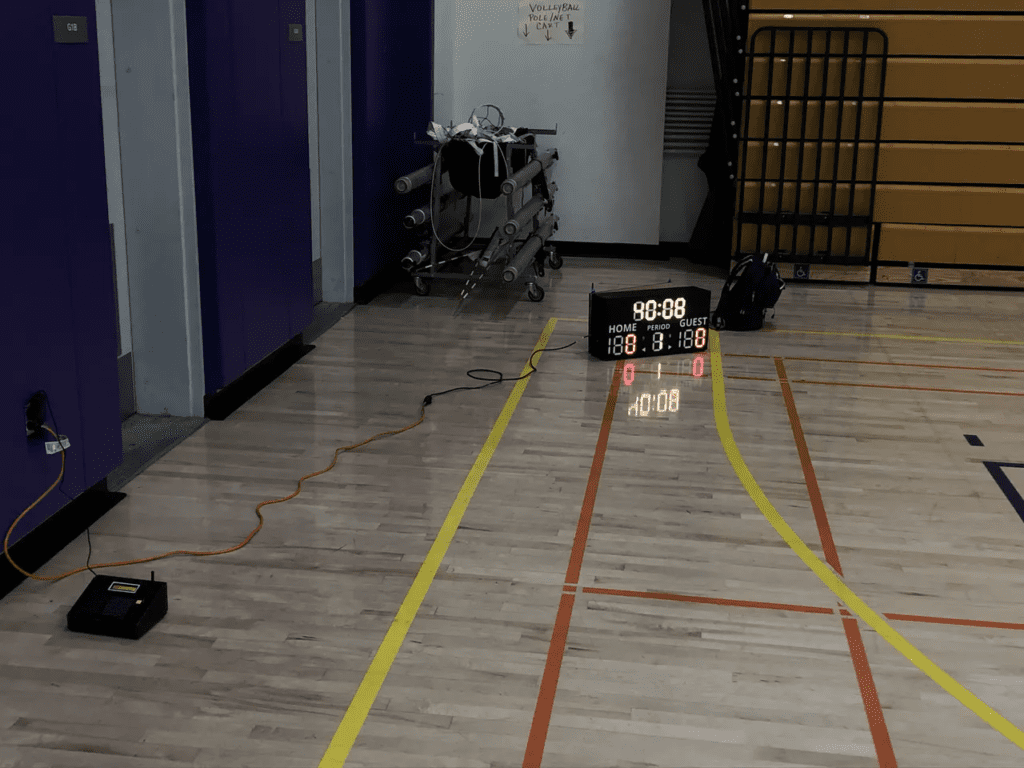

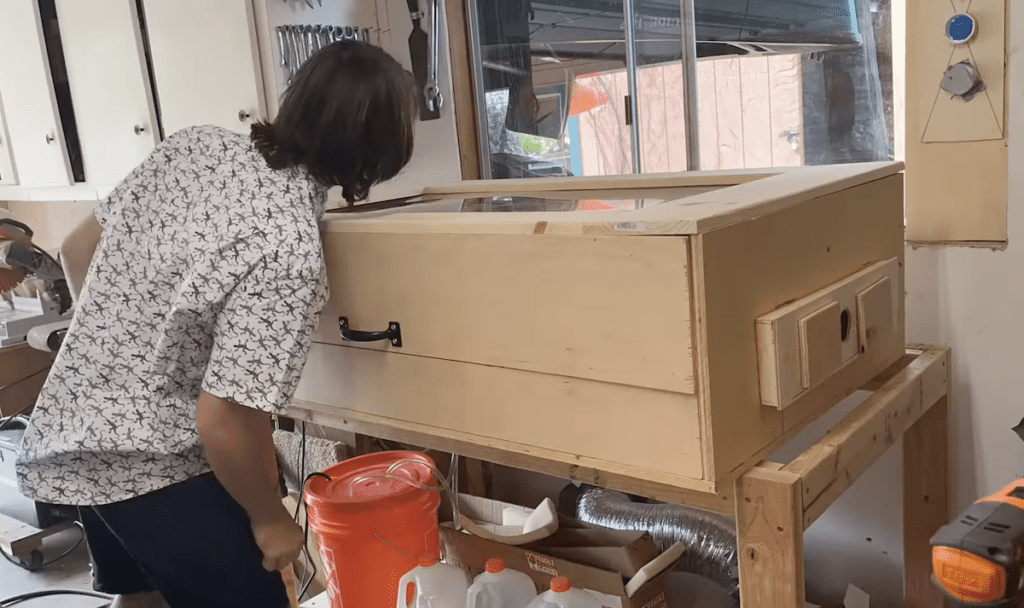

We’re ages past the time when a YouTuber could get away with sloppy camera work. If someone wants to achieve any level of success making videos today, they need near-professional camera equipment. But even that equipment isn’t enough if it’s still used for static shots. Many makers build sliders and other rigs, but James Bruton skipped those small steps and jumped straight to a versatile robotic camera operator.

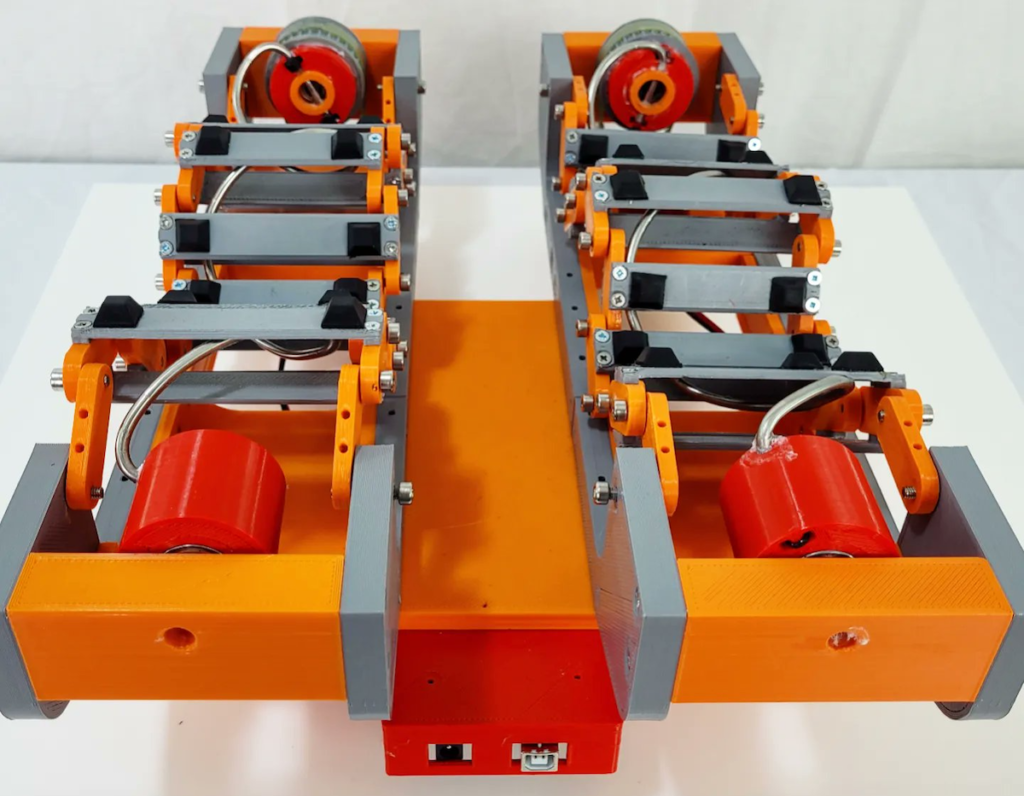

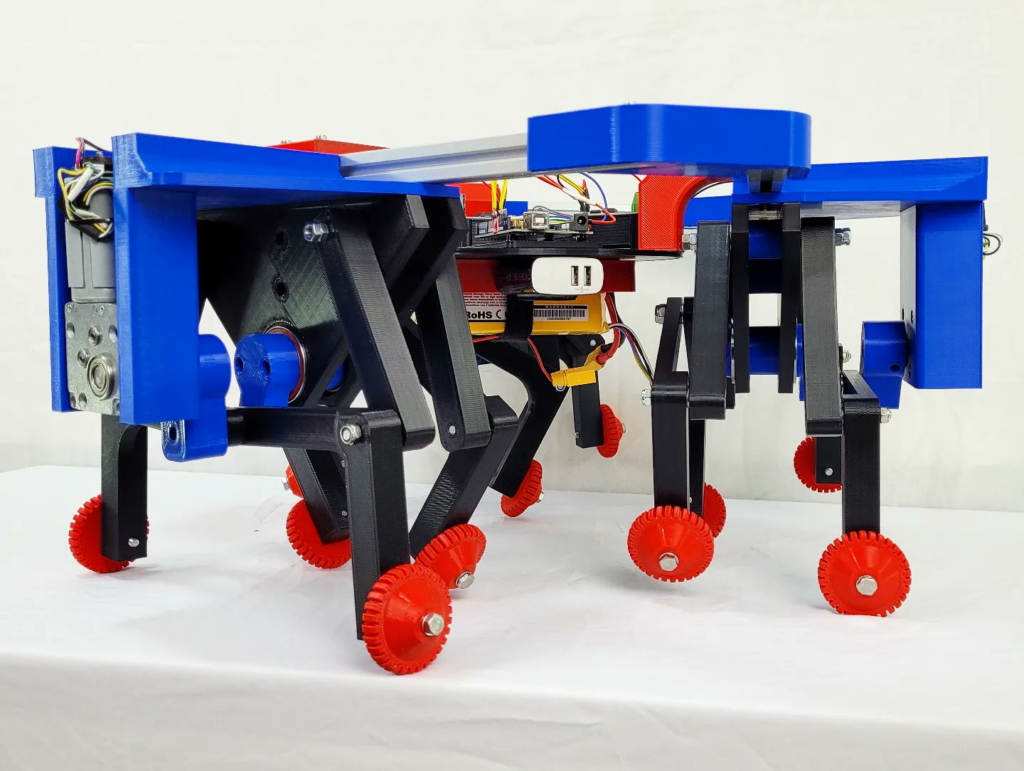

Bruton wanted to capture dynamic videos at any time of day or night without hiring a live-in camera operator and this robot is the result. It can drive around and has complete control over the mounted DSLR camera. It can follow pre-programmed movement patterns, can use tracking to stay focused on Bruton, or a combination of the two to change perspective while staying centered on Bruton. It can also automatically zoom in and out based on motion to ensure that anything interesting is in frame. Bruton can even trigger additional features using foot switches, such as raising a robotic thumbs-up into the frame.

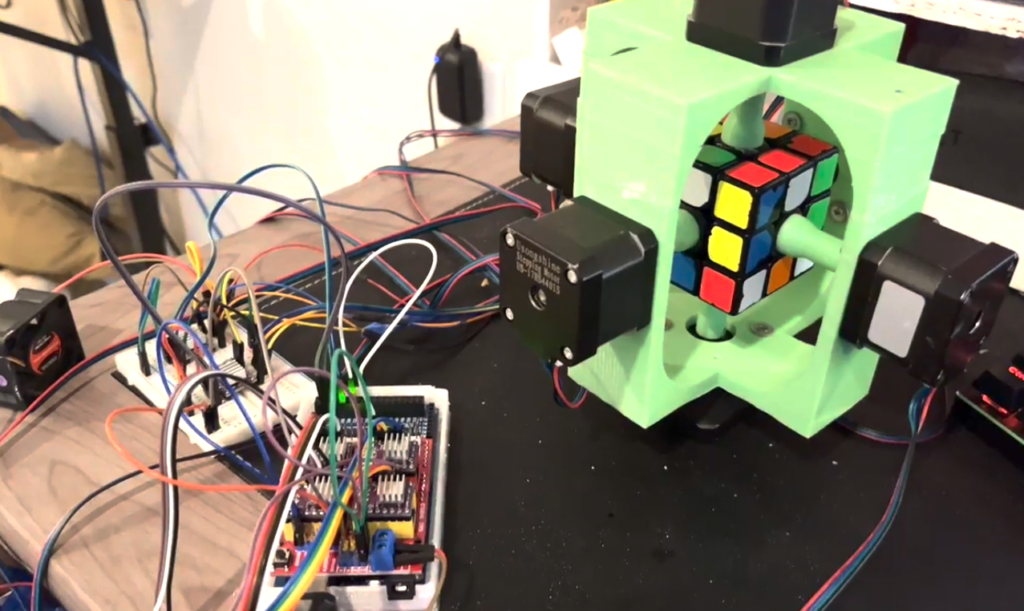

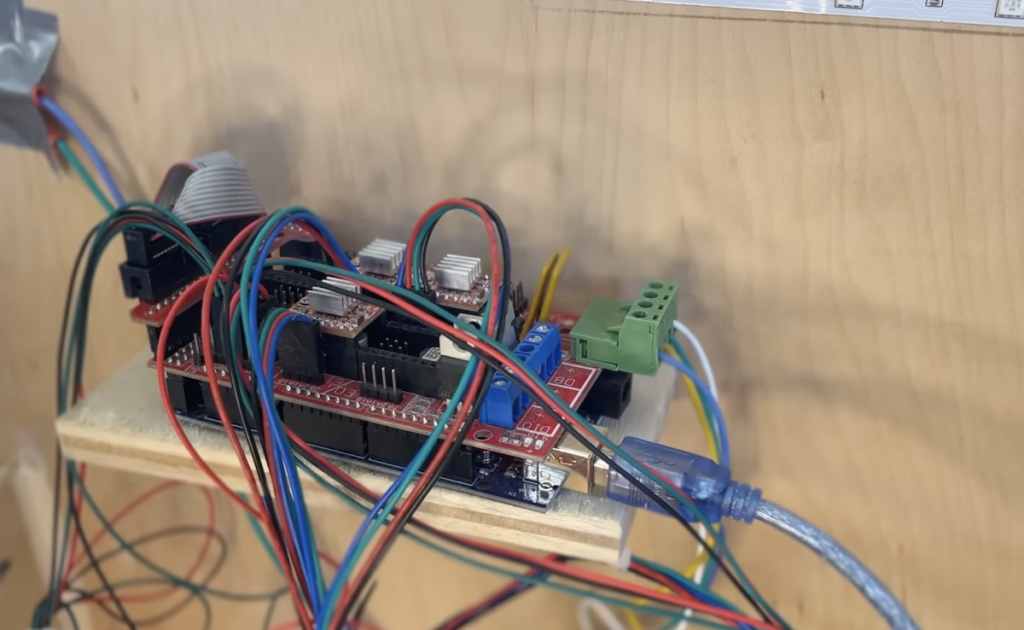

This robot is quite complex and Bruton’s video focuses on features over hardware details, but he does tell us that the robot has both an Arduino Mega 2560 development board and an NVIDIA Jetson Nano single-board computer. The Arduino handles the low-level control of the motors, while the Jetson does the heavy computer vision processing. The robot’s base contains three motor-driven omniwheels, so it can drive smoothly in any direction. The camera mount pans and tilts, and a servo spins the zoom ring. Bruton 3D-printed most of the robot’s physical parts, with only a handful of aluminum extrusion for the vertical structure. With this robot in his arsenal, we expect Bruton’s videos to be far more dynamic in the future

The post Check out James Bruton’s robotic camera operator appeared first on Arduino Blog.

Website: LINK