Schlagwort: CAD

-

VIVE X company, Mindesk, secures $900k to bring CAD designers into Virtual Reality

Reading Time: 5 minutesFollowing the graduation from VIVE X, HTC VIVE’s global VR/AR accelerator, Mindesk has moved its HQ to San Francisco and will continue to develop VR software in Italy and the US. The company secured $900k seed round from HTC VIVE, Barcamper Ventures, A11 Venture and Invitalia Ventures. “We’re excited to see the…

-

How 3D Scanning Can Optimize Food Packaging

Reading Time: 3 minutesSwiss specialists Bachmann Forming use Artec 3D scanners to digitize handcrafted chocolate bunnies, so they can create custom food packaging. Easter is long gone, and your teeth may feel a little tender after scarfing down all that delicious chocolate. But spare a thought for the elaborate packaging of that confectionery, and the…

-

Canadian Software Company Caboma Promises Mass Customisation of Consumer Products

Reading Time: 3 minutes“The future is custom” according to award-winning software company Caboma. Their software SpecifX allows companies to instantly personalize their products and create bespoke solutions through 3D printing. Founded in Montreal, Canada in 2015 by co-founders Jean-Philippe Carmona, Jonathan Borduas, and Julien Arnaud, Caboma has been honing its software to bring personalized products…

-

Facebook Supports New Format for Interactive 3D Model Uploads

Reading Time: 2 minutesYou can now digitally sculpt a 3D model and upload it straight to Facebook to share with your friends. In addition, Facebook is now offering support for higher-quality glTF 2.0 files. Facebook introduced 3D posts in October last year, enabling users to upload interactive models for their network to enjoy. For next…

-

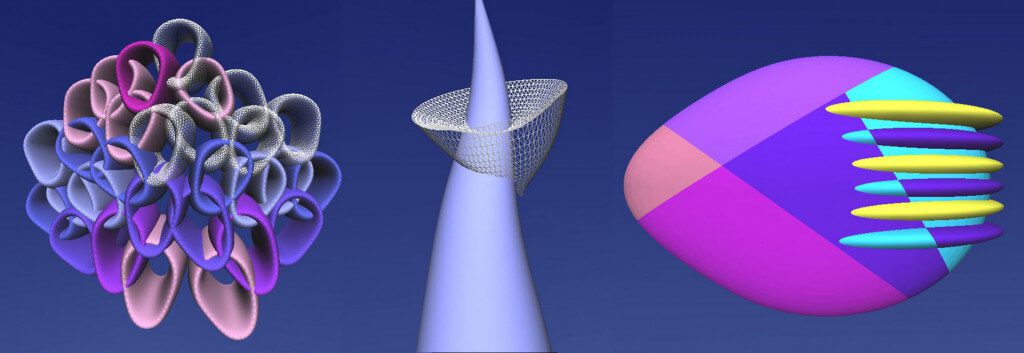

Haptic 3D Modeling Software Anarkik3D Design Version 3.1 is Now Available

Reading Time: 2 minutesAnarkik3D’s latest software for 3D printing, Anarkik3D Design 3.1, enables you to touch and feel 3D qualities of your design using the Falcon mouse system. If you’re a jewelry designer or work in the fashion industry, Anarkik3D has released a new version of 3D design software which is aimed at you. The software…