Schlagwort: bmw

-

MIT and BMW Develop “Liquid Printed Pneumatics” for Inflatable Car Interiors

Reading Time: 3 minutesBMW and MIT’s Self-Assembly Lab have collaborated to develop “liquid printed pneumatics”, the first reported 3D printed inflatable material that can morph from one state to another and expand into any shape or function. Just around two years ago, the BMW Design Department and MIT’s Self-Assembly Laboratory began a cross-disciplinary study with the mutual…

-

MIT and BMW Develop “Liquid Printed Pneumatics” for Inflatable Car Interiors

Reading Time: 3 minutesBMW and MIT’s Self-Assembly Lab have collaborated to develop “liquid printed pneumatics”, the first reported 3D printed inflatable material that can morph from one state to another and expand into any shape or function. Just around two years ago, the BMW Design Department and MIT’s Self-Assembly Laboratory began a cross-disciplinary study with the mutual…

-

BMW Mini Commemorates Royal Wedding with Unique Car Design

Reading Time: 3 minutesBMW has created a special-edition Mini to celebrate the royal wedding of Prince Harry and Megan Markle. Boasting a hand-made graphic print and 3D printed details, the car will be auctioned off for charity. What could be more British than a royal wedding? A one-of-a-kind Mini Cooper S with a bold graphic…

-

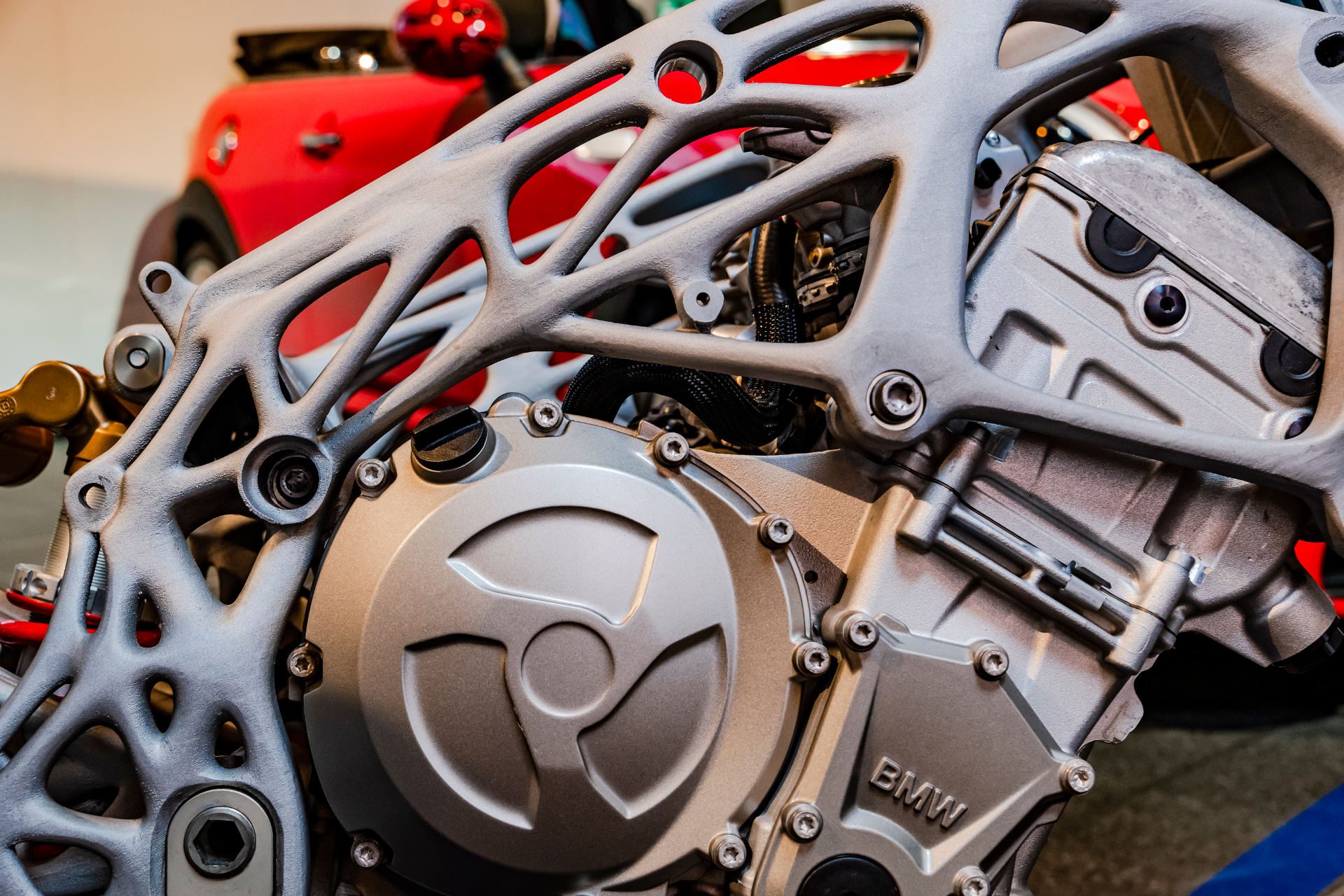

BMW to Establish Additive Manufacturing Campus in Munich

Reading Time: 4 minutesWith a total investment worth over €10 million, automotive giant BMW will open an industrial scale 3D printing campus in Munich, Germany in early 2019. The BMW Group is investing more than €10 million in a new Additive Manufacturing Campus. Located in Oberschleissheim, just north of Munich, the facility will ensure the…

-

MINI Launches 3D Printing Service to Offer Customized Car Accessories

Reading Time: 3 minutesThe automotive company MINI has launched MINI Yours Customised, a new 3D printing service that will allow customers to design custom interior and exterior trim pieces and have them 3D printed for their car. Many people believe that cars, much like dogs, tend to reflect the personality of the owner. The bubbly and…

-

BMW i3 RINSPEED BUDII, selfdriving Media Centre Car!

Reading Time: 2 minutes[mbYTPlayer url=“https://www.youtube.com/watch?v=XAGW1txUV2I“ opacity=“.5″ quality=“medium“ ratio=“auto“ isinline=“false“ showcontrols=“false“ realfullscreen=“true“ printurl=“true“ autoplay=“true“ mute=“true“ loop=“true“ addraster=“true“ stopmovieonblur=“false“ gaTrack=“false“] If you’ve always wanted a self-driving electric car loaded with the latest gadgets, Rinspeed’s Budii, based on the BMW i3, should be on your shortlist. Everything you see inside and outside is controlled via smartphone. Should…

-

Artist Transforms Cars Into These Stunning Animal Sculptures!

Reading Time: 2 minutesBrighton, UK-based artist Ptolemy Elrington has been transforming old car hubcaps into amazing animal sculptures for the past twelve years. He forms the plastic into everything from the eagle you see above to fishes, sharks and even a dragon. Elrington says, „I like to work with reclaimed materials to show that what…