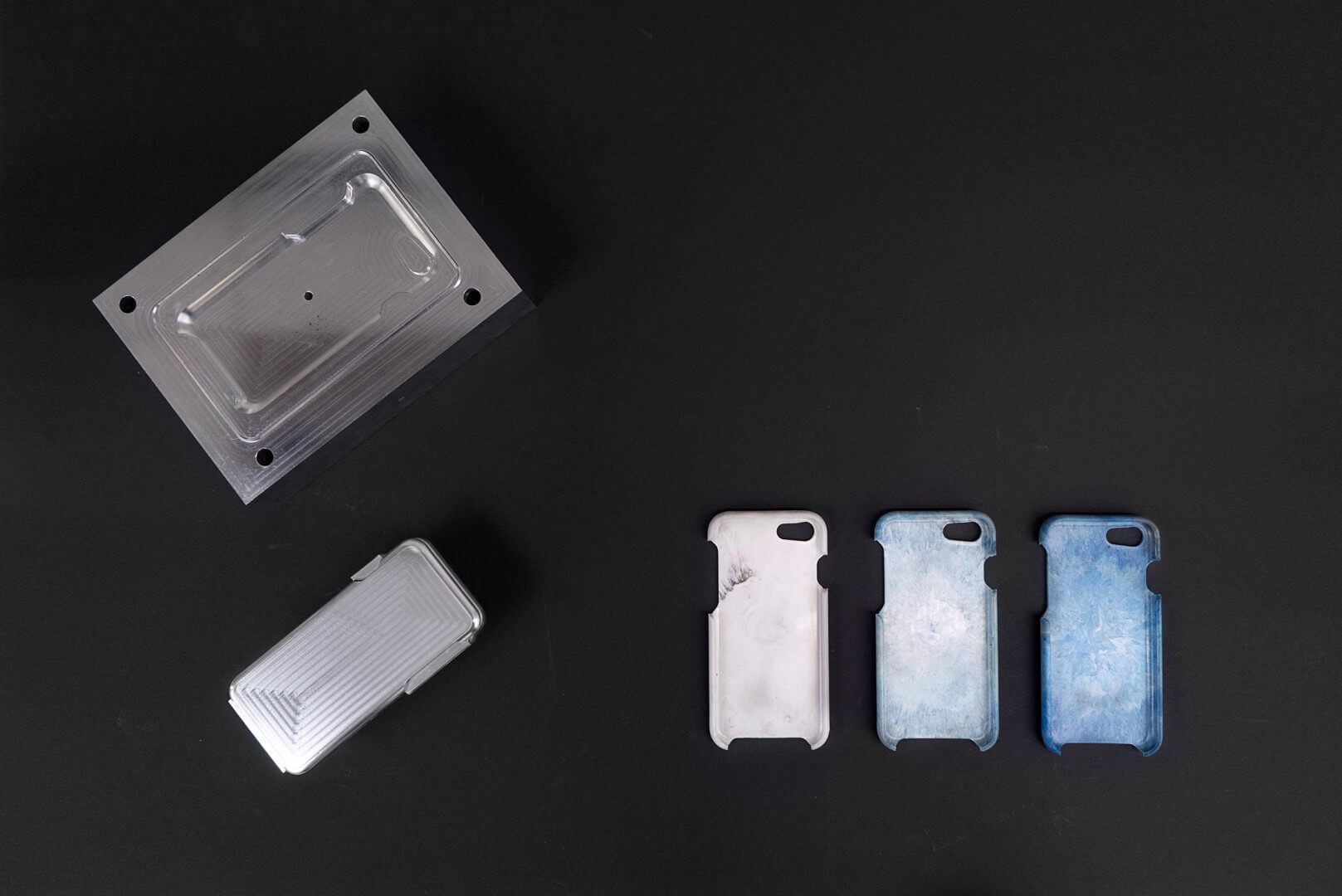

The global community Precious Plastic has created a recycled iPhone case with CNC milling from 3D Hubs. The organization has created an open source production ecosystem that includes a plastic waste shredder, an filament extrusion machine, an injection molder, and a compressor to help process the molds.

The mass production of plastic has led to the rapid accumulation of 8.3 billion metric tons of plastic waste. A whopping 91% of plastics are not being recycled, and this is generating an alarming amount of pollution across the planet.

Launched by Dave Hakkens in 2013, Precious Plastic is a global community of creators and environmentally conscious people looking to end plastic pollution. Anyone is welcome to join and share collaborative techniques and ideas. Thanks to the initiate, there are already hundreds of places globally where people can hand in old plastics to be turned into creative or useful products.

Currently, the team is turning otherwise unrecyclable plastic into functional smartphone cases. Anything from old plastic bottles to takeaway cup tops are being combined to create new iPhone cases.

Plastics tend to be very durable, which makes them a burden to the environment due to the unforgiving breakdown processes. However, at the same time, this burdening quality also enables designers to create new functional projects for everyday use.

Even more exciting, Precious Plastic has created a manufacturing ecosystem to help people to turn plastic waste into valuable products. We previously covered the project during the initial launch of its open source production platform.

The company offers a bundle of machinery, including a plastic waste shredder, an extrusion machine to create 3D printing filaments from recycled plastics, an injection molder, as well as a compressor to help process the molds.

In order to demonstrate the potential of its plastic recycling mission, the company has created a recycled iPhone case. They used a mixture of old milk bottles, takeaway coffee tops, and old cleaning bottles to create this unique, eco-friendly product.

Turning Plastic Waste Into a Polished Product

The mold for the case was created using CNC machining from 3D Hubs. Recently considered a leading 3D printing service hub provider, 3D Hubs recently announced that it would transition into a broader manufacturing service.

Jerry De Vos, who designed the iPhone case, based the mold creation on a CAD file of an iPhone. He could have used metal 3D printing to create the molds, but CNC machining proved to be the better alternative in this case, offering a lower cost and greater accessibility.

This more traditional manufacturing method also offered a high dimensional accuracy (-/-.127mm), while the available materials were able to withstand the heat/pressure of 100’s of shots. The mold cost Precious Plastic €450. The case was finished off using Precious Plastic’s home-made injection molding machine.

Although the team at Precious Plastic admits that iPhone itself isn’t the most environmentally friendly objects, the design ultimately showcases the potential of creating products from recyclable plastics.

The Precious Plastic website features many more innovative and stunning community creations. As the world deals the rising predicament of plastic pollution, this community is fighting to clean up the Earth, while turning waste into practical products.

Source: Precious Plastic & 3DHubs

Website: LINK

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.