Kategorie: Science

-

MIT and BMW Develop “Liquid Printed Pneumatics” for Inflatable Car Interiors

Reading Time: 3 minutesBMW and MIT’s Self-Assembly Lab have collaborated to develop “liquid printed pneumatics”, the first reported 3D printed inflatable material that can morph from one state to another and expand into any shape or function. Just around two years ago, the BMW Design Department and MIT’s Self-Assembly Laboratory began a cross-disciplinary study with the mutual…

-

MIT and BMW Develop “Liquid Printed Pneumatics” for Inflatable Car Interiors

Reading Time: 3 minutesBMW and MIT’s Self-Assembly Lab have collaborated to develop “liquid printed pneumatics”, the first reported 3D printed inflatable material that can morph from one state to another and expand into any shape or function. Just around two years ago, the BMW Design Department and MIT’s Self-Assembly Laboratory began a cross-disciplinary study with the mutual…

-

Printrbot Unveils New 3D Printers & CNC Milling Kit at Maker Faire 2018

Reading Time: 4 minutesAt the recently held Maker Faire 2018 event, the veteran 3D printer manufacturer Printrbot unveiled a range of new products, including the new Printrbot Play v2, a unique conveyor belt-style 3D printer kit for long prints and rapid single-object reproduction, as well as the Printrbot CNC v2 KIT. The desktop 3D printing…

-

Printrbot Unveils New 3D Printers & CNC Milling Kit at Maker Faire 2018

Reading Time: 4 minutesAt the recently held Maker Faire 2018 event, the veteran 3D printer manufacturer Printrbot unveiled a range of new products, including the new Printrbot Play v2, a unique conveyor belt-style 3D printer kit for long prints and rapid single-object reproduction, as well as the Printrbot CNC v2 KIT. The desktop 3D printing…

-

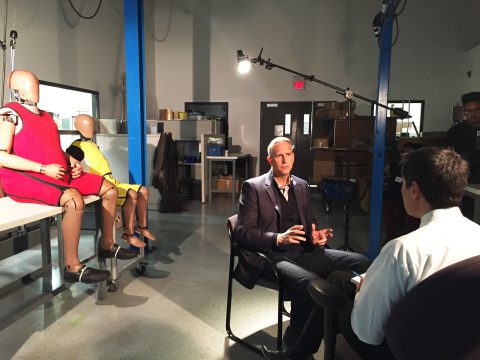

Humanetics is 3D Printing Crash Test Dummies That Resemble Elderly People

Reading Time: 3 minutesThe crash test dummy manufacturer Humanetics is using Markforged’s 3D printing technology and Onyx carbon-composite material to produce dummies the resemble elderly drivers, helping them accurately reflect injuries that could occur in a real car accident. Car crash testing is an integral part of ensuring vehicle safety, and brave human-like dummies have…

-

![[DEAL] 15% Off Nozzles at MatterHackers](data:image/svg+xml;charset=utf-8,%3Csvg xmlns%3D'http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg' viewBox%3D'0 0 1920 1080'%2F%3E)

[DEAL] 15% Off Nozzles at MatterHackers

Reading Time: < 1 minuteMatterHackers is knocking 15% off virtually every nozzle it carries, including the bejeweled Olsson Ruby, E3Ds of every size and other specialty nozzles. As if you needed an excuse to bite the proverbial bullet and stock up on spare nozzles, MatterHackers is giving you one over a hundred. For the time…

-

![[DEAL] 15% Off Nozzles at MatterHackers](data:image/svg+xml;charset=utf-8,%3Csvg xmlns%3D'http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg' viewBox%3D'0 0 1920 1080'%2F%3E)

[DEAL] 15% Off Nozzles at MatterHackers

Reading Time: < 1 minuteMatterHackers is knocking 15% off virtually every nozzle it carries, including the bejeweled Olsson Ruby, E3Ds of every size and other specialty nozzles. As if you needed an excuse to bite the proverbial bullet and stock up on spare nozzles, MatterHackers is giving you one over a hundred. For the time…

-

![[DEAL] 15% Off Nozzles at MatterHackers](data:image/svg+xml;charset=utf-8,%3Csvg xmlns%3D'http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg' viewBox%3D'0 0 1920 1080'%2F%3E)

[DEAL] 15% Off Nozzles at MatterHackers

Reading Time: < 1 minuteMatterHackers is knocking 15% off virtually every nozzle it carries, including the bejeweled Olsson Ruby, E3Ds of every size and other specialty nozzles. As if you needed an excuse to bite the proverbial bullet and stock up on spare nozzles, MatterHackers is giving you one over a hundred. For the time…

-

Volkswagen Uses 3D Printing for Pikes Peak Hill Climb Supercar

Reading Time: 3 minutesVolkswagen, the German automotive manufacturing company, has unveiled a purpose built supercar, the I.D. R Pikes Peak electric, to compete in the Pikes Peak International Hill climb in Colorado Springs next month. With only a short time-frame to develop the car, the team used 3D printing extensively to prototype components. The Pikes Peak International Hill…

-

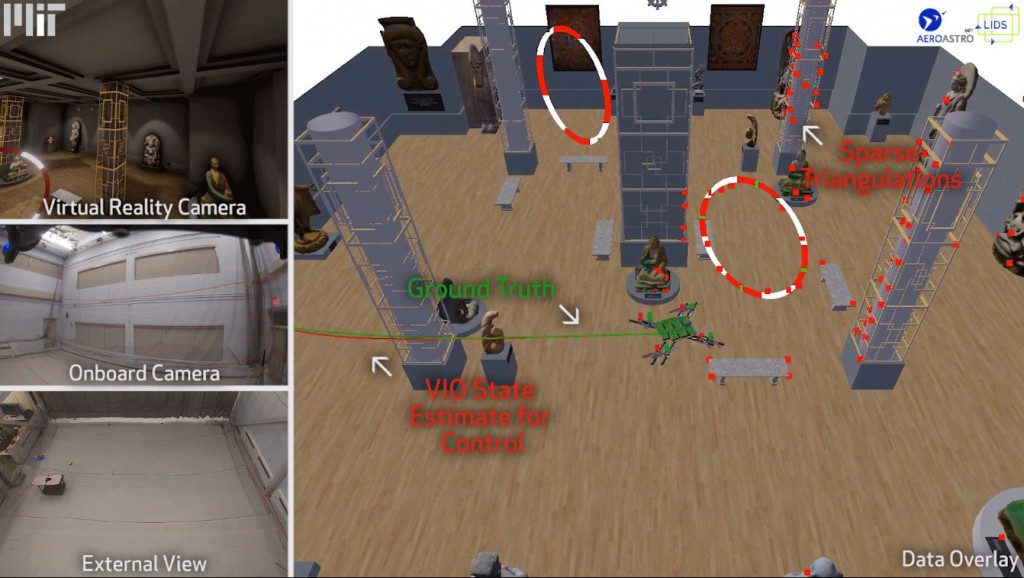

MIT Trains Drones to Fly Using VR “Flight Goggles”

Reading Time: 3 minutesEngineers from MIT have built a virtual reality system for drones which they hope will reduce the frequency that the pilotless aircraft crash during training. The VR training system is called “Flight Goggles”. Training autonomous drones to fly quickly currently means relying on enclosed grounds with a range of physical objects. These objects can…

-

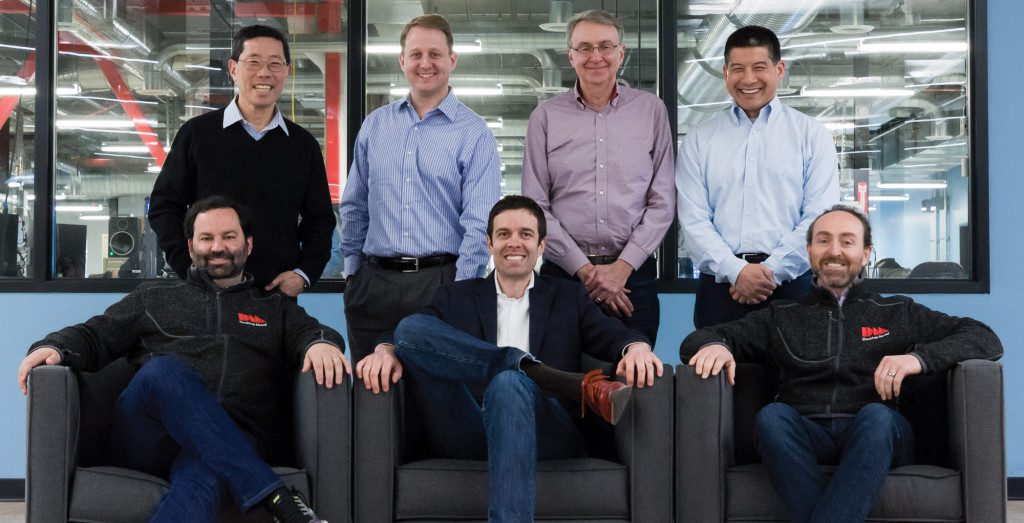

Arevo Boosts Expansion of Carbon Fiber 3D Printing With $12.5 Million Funding Round

Reading Time: 3 minutesThe start-up has launched a unique carbon fiber 3D printing technology that allows for enhanced scalability. Through the latest cash injection, it hopes to commercialize the technology more quickly. Carbon fiber 3D printing is set to become a dominant trend in additive manufacturing over the next few years. This is driven in…

-

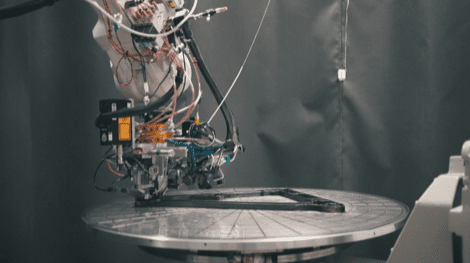

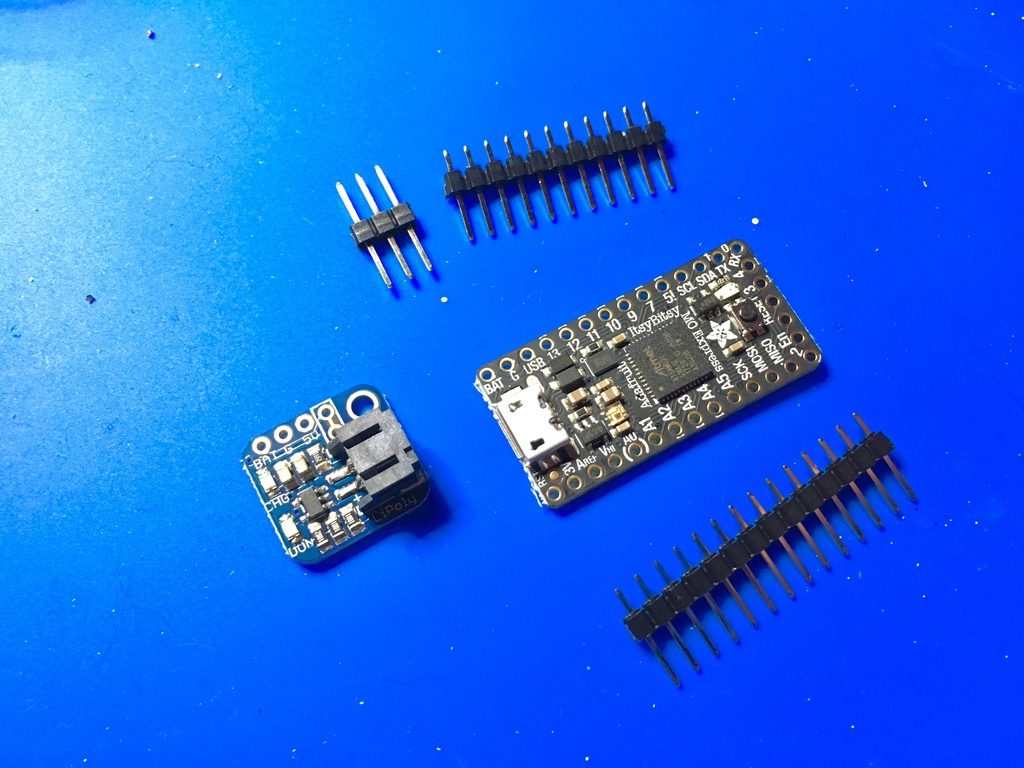

Weekend Project: 3D Printed Motorized Turntable for Photo & Video

Reading Time: 4 minutesWant to capture all 360 degrees of an object with your camera? Adafruit has recently shared a 3D printing project that shows you how to create an inexpensive turntable made for photographers and videographers. As anyone in the photography or film world knows, the many different types of production equipment that are…

-

Weekend Project: 3D Print Your Own Workshop-Ready Steampunk Goggles

Reading Time: 3 minutesMany steampunk cosplay items provide mechanical style and an aesthetic look. But these elaborate 3D printed steampunk goggles are equipped with prescription lenses and welding filters that will keep your eyes safe while you’re in the workshop. Inspired by historical science fiction and steam-powered machinery, the steampunk genre has blossomed into one…

-

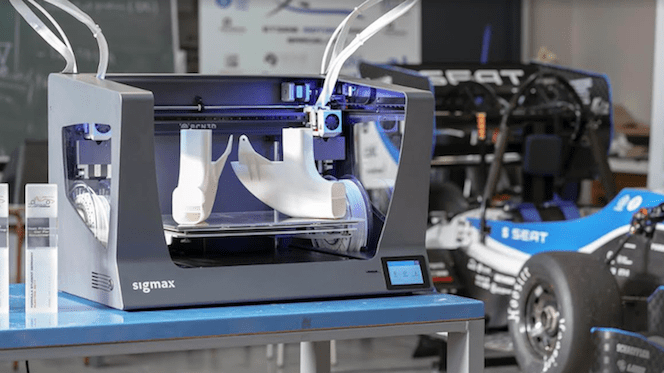

ETSEIB Motorsport Uses BCN3D Sigmax 3D Printer to Develop Racing Car for Formula Student Competition

Reading Time: 3 minutesETSEIB Motorsport, the automotive engineering team from the Polytechnic University of Catalonia, is now using 3D printing from BCN3D to help develop racing car parts for the Formula Student competition. Formula Student is a competition between students from universities worldwide with a focus on excellence in engineering. To enter the competition, teams are required to design,…

-

This 3D Printed Smart Gel Walks Underwater and Moves Objects

Reading Time: 2 minutesEngineers at Rutgers University have created a 3D printed smart gel that walks underwater. It can also grab objects and move them. If you’re looking for some nightmare dreamscape material, try this on for size. Rutgers University researchers have invented a 3D printed smart gel that can walk underwater, grab objects, and…

-

3D Printing Saves Toddler’s Life with Kidney Transplant

Reading Time: 2 minutesIn a pioneering operation, surgeons use 3D scanning and 3D printing to verify that a father’s kidney would fit in his young son’s abdomen before a live-saving kidney transplant. Surgeons at Guy’s and St Thomas’ NHS Foundation Trust in London have used 3D printing to save a two-year-old child’s life in a complex…

-

![[DEAL] Up to 25% Off Monoprice Filament & Electronics](data:image/svg+xml;charset=utf-8,%3Csvg xmlns%3D'http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg' viewBox%3D'0 0 1422 800'%2F%3E)

[DEAL] Up to 25% Off Monoprice Filament & Electronics

Reading Time: 2 minutesAmerican electronics retailer Monoprice is holding a short-term site-wide sale, knocking up to 25% off its wares. Sadly this excludes its 3D printers, but for filament and maker-y projects involving Arduino, Raspberry Pi and others, it can be a useful resource. If you’re in the market to do some project tinkering this…

-

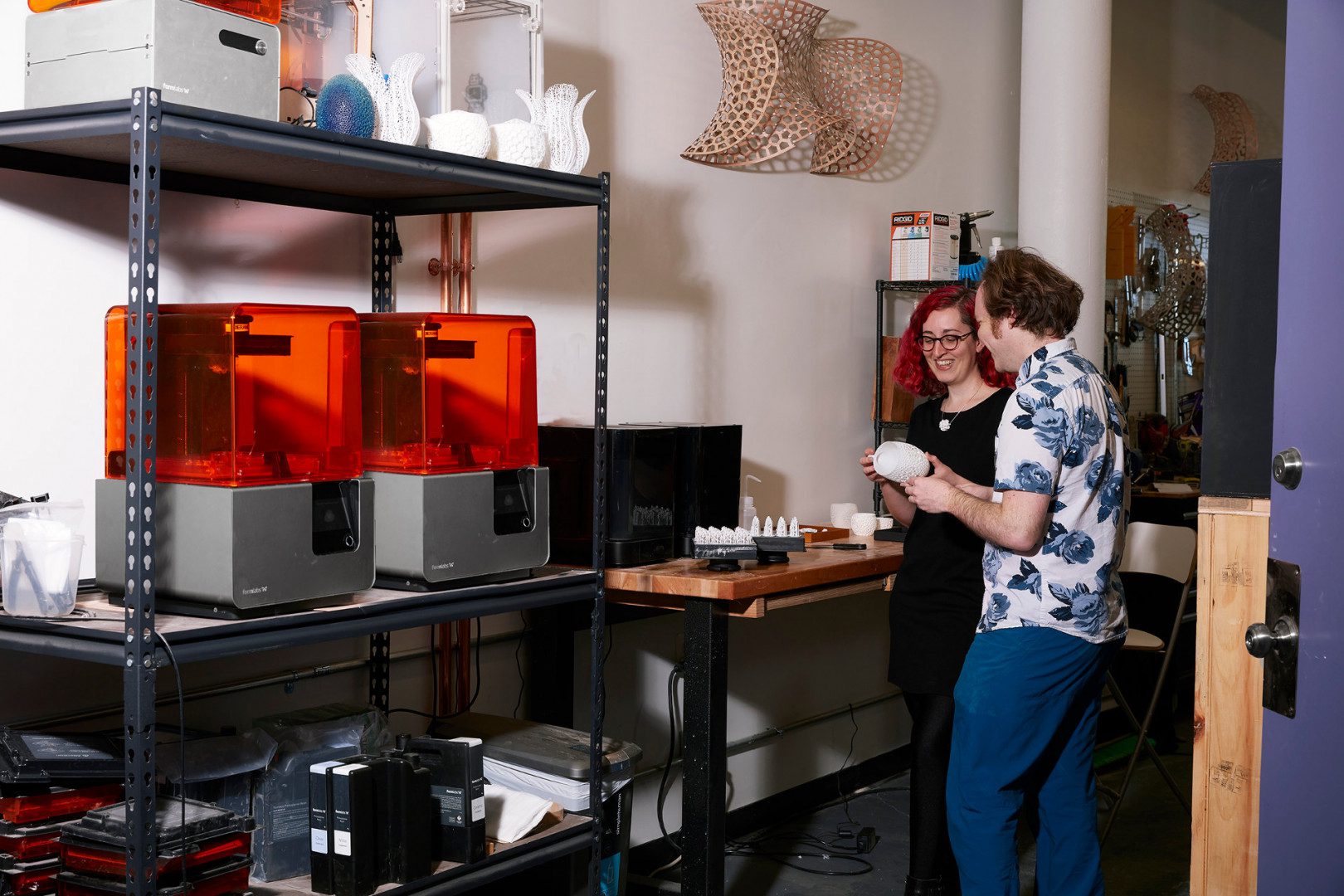

New Ceramic 3D Printed Jewelry from Nervous System

Reading Time: 3 minutesPorifera is a new jewelry collection by Nervous System inspired by the forms of deep-sea glass sponges. It’s 3D printed using an experimental Ceramic Resin from Formlabs. Nervous System is a generative design studio that produces unique collections of art, fashion, jewelry, and housewares. What makes their work so unique? Because it…

-

ESA Now Testing a Prototype Microgravity 3D Printer

Reading Time: 3 minutesThe European Space Agency (ESA) is testing a 3D printer designed to work under microgravity and fabricate with engineering polymers featuring high end mechanical and thermal properties. A prototype 3D printer capable of printing in microgravity has been handed over to the European Space Agency (ESA) for use on the International Space…

-

Microsoft Debuts Xbox Adaptive Controller for Limited-Mobility Gamers

Reading Time: 4 minutesDeveloped at Microsoft’s expansive campus in Redmond, Washington, the Xbox Adaptive Controller is a first of its kind for the company: a hardware peripheral created with an inclusive design approach. In the world of console video gaming, exclusivity is a desirable thing. Exclusive games and studio partnerships give enough differentiation to draw…

-

Project of the Week: 3D Print a Solar-Powered Open RC Boat

Reading Time: 3 minutesWant to spend the summer days sailing the seven seas and soaking up the sun? Thingiverse user UniversalMaker shows us how to build a 3D printed Open RC Boat equipped with solar panels. With summertime approaching and warm weather abound, it’s the perfect time to head over to your local body of…

![[DEAL] 15% Off Nozzles at MatterHackers](https://www.blogdot.tv/wp-content/uploads/2018/05/deal-15-off-nozzles-at-matterhackers.jpg)

![[DEAL] Up to 25% Off Monoprice Filament & Electronics](https://www.blogdot.tv/wp-content/uploads/2018/05/deal-up-to-25-off-monoprice-filament-electronics.jpg)