Shapeways has a new CEO and his name is Gregory Kress; the company will continue its expansion into a 3D printing marketplace where creators can design, make, and sell their ideas.

New York-based 3D printing service and marketplace Shapeways has announced the official appointment of Gregory Kress as CEO. He’ll be taking over from interim CEO Tom Finn, who was overseeing the transition from Co-Founder and former CEO Peter Weijmarshausen since August 2017.

“While excited about how far we’ve come, I look forward to accelerating Shapeways’ vision to become the complete end-to-end platform helping people, ‘design, make, and sell,’ regardless of their 3D modeling experience,” says Kress.

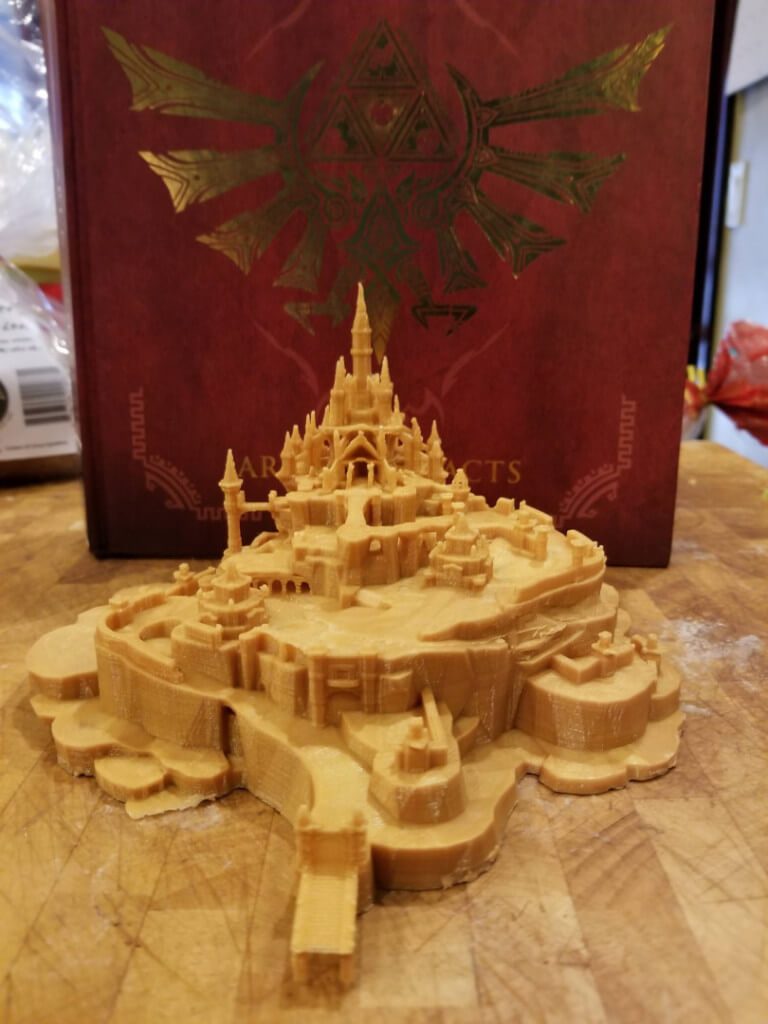

Shapeways began operations in 2007 as an online 3D printing service. It has since evolved into a sophisticated marketplace for the production, distribution, and supply chain fulfillment of 3D printed goods.

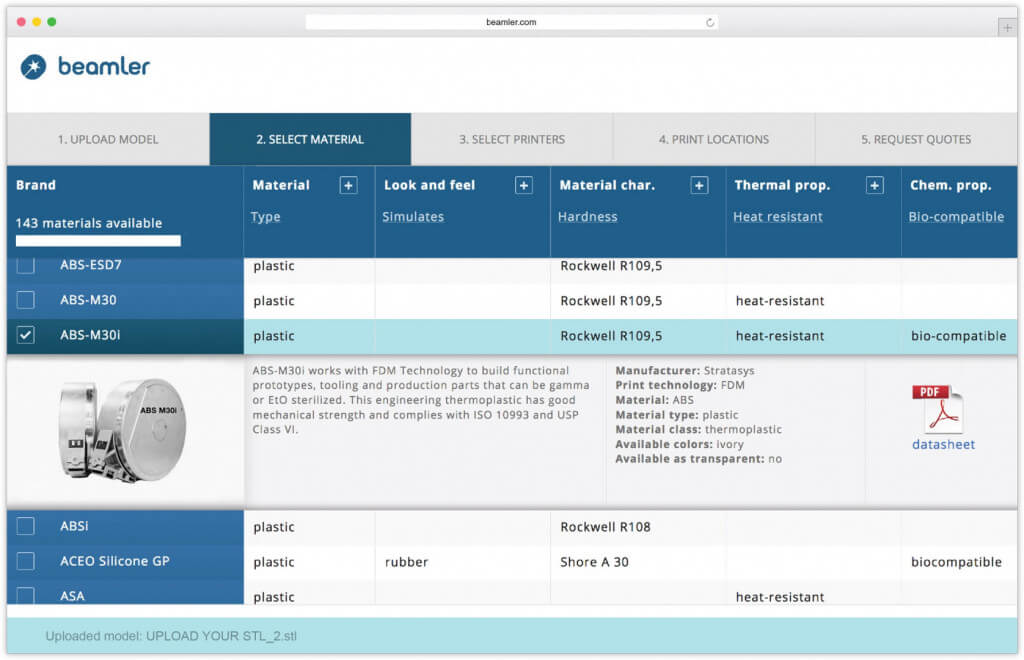

Currently, Shapeways offers over 60 different 3D printing materials and finishes to their customers. They’re closing in on a magic number — their 10 millionth product printed — and receives 140,000 new design uploads each month.

With the hiring of Kress, the company says it has begun a new process; to implement services that will address both creative and business “pain points” for creators. It will expand its end-to-end services for current and new Shapeways users to design, make and sell their work.

Intriguingly, Shapeways says it also plans to expand vertically and provide production services beyond 3D printing. This seems to mirror similar changes in strategy that were recently announced by another leading light of the 3D printing industry, 3D Hubs.

Gregory Kress is the Shape(ways) of Things to Come

According to his corporate bio, Kress brings more than fifteen years of relevant experience to his new role at Shapeways.

He most recently served as President and COO of Open Education. There, Kress oversaw the business expanding to more than 400,000 students in 25 countries and supported by over 1,200 employees. Prior to Open Education, he spent 11 years in leadership positions across GE.

“We know people have ideas or want products that can be made and sold thanks to advanced design, production, and fulfillment technology — but most of them don’t know where to begin. Without proper support or infrastructure, the entire process seems inaccessible, complicated, intimidating, and expensive,” says Albert Wenger, Managing Partner at Union Square Ventures.

“Greg is experienced at growing platform businesses and we’re thrilled that he’ll be applying that deep knowledge and energy to empower creators to realize those design dreams.”

Shapeways has factories and offices in New York, the Netherlands, and partners around the globe. Company investors include Union Square Ventures, Index Ventures, Lux Capital, Andreessen Horowitz, INKEF Capital, Hewlett Packard Ventures, and Presidio Ventures.

Source: Press Release

Website: LINK

![[DEAL] MakerGear M3-SE & M3-ID 3D Printers, $200 Off](https://www.blogdot.tv/wp-content/uploads/2018/02/deal-makergear-m3-se-m3-id-3d-printers-200-off.jpg)

![[DEAL] Sugru Hacks for Your Home Kit, 14% Off at $12.95](https://www.blogdot.tv/wp-content/uploads/2018/02/deal-sugru-hacks-for-your-home-kit-14-off-at-12-95.jpg)