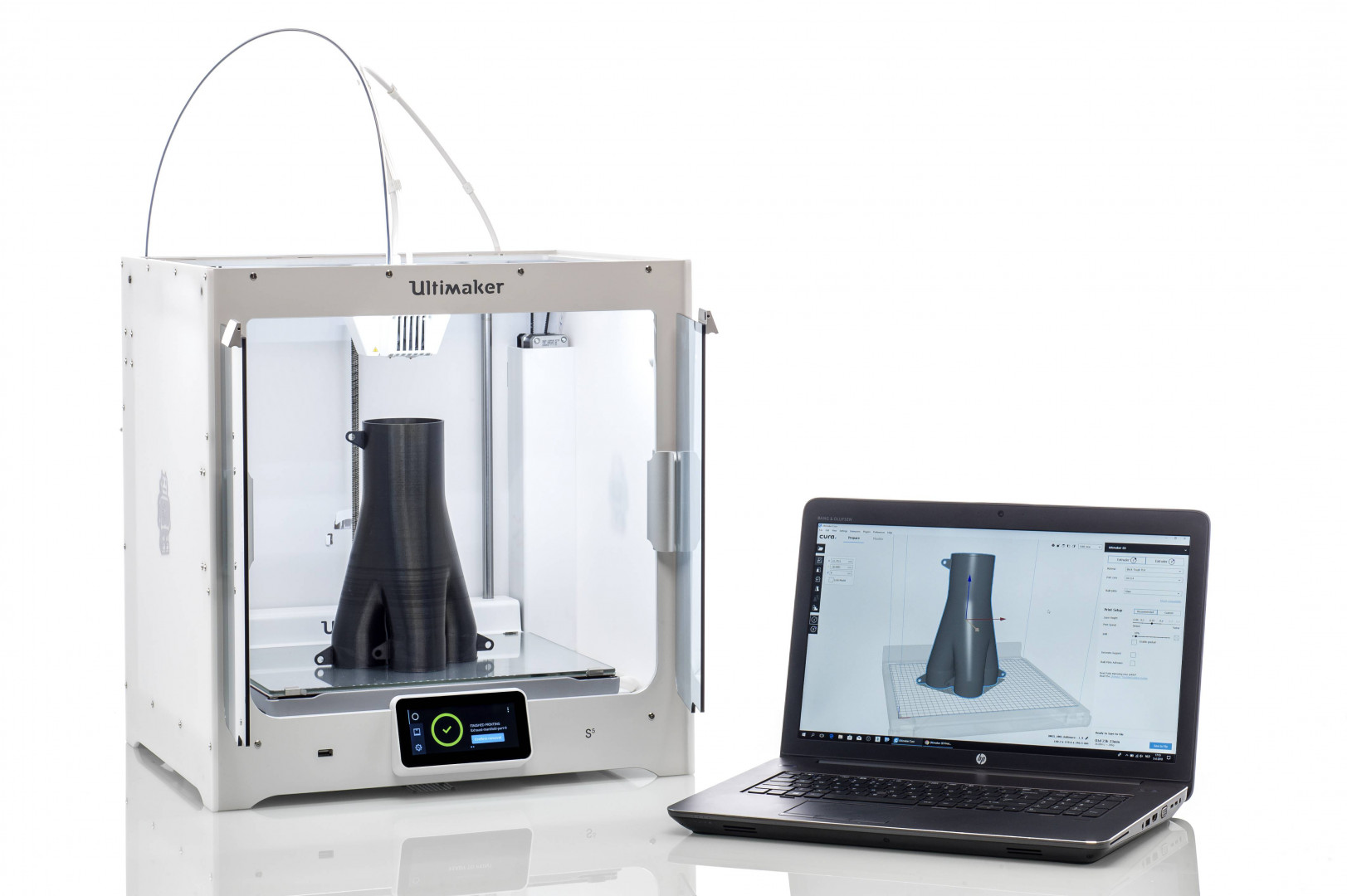

3D printing solutions provider and reseller Dynamism has added the new Ultimaker S5 3D printer to its product range. The company will provide customers with pre-order advice, on-site or web-based installation and training, and quality-assurance for Ultimaker’s new 3D printer.

Despite rapid advancements, desktop 3D printing is still the new tech on the block. New functions and applications are constantly being discovered and many institutions are interested in incorporating 3D printing into their workflow. However, many of these institutions may not know exactly what kind of printer they require.

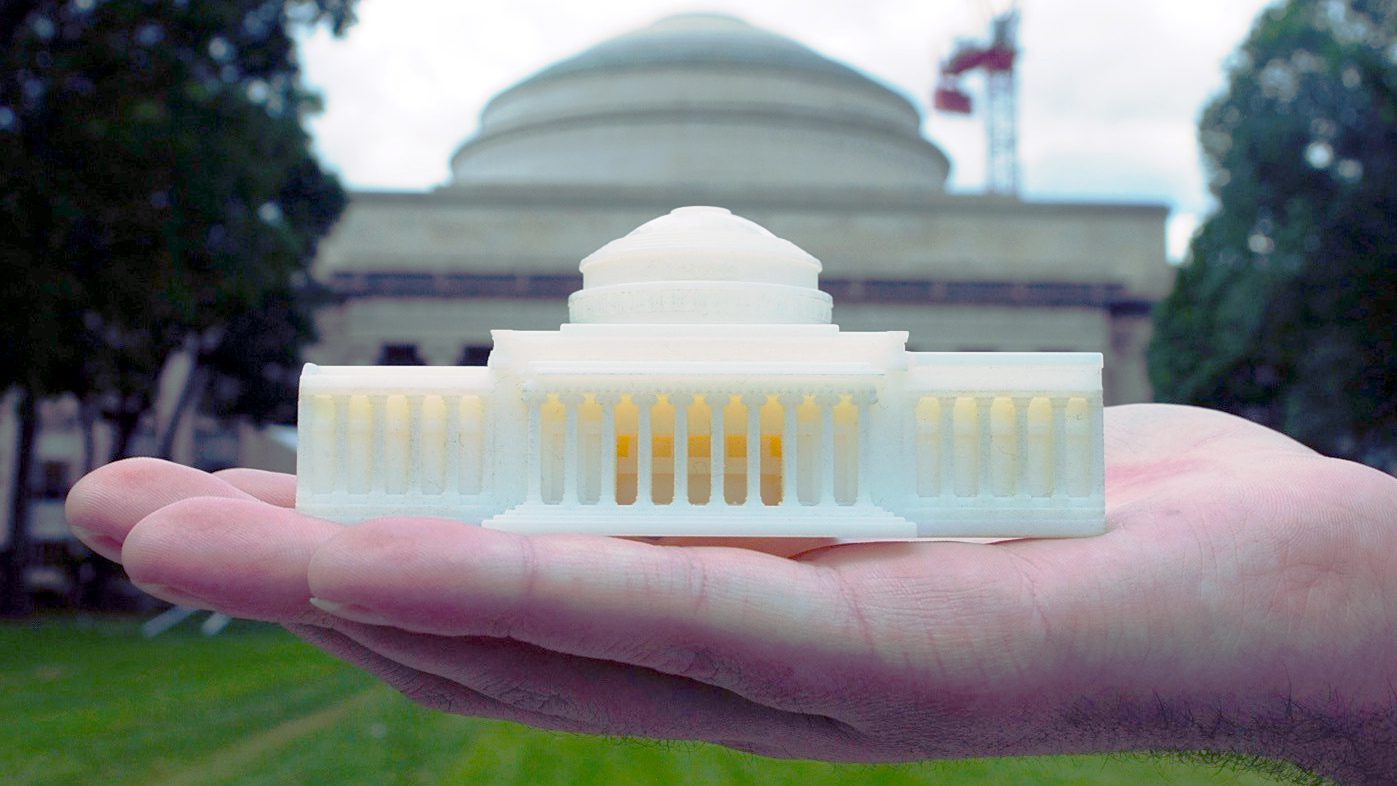

Say a University is interested in incorporating 3D printing into its curriculum. It will likely require a printer that yields high prints per hour for several students and produces reliable end-product quality.

The desktop 3D printing brand Ultimaker is already popular among schools. Duke University worked with the reseller Dynamism on its deployment of over 100 Ultimaker 3D printers.

A stellar option is the just announced Ultimaker S5, which is being showcased by Dynamism at the Rapid + TCT Show in Ft. Worth, Texas. The Ultimaker S5 is available for $5,995 in the U.S. Shipping to customers begins May 15th.

Dynamism Offers Pre-Order Advice, Installation and Training for Ultimaker S5 3D Printer

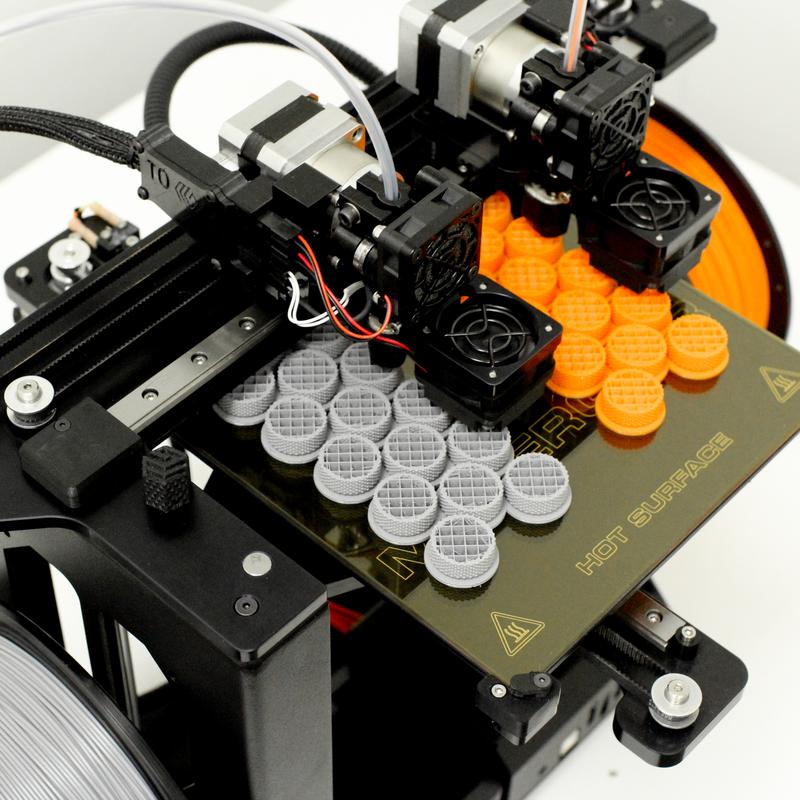

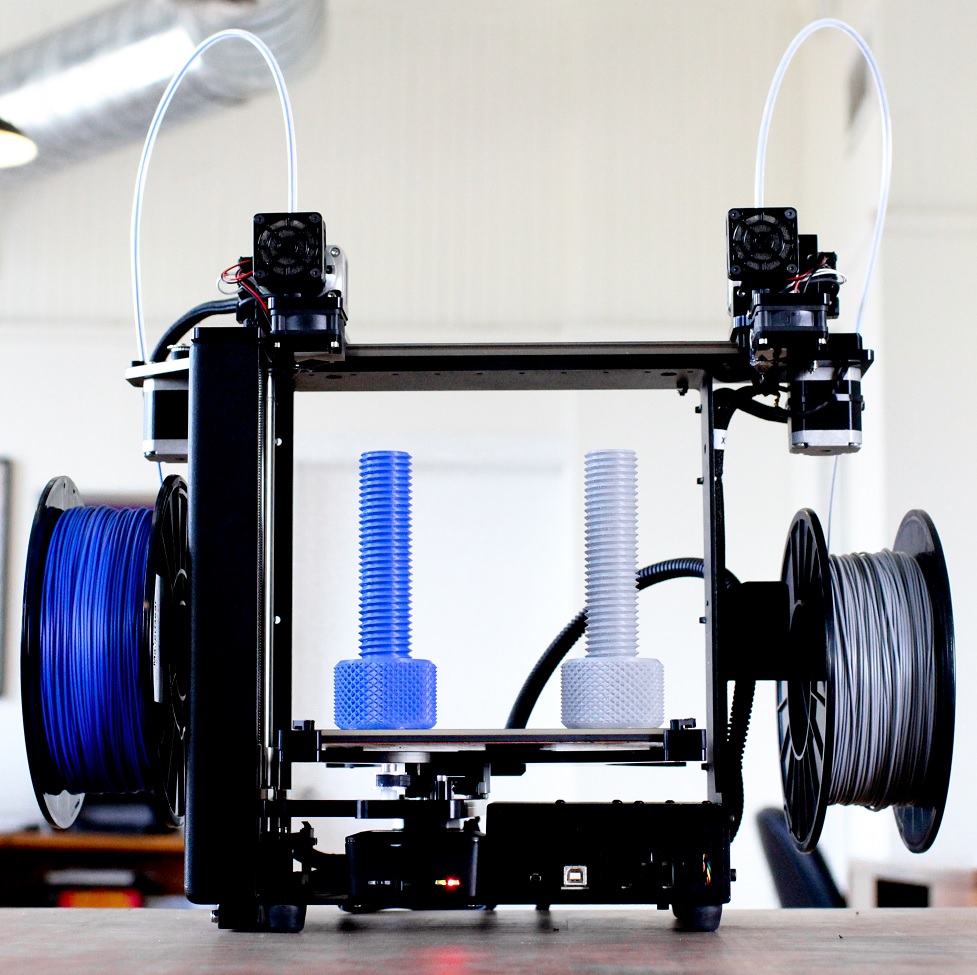

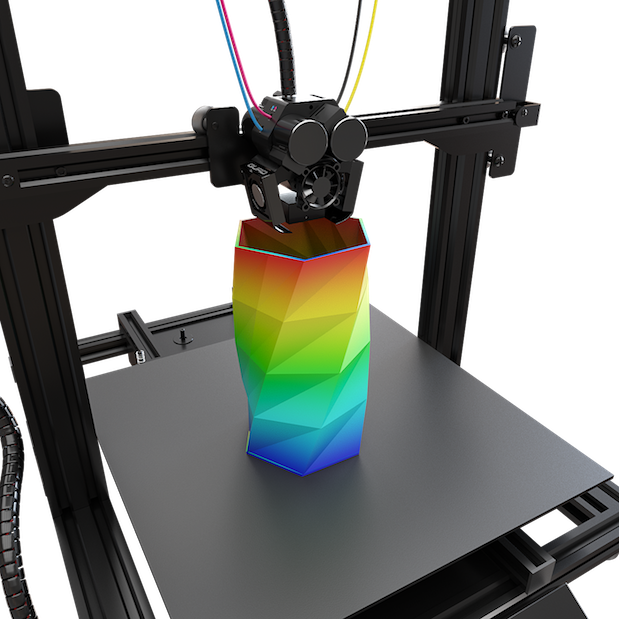

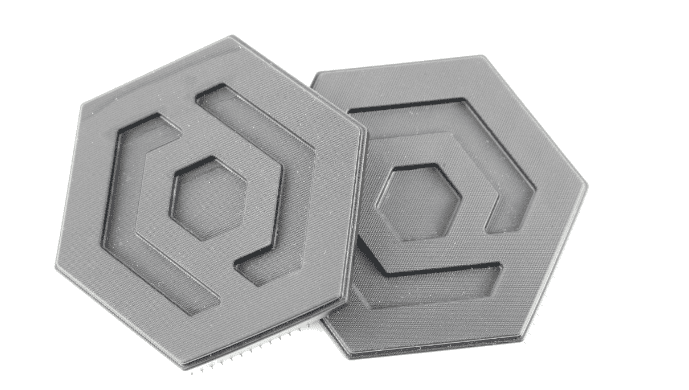

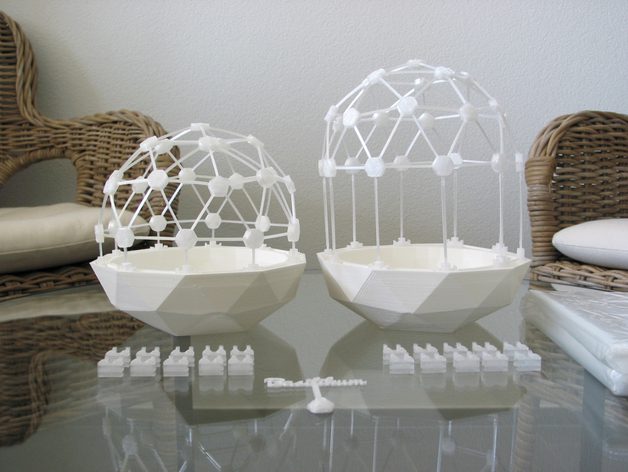

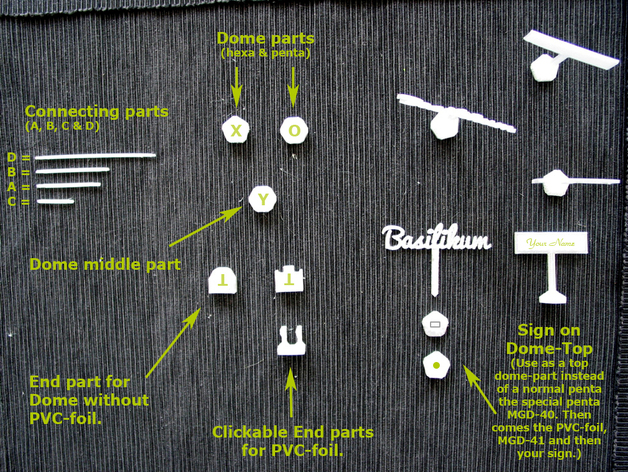

The Ultimaker S5 brings several advancements to what is already the gold standard of desktop 3D printing. The printer includes a larger build volume than found on the Ultimaker 3. This allows for more options in printing functional prototypes, manufacturing tools, and end-use parts. Dual extruders allow for simultaneous printing of parts and structures on the Ultimaker S5, ensuring high yield of accurate prints.

All Ultimaker products include automatic NFC detection of when Ultimaker filament and used. Thanks to Cura’s print profiles, optimal print settings are configured automatically.

With the Ultimaker S5, the brand brings its Cura Connect platform to mobile with apps available for iOS and Android. Users can connect and manage multiple printers at any time and from any location, such as in and outside of the classroom. In fact, university and high school printing labs can take advantage of the Cura Connect feature found on Ultimaker 3D printers, which allows users to connect and manage multiple printers with plug-and-play ease.

Ultimaker continues to expand its filament options. The Ultimaker S5 will ship with a new Tough PLA filament. The new material has strength comparable to ABS, but is more flexible than standard PLA and provides a higher-quality matte finish. Tough PLA will be available in sold separately and is also compatible with the Ultimaker 3.

The manufacturer has just announced a partnership, with leading chemical companies, to standardize material profiles to provide enterprises using Ultimaker printers with access to a wide range of high-level engineering plastics and composites. Members of the alliance program DSM, BASF, Sabic, Dupont, Owens Corning, Mitsubishi, Henkel, and Clariant.

Measured by the cost of ownership, the Ultimaker S5 offers tremendous value–thanks to its uptime, and printed parts reliability. Purchasing the Ultimaker S5 through Dynamism to receive pre-order advise, on-site or web-based installation and training, to delivery and beyond, ensuring a long life and quality production from the Ultimaker S5 or any Ultimaker 3D printer.

Dynamism is now taking orders for the Ultimaker S5.

Website: LINK