A 3D printing cafe (yes, that’s a thing) will attempt to 3D print the world’s largest single piece camper trailer. Weighing 600 lbs and 13 feet long, the mega project will be streamed live on the cafe’s Facebook page.

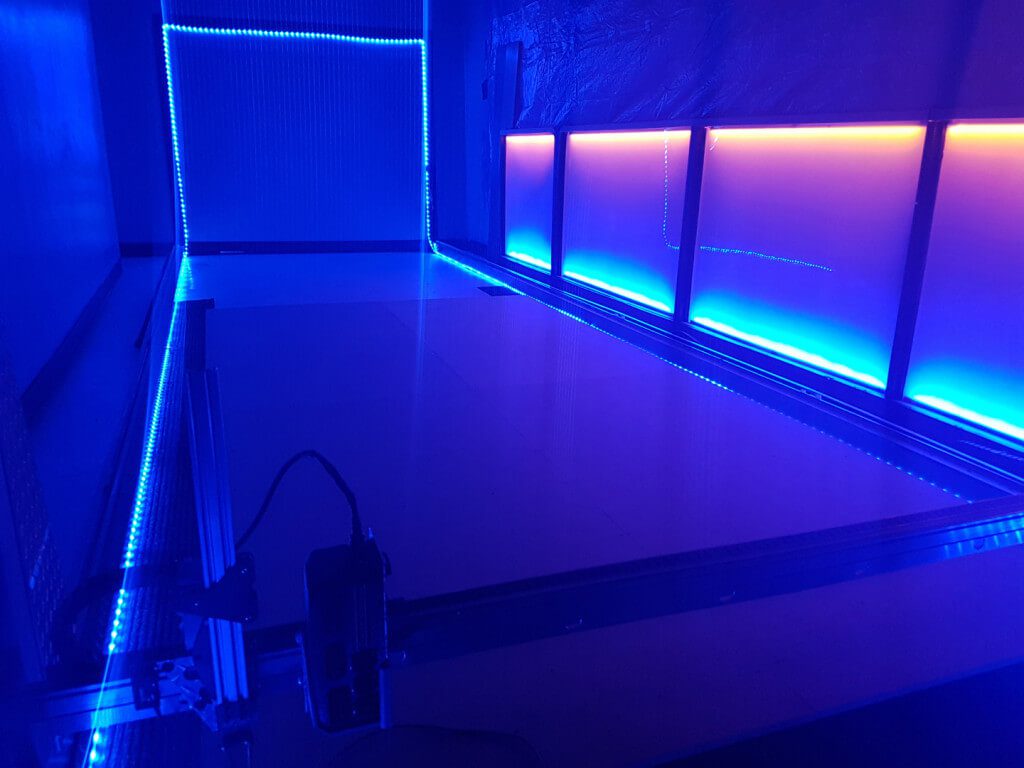

A prototype 3D printed camper van, the Wave, will be fabricated live for all to see from Thursday, February 8th. The project, an in-house effort of Create Cafe 3D with the help of Saskatchewan Polytechnic, will see a 28-foot long ErectorBot 3D printer do the heavy lifting, extruding some 600 lbs of PETG provided by a proprietary hopper.

The Wave is planned to become a commercial line of camper trailers available in three sizes — 13-, 16- and 19-feet — sold by Wave of the Future 3D. Founded by Randy Janes (who is also a member of the Create Cafe team), Janes is also the owner of the ErectorBot that will be housed in Create Cafe 3D for the duration of the print.

This exercise has been long in the making, with Janes approaching Create Cafe 3D CEO Dustin Maki way back in 2016 with the premise of printing “the worlds first full-size camper”. Two years later the plan is coming to fruition, with Janes’ behemoth 3D printer installed in the cafe ready to undertake a 10-14 day print job in full view of Create Cafe 3D’s coffee-swigging customers.

It’s well and good making bombastic claims to world-firstedness, but what exactly makes the Wave stand apart? What are the benefits of 3D printing a camper trailer?

Creating the Custom Camper

For one, Wave of the Future and Create Cafe 3D claim a 100 year life expectancy from a PETG 3D printed camper. By printing a watertight single shell design, they plan to eliminate the primary cause of degradation in campers: water damage. No seams between sheet metal or wood like found on traditional campers means no way for water to seep inside and degrade the materials.

The material properties of PETG also contribute to such hardiness, with abrasion resistance the cited benefit here.

Given the large nature of the print job, any optimization is a welcome thing. To this, a partnership with Saskatchewan Polytechnic resulted in an applied research project provided high-flow printing nozzles, without which the collaboration claims it could not succeed.

The prototype Wave was designed in Fusion 360 and sliced in Simplify3D by Create Cafe 3D’s Head of Design, Duncan Boyes.

Looking to whip up greater public interest in 3D printing in Canada, the printing of the Wave will be live-streamed on Create Cafe’s Facebook page on February 8th, 12pm CST (the company originally communicated February 5th for the stream, but a customs issue with the Wave’s PETG pellets has forced the project back).

Although if you’re in the neighborhood, you could always pop in for a coffee and check it out in person.

Website: LINK

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.