We were lucky to be given a tour of the facilities where machines, robot arms, and real people make 250,000 Raspberry Pi computers a week – from board to box. Have you ever seen a machine put a little computer in a box? It’s very cute, and the mechanism to fold the lid is a very simple angled piece of metal that runs along the line, maintaining the key engineering philosophy of KISS (keep it super-simple, as our friends at the Raspberry Pi Foundation like to say it).

Eco friendly

A (rightful) concern of many people is the environmental impact of manufacturing products, and a key part of the operation of the Pencoed site is meeting sustainability targets which are set every five years. From using more green energy to reducing waste of all kinds, Sony is taking active steps towards reducing its environmental impact.

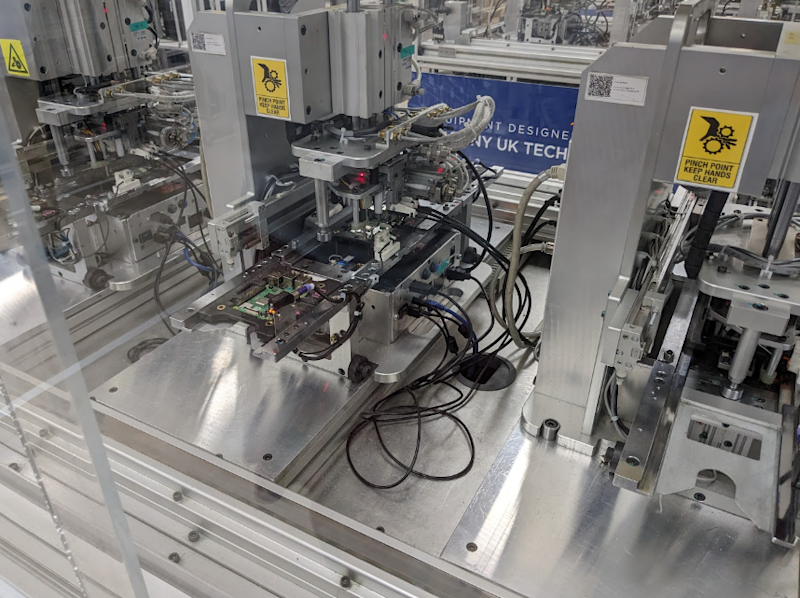

You can see this along the lines, with (human-supervised) automated checks to make sure all chips are installed correctly. Misaligned chips can usually be reset which cuts down on waste and overall improve yield, and the reflow soldering methods (described in our engineering interview in The MagPi 134 in the new Raspberry Pi 5 manufacturing process (referred to by a codename of Hydrogen in the factory) that also improve the number of working boards.

The factory floor itself is divided up into areas with clear signs on what section is which. On one station you’ll have someone building a broadcast camera from scratch, with two a week going out the doors, and in another section you’ll have people snapping boards off runners to be fed into the boxing machine. The complexity is impressive to behold, with a lot of custom machines built and maintained by Sony to make the humble Raspberry Pi.