After studying the mechanisms of invertebrates in nature, U.S. Army researchers have developed 3D printed soft robotics that can traverse difficult landscapes and squeeze into crowded spaces.

A joint project between the U.S. Army Research Laboratory (ARL) and the University of Minnesota (UMN) is exploring 3D printed soft robotics that can squeeze into tight spaces and travel around obstacles, essentially acting like invertebrates.

Previously, the U.S Army has had to settle for rigid and inflexible robots, making it difficult to maneuver in crowded places and congested environments.

The current limitations of military robots include a lack of dynamic flexibility, which is due to their rigid components. Additionally, these robots also require the U.S. Army to activate complex mechanisms and electrical circuits.

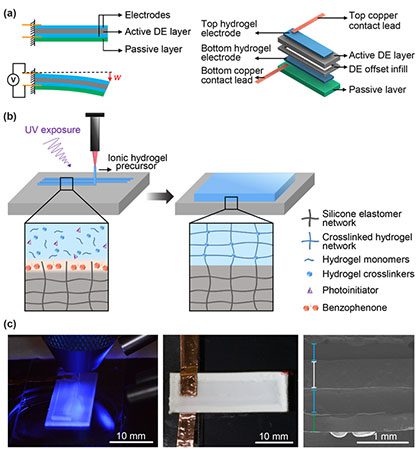

And so, the ARL and UMN are using tunable materials to develop the first soft robotic prototypes. The team is also able to modify the structural flexibility, morphology, and dynamic actuation of the 3D printed robot.

The final 3D printed prototype is the first of its kind, able to perform bending motions and squeeze into tight spaces.

“Successful stealthy maneuvering requires high structural flexibility and distributive control to sneak into confined or restricted spaces, operate for extended periods and emulate biological morphologies and adaptability,” explained Dr. Ed Habtour, an ARL researcher who studies nonlinear structural dynamics.

Using Nature to Advance 3D Printed Soft Robotics

During the first phase of research, the UMN team observed different methods that would allow them to “emulate the locomotion of invertebrates”. By doing so, they gained insight into soft distributed actuation circuitries that can perform high bending motions without skeletal support.

After looking at mechanisms in nature boast flexible abilities, the team developed a customized 3D printing platform and mathematical model to study and predict these optimal actuation mechanisms. UMN then 3D printed the first actuation circuitries using soft and stretchable materials that have mechanical features inspired by nature.

“The research findings represent an important stepping stone towards providing the Solider an autonomous freeform fabrication platform – next-generation 3-D printer, which can print functional materials and devices – to generate soft actuators and potentially tetherless soft robots on demand, on the fly and at the point of need,” Habtour said.

Not only are the 3D printed actuators incredibly flexible, they can also be manufactured without post-processing and are extremely easy to use. In the next phase of the project, the team plans to focus on the interplay of internal interfaces and interaction kinetics observed in biological systems.

The current research has been published in Extreme Mechanics Letters.

Source: U.S. Army

Website: LINK