Schlagwort: Ultimaker

-

Interview with Ultimaker: Looking at the Ultimaker S5 and Shift Towards Professional Market

Reading Time: 13 minutesAll3DP travelled to Hannover Messe 2018 to witness the unveiling of the new Ultimaker S5 3D printer. To learn more about this professional-grade 3D printer and the company’s refined focus, we sat down with to Siert Wijnia, the co-founder of Ultimaker; and Paul Heiden, Senior VP of Product Management. Back in 2011, a…

-

Dynamism Adds New Ultimaker S5 3D Printer to Extensive Portfolio

Reading Time: 4 minutes3D printing solutions provider and reseller Dynamism has added the new Ultimaker S5 3D printer to its product range. The company will provide customers with pre-order advice, on-site or web-based installation and training, and quality-assurance for Ultimaker’s new 3D printer. Despite rapid advancements, desktop 3D printing is still the new tech on the…

-

Ultimaker Launches Alliances Program to Improve 3D Printing Material Profiles

Reading Time: 3 minutesWith the new Ultimaker Alliances Program, users will be able to load preconfigured material profiles and 3D print settings from leading material manufacturers. Here’s a second big announcement from Ultimaker; the 3D printing company is embarking on a series of collaborative alliances with a number of global material companies to meet demand…

-

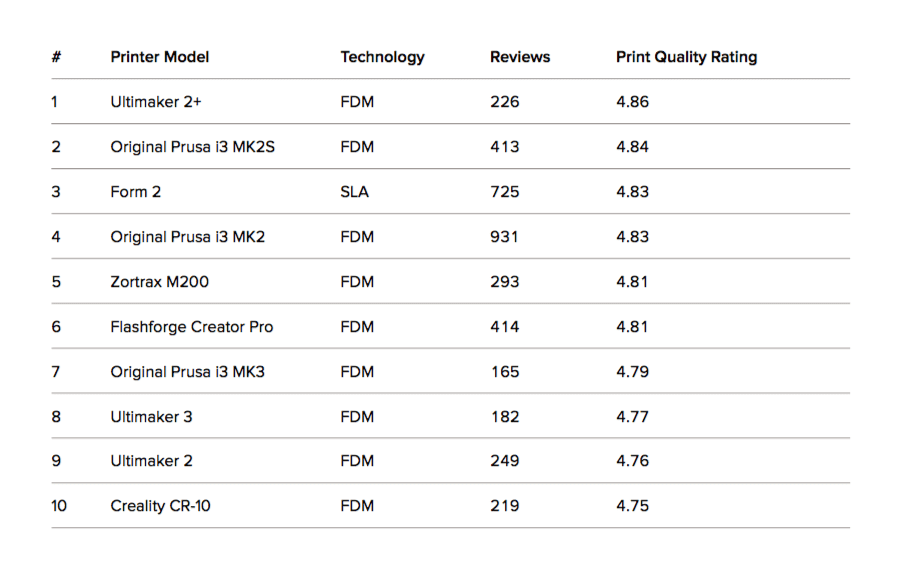

Ultimaker and Prusa Vie for Dominance in 3D Hubs Trend Report

Reading Time: 5 minutesUltimaker! HP! Prusa Research! New York City! Some fascinating insights into the 3D printing industry, courtesy of the latest 3D Hubs Trend Report. It’s the beginning of a new business quarter, and for 3D printing fanatics that means only one thing. It’s time for another 3D Hubs Trend Report. The 3D Hubs…

-

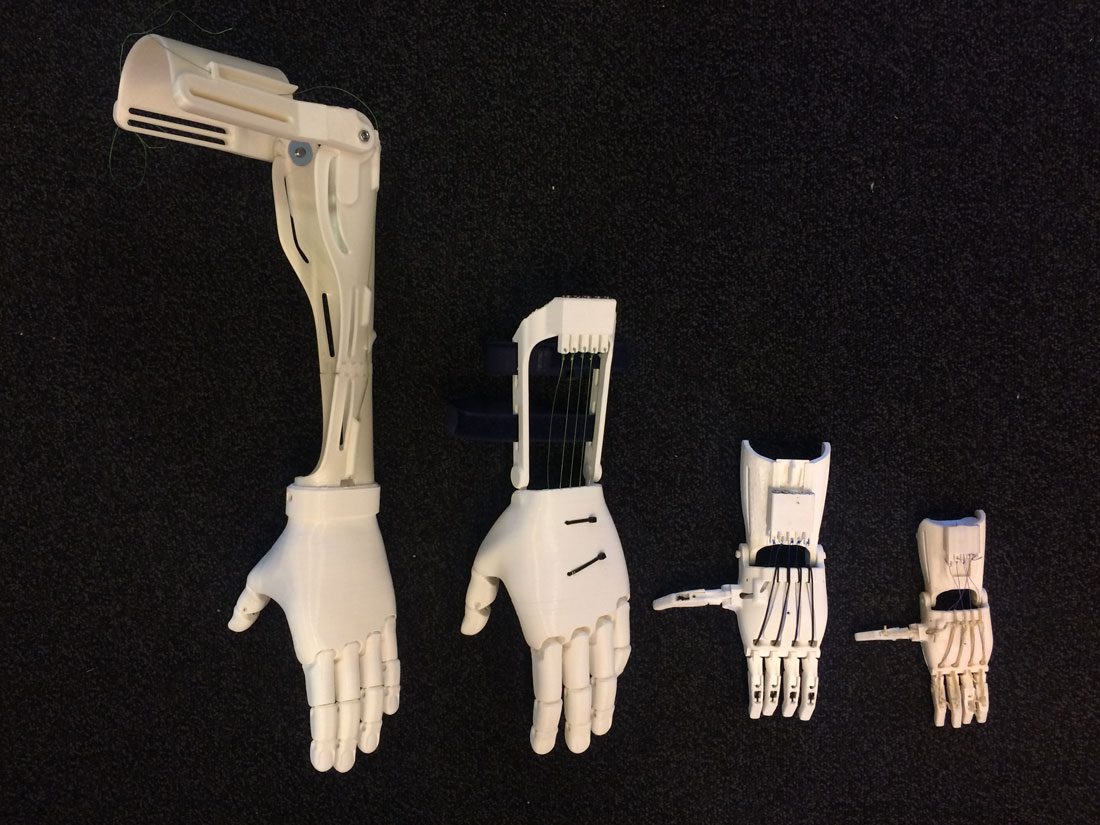

How 3D Printing Empowers Locals in Sierra Leone

Reading Time: 3 minutesSurgical resident Lars Brouwers brings aid to Sierra Leone by providing training and materials in 3D printed functional prostheses to local citizens. Between 1991 and 2002, a civil war took place in Sierra Leone that left hundreds of innocent citizens with life-changing injuries. To support those affected by the loss of their…

-

![[DEAL] Ultimaker 3D Printers (Refurbished), 10-15% Off at MatterHackers](data:image/svg+xml;charset=utf-8,%3Csvg xmlns%3D'http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg' viewBox%3D'0 0 1920 1080'%2F%3E)

[DEAL] Ultimaker 3D Printers (Refurbished), 10-15% Off at MatterHackers

Reading Time: 2 minutesWe’ve spotted some refurbished Ultimaker 2+, 3 and 3 Extended 3D printers over at MatterHackers. Limited in number, they’re a rare chance to get an Ultimaker with $$$ off the usual retail price. We like the Ultimaker 3. Easy to use and reliable dual extrusion machines, there’s a reason we crowned it…

-

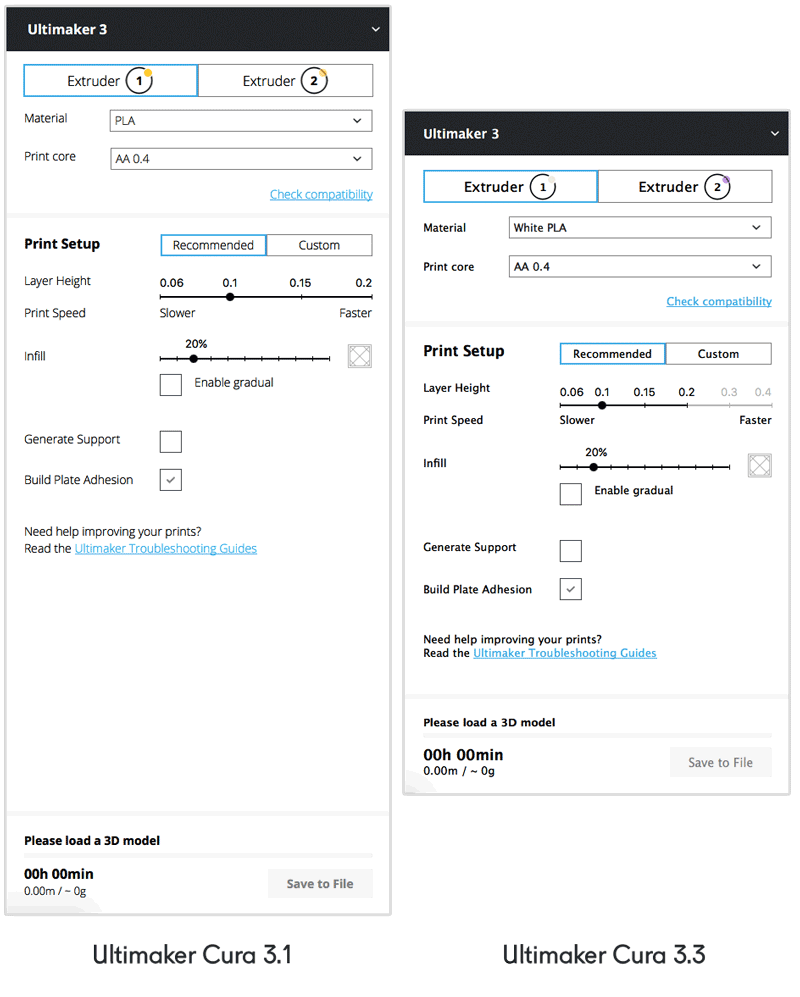

Ultimaker Releases New and Improved Cura 3.3 Beta

Reading Time: 3 minutesUltimaker is releasing a new beta version of its popular slicing software. You can now download Cura 3.3 now from the company’s website. As usual, the software is free. In February 2018, 3D printer manufacturer Ultimaker released its latest stable version of the Cura 3.2.1. It added experimental support structures, new layer features.…

-

3D Printing and Distributing the Fittle Puzzle to Help People in India Learn Braille

Reading Time: 3 minutesFittle is the world’s first 3D printed braille puzzle which is open source. It helps visually impaired people in India learn to read braille quickly and efficiently. In India, 22 million people are visually impaired and many of them can’t find work. The ability to read braille offers them a chance to be…

-

Bosch Invests in Ultimaker 3 Extended 3D Printers to Boost Global Production

Reading Time: 3 minutesThe German automotive parts supplier will be implementing Ultimaker 3 3D printers across its locations worldwide to streamline production. Manufacturing companies are turning increasingly to additive manufacturing to boost their parts production. According to research by International Data Corporation (IDC), the market for 3D printing technologies will reach $12 billion in 2018.…

-

Ultimaker Becomes Sponsor and Supplier for GE’s Additive Education Program

Reading Time: 2 minutesOpen source 3D printer manufacturer Ultimaker has announced that it is now a sponsor and supplier to the GE Additive Education Program (AEP). Schools can apply for subsidies from General Electric towards 3D printing. General Electric is helping future engineers, makers and scientists thrive with their GE Additive Education Program (AEP). The…

-

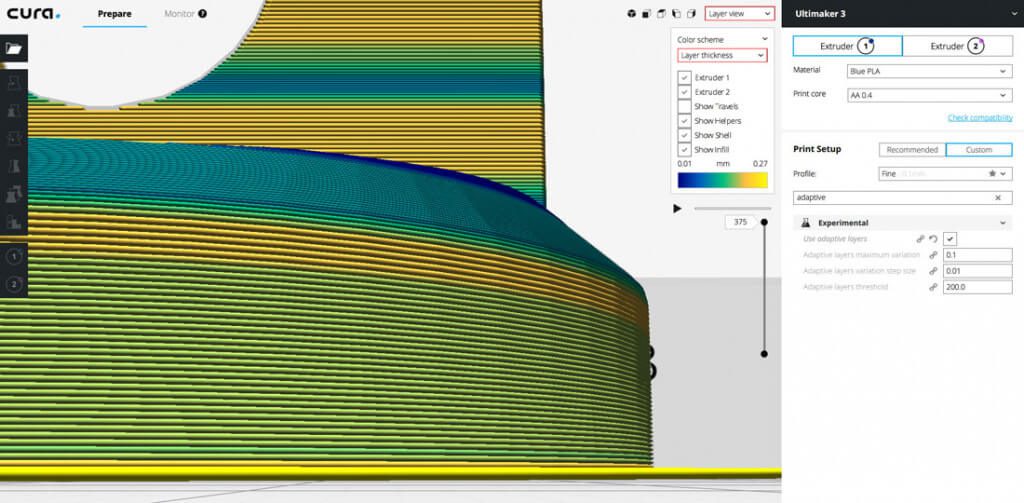

Ultimaker Cura 3.2 Adds Experimental Supports and Layer Features, Improves UI

Reading Time: 3 minutesUltimaker is releasing its stable version of Cura 3.2 after a few weeks of beta testing. You can now download the popular 3D slicing software from the company’s website. As usual, the software is free. In mid-January,3D printer manufacturer Ultimaker released the beta version of the Cura 3.2, its latest update of…

-

Best 3D Printer Awards 2017 / 2018 – The 12 Best 3D Printers

Reading Time: 4 minutesSelecting the best 3D printer for your needs is not an easy task. We want to make the process it a little bit easier with All3DP’s Best 3D Printer Awards. Finding the Best 3D Printer for Beginners If you are a newcomer to 3D printing, things can get overwhelming. Specifications and terminology…

![[DEAL] Ultimaker 3D Printers (Refurbished), 10-15% Off at MatterHackers](https://www.blogdot.tv/wp-content/uploads/2018/03/deal-ultimaker-3d-printers-refurbished-10-15-off-at-matterhackers.jpg)