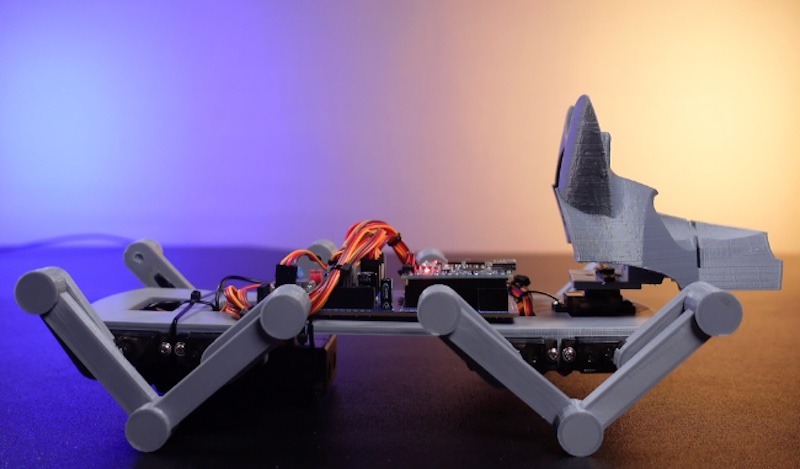

Reading Time: 4 minutesThis month we have the hotly anticipated Argon ONE V3 M.2 NVMe PCIe Case. Hopes are high for this one and we can tell you it hits home runs all the way. Redesigned for Raspberry Pi 5 this board combines the features of the Argon ONE V2 with the – previously separate – M.2 Expansion Board add-on to create an all-in-one computer case with super-fast, and super-large, storage that also cleverly uses passive cooling and heatsinks to keep everything running. This is the one we have been waiting for.

All together now

The Argon ONE is Argon40’s flagship case, containing a daughterboard for Raspberry Pi that adds additional features such as full-sized HDMI sockets and an infrared (IR) receiver.

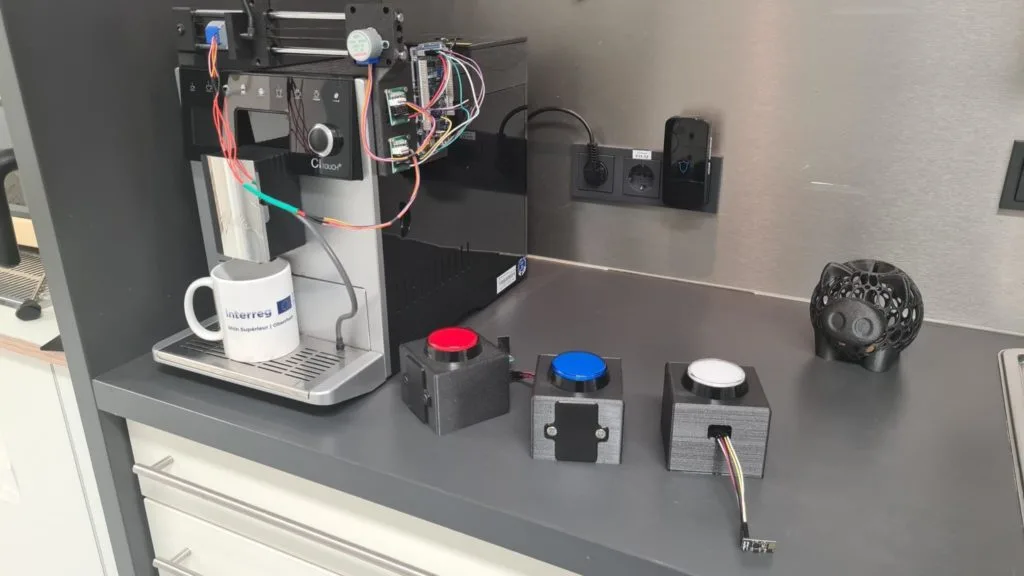

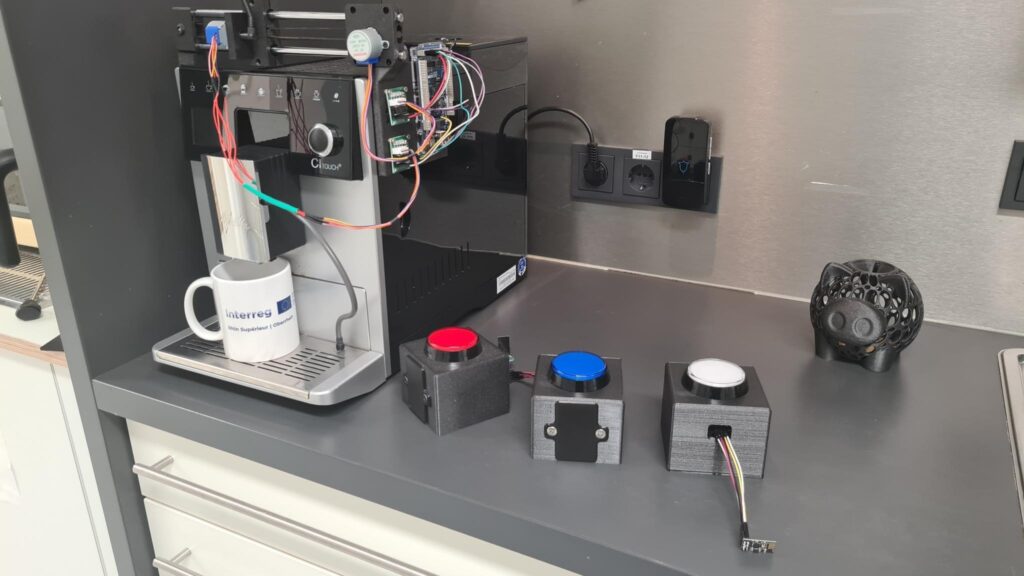

On the base of Argon ONE V3 is a removable cover that provides access to the M.2 NVMe socket. Here you can insert any M.2 NVMe with M-Key up to 2280 size. The flap is marked “THERML” which nods to its aluminium heatsink and a long strip of thermal pad is included to transfer the heat out into the case.

Two more silicon pads are included to connect Raspberry Pi’s CPU and PMIC (Power Management Integrated Circuit) to the case.

Alongside this impressive passive cooling is a redesigned 30mm fan and blower. This is repositioned at an angle to be “more efficient and quiet”, and we found it unobtrusive even when stress testing.

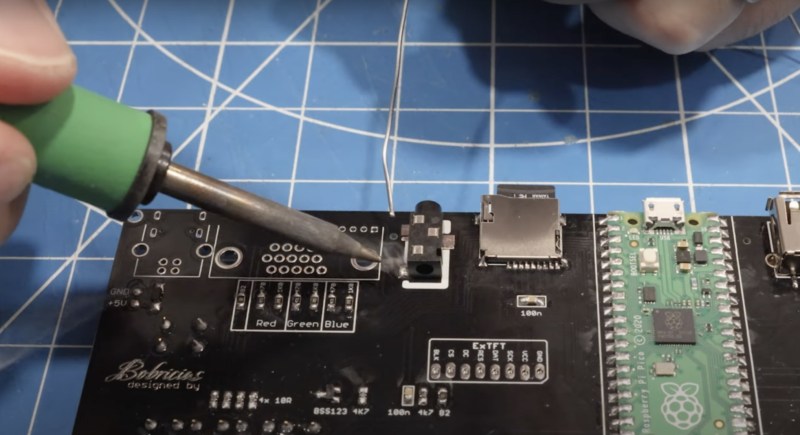

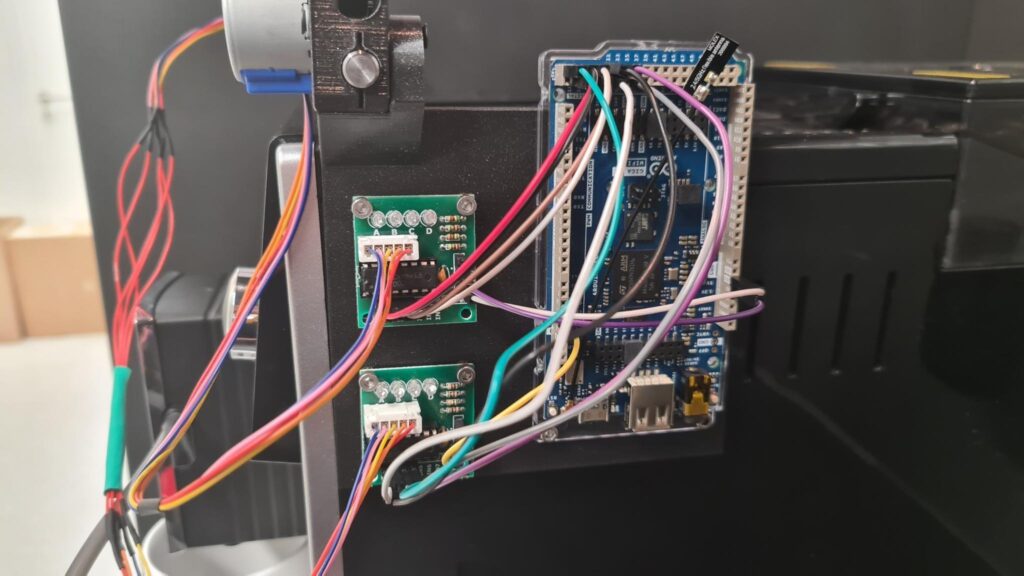

Argon ONE V3 now sports Raspberry Pi’s RP2040 microcontroller to control various functions like fan speed and power management (via jumper pins on the daughter board). The power button is less of a novelty now that Raspberry Pi 5 itself features one. However, the presence of a 3.5mm audio jack will be a welcome addition for audio buffs now that it has been removed from Raspberry Pi 5’s main board.

One advantage over the Argon ONE V2 board is that the M.2 NVMe now connects directly to the PCIe socket on Raspberry Pi 5. This leaves all four USB-A sockets available.

A removable magnetic flap on top of the case provides access to repositioned GPIO pins alongside a handy pinout guide.

Assembly and testing

Putting together the Argon ONE V3 was a relatively painless process thanks to the included assembly instructions. Raspberry Pi 5 is connected to the HDMI daughterboard, and the PCIE cable is used to connect the bottom half of the case to Raspberry Pi 5. Then the whole thing is screwed together. Finally, the M.2 NVMe storage is connected to the underside making it possible to upgrade the drive without opening the whole case.

As with previous Argon ONE cases, the microSD card is hidden away and can’t be used without opening up the case. This is less problematic these days as a USB thumb drive flashed with Raspberry Pi OS can be used to run Imager and flash the storage drive. Attach an Ethernet cable and you can also use Network Install with Raspberry Pi 5.

Speed-testing of the NVMe drive tells you much more about the quality of your drive than the case itself. We used a 500GB WD Blue storage stick and measured the speed using Raspberry Pi OS’s built-in Raspberry Pi Diagnostics tool to test performance. It returned a sequential write speed 789590 KB/sec (790 MB/s) almost 80 times faster than the recommended pass speed for a microSD card. It’s fast.

The heat test is also interesting. We used stress –cpu 4 and measured the output with the script found here for 15 minutes.

Raspberry Pi 5 inside the Argon ONE V3 case idles at around 54°c (down from the 65°c baseline of an uncooled Raspberry Pi 5 without a heatsink). We found the fan kicked in at the 60°c mark after five minutes and kept the Raspberry Pi 5 hovering around 61°c for another 10 minutes. At no point did Raspberry Pi OS reach the 80°c mark where performance throttling begins. It compared favourably to a Raspberry Pi 5 and an official Active Cooler unit.

Put it to use

One optional extra we should mention is an internal Argon ONE BLSTR DAC audio board upgrade, which will be sold separately. Alongside the 3.5mm jack this will make Argon ONE V3 ideal for audio fans. We didn’t have one for testing and can’t see it on the Argon40 website just yet, so hopefully that will come down the line.

All of this transforms Raspberry Pi 5 from a hackable board to a desktop computer. A role our favourite computer is increasingly fulfilling with aplomb. The built-in infrared connection, large storage, and full-sized HDMI connection also ensure Argon ONE V3 becomes the perfect media player or home games console. This case is highly recommended.

Verdict

10/10

An excellent case that sees a lot of Argon’s ideas reach fruition. Turn your Raspberry Pi 5 into a smart desktop computer, media player, games console or DAC audio player.

Specs

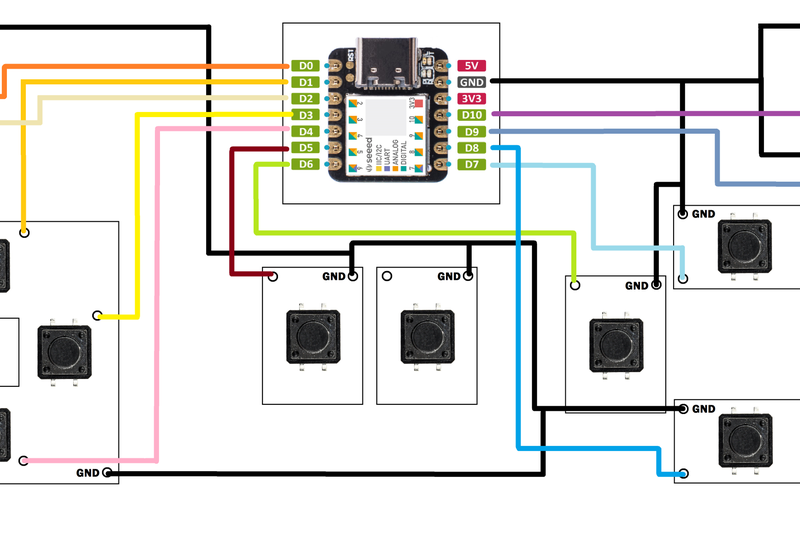

Components: Argon ONE Pi 5 V3 case, M.2 NVME carrier board, Video/Audio PCB extender (daughterboard), GPIO & Fan board, RP2040-based microcontroller

Input/output: Adjustable M.2 NVME with M-Key up to 2280 size, 2 × standard (type A) HDMI ports, Ethernet, 4 × USB-A ports, USB-C power port, 3.5mm audio jack

Cooling: Aluminium alloy case for passive cooling, blower type PWM programmable 30mm fan