Schlagwort: robotic hand

-

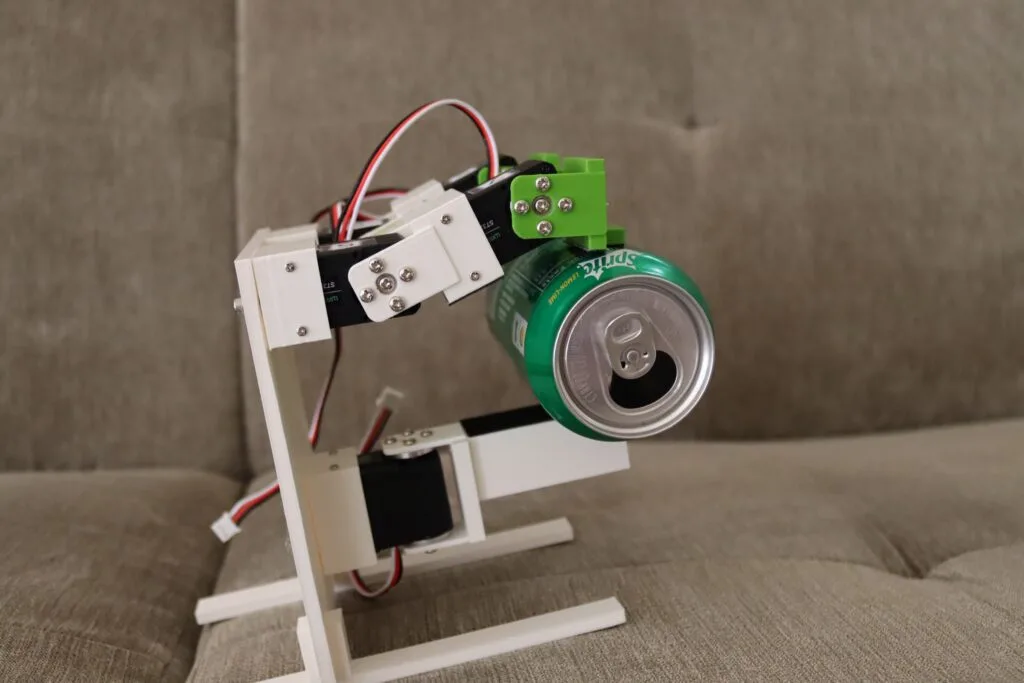

This three-fingered robot hand makes use of serial bus servos

Reading Time: 2 minutesA small startup called K-Scale Labs is in the process of developing an affordable, open-source humanoid robot and Mike Rigsby wanted to build a compatible hand. This three-fingered robot hand is the result, and it makes use of serial bus servos from Waveshare. Most Arduino users are familiar with full-duplex serial communication,…

-

This bionic hand responds to motion control

Reading Time: 2 minutesBuilding a robot is only half the battle, because you also need a way to control it. Something like a rover may work with a simple joystick or even typed commands. But complex robots often have many motors and controlling those all directly becomes a challenge. That’s why Will Cogley chose motion…

-

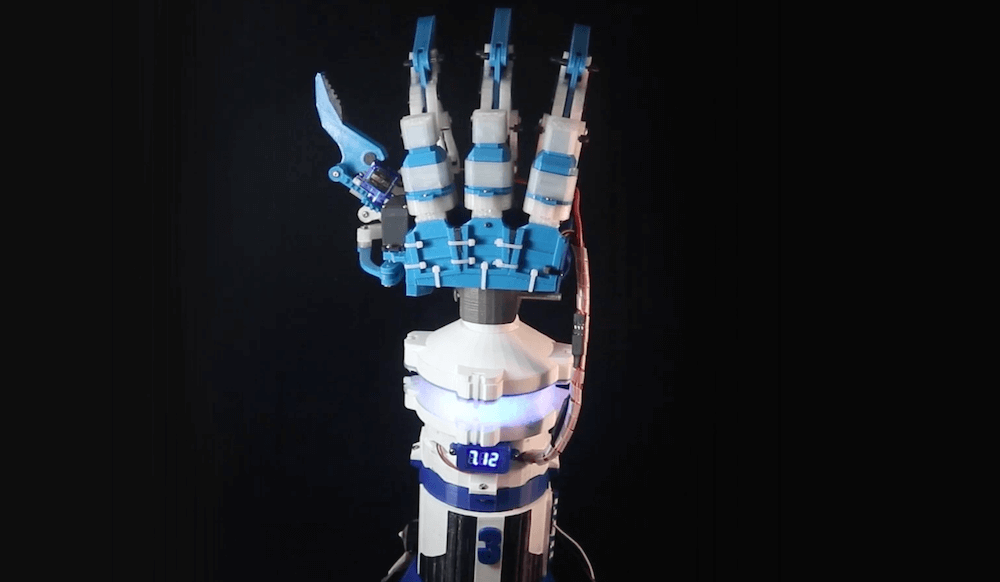

This gargantuan 3D-printed robot hand is just the beginning

Reading Time: 2 minutesIvan Miranda has a humble dream: he wants to build a massive 3D-printed robot that he can ride upon. In other words, he wants a mech. But that is obviously a very challenging project that will take an incredible amount of time and money. So he decided to test the waters with…

-

Controlling a bionic hand with tinyML keyword spotting

Reading Time: 2 minutesArduino Team — August 31st, 2022 Traditional methods of sending movement commands to prosthetic devices often include electromyography (reading electrical signals from muscles) or simple Bluetooth modules. But in this project, Ex Machina has developed an alternative strategy that enables users to utilize voice commands and perform various gestures accordingly. The hand itself was made…

-

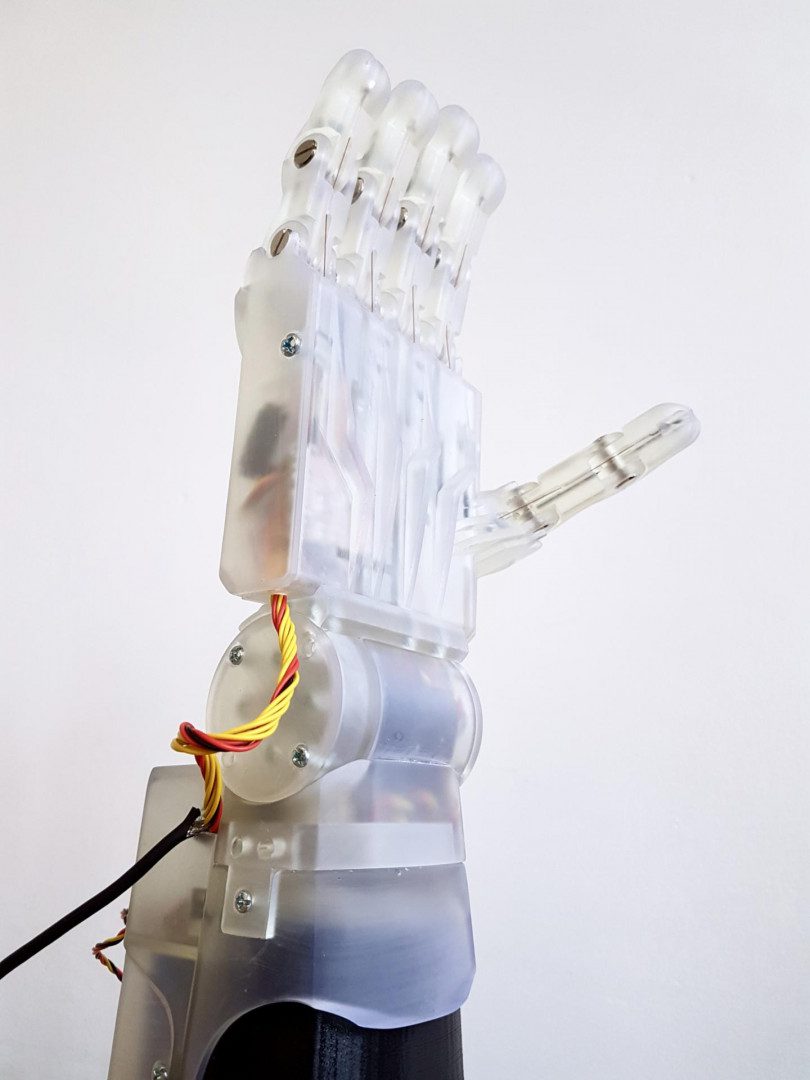

Designing a modular and ambidextrous four-fingered robot hand

Reading Time: 2 minutesDesigning a modular and ambidextrous four-fingered robot hand Arduino Team — September 4th, 2019 Gray Eldritch (AKA The Technomanc3r) has been working on a robotic hand for some time now, and has settled (so far) on a design with three independent servo-actuated fingers and a thumb. He’s also implemented a wrist assembly…

-

Researchers 3D Print Functional Robotic Prosthetic Hand at a Fraction of the Cost

Reading Time: 3 minutesResearchers from the University of Manchester have developed an extremely affordable 3D printed robotic prosthetic hand. The assistive device enables groundbreaking functionality for amputees, and can be fully customized for the user via an Android app. A team of designers from the University of Manchester have recently created a robotic hand prosthetic with…

-

Boy gets prosthetic hand made by 3-D printer

Reading Time: < 1 minuteTwo years ago, Paul McCarthy began searching for an inexpensive yet functional prosthetic hand for his son Leon, who was born without fingers on one of his hands. McCarthy came across a video online with detailed instruction on how to use a 3-D printer to make a prosthetic hand for his…