Schlagwort: Recycling

-

This robot turns old bottles into a musical instrument

Reading Time: 2 minutesPercussion instruments are likely the first kind that humanity invented, because they’re quite simple: hit a thing and a noise happens. Different things produce different frequencies with different timbres, and glass bottles have a nice xylophonic sound to them. Because glass bottles are easy to find among discarded garbage, Jens of the…

-

This recycling bin sorts waste using audio classification

Reading Time: 2 minutesAlthough a large percentage of our trash can be recycled, only a small percentage actually makes it to the proper facility due, in part, to being improperly sorted. So as an effort to help keep more of our trash out of landfills without the need for extra work, Samuel Alexander built a smart recycling…

-

This bin will sort your trash and recyclables automatically

Reading Time: < 1 minuteThis bin will sort your trash and recyclables automatically Arduino Team — February 18th, 2021 Often you might see a recycling bin next to a trash can, and notice that someone else has thrown their waste into the wrong container. To help with this conundrum, the team of Shalin Jain, Viraj Singh, Edward Chen,…

-

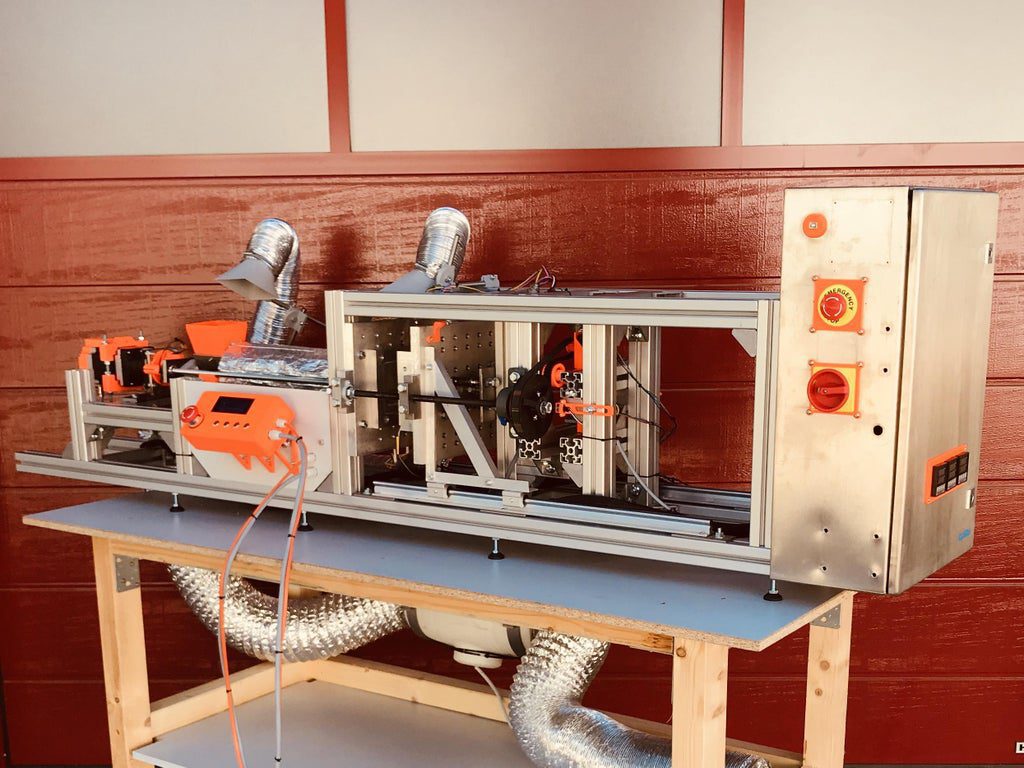

Homemade recycling rig turns plastic waste into new products

Reading Time: 2 minutesHomemade recycling rig turns plastic waste into new products Arduino Team — November 24th, 2020 While that plastic cup, bag, dish, or other item may have served its purpose, more than likely it could be formed into something new. With this in mind, the SOTOP-Recycling team of Manuel Maeder, Benjamin Krause, and…

-

Classify your trash with Raspberry Pi

Reading Time: 3 minutesMaker Jen Fox took to hackster.io to share a Raspberry Pi–powered trash classifier that tells you whether the trash in your hand is recyclable, compostable, or just straight-up garbage. Jen reckons this project is beginner-friendly, as you don’t need any code to train the machine learning model, just a little to load…

-

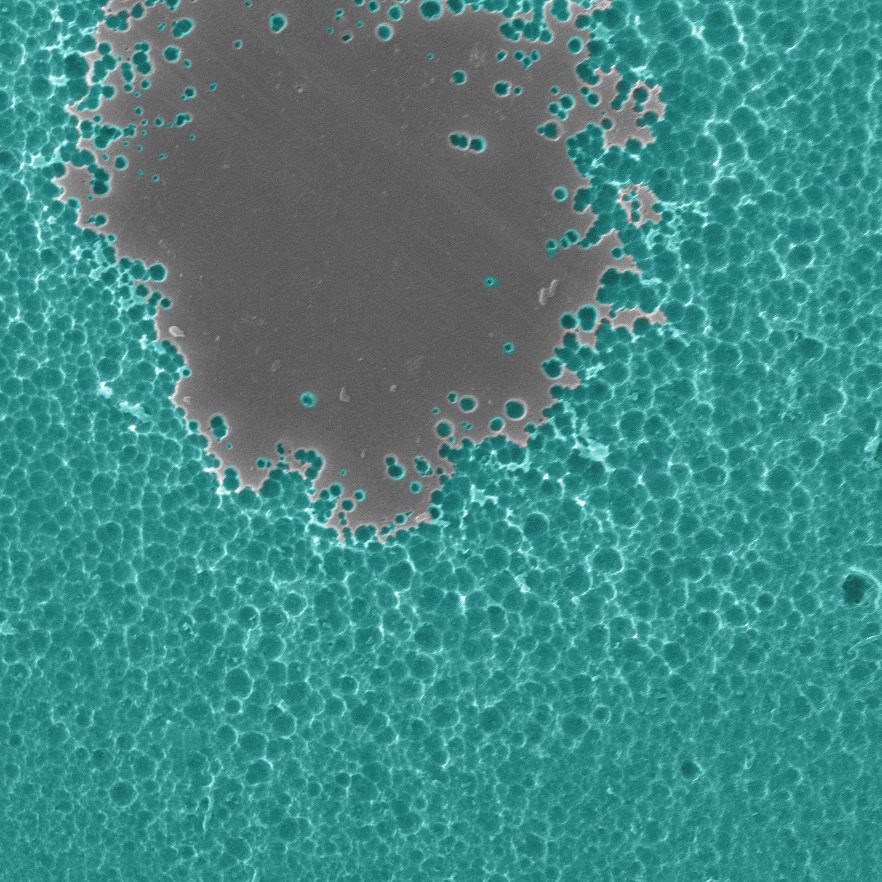

Scientists Accidentally Create Mutant Enzyme that Eats Plastic

Reading Time: 3 minutesIn what could be a major ecological breakthrough, scientists have accidentally invented a mutant enzyme that likes to feast on PET plastic. We love 3D printing, but it’s sometimes hard to reconcile the joy of fabricating a 3D object with the plastic waste that is generated. Trial and error is the nature…

-

US Army is Recycling Plastic Bottles for 3D Printing

Reading Time: 3 minutesThe US Army is exploring ways to convert discarded plastic bottles into recycled PET filament. Soldiers will become even more self-sufficient in the battlefield by 3D printing useful spare parts from waste material. A collaboration between the US Army Research Laboratory and the US Marine Corps has resulted in the discovery of…

-

DIY Fairy House That I Made From Trash

Reading Time: 3 minutesHi, in this tutorial I show you how I made a fairy house lamp recycling some cardboard from an old box, egg cartons, pizza boxes, toilet paper tubes and two plastic bottles. The only bought materials I used are the acrylic colors, the hot glue and the P.V.A. glue (less than 3$…

-

“I’ve Been Making Dresses From Wrapping Paper After The Holidays For A Few Years”

Reading Time: 3 minutesFew things are more thrilling than ripping open a Christmas present, but the shiny wrapping paper that gets thrown away afterward usually goes straight to the landfill. North Carolinian costume designer Olivia Mears, known on social media as avantgeek, has come up with a brilliant way to reuse those picked-over packages –…

-

I Upcycle Old Louis Vuitton Bags Into Star Wars Sculptures

Reading Time: 3 minutesMy name is Gabriel Dishaw, my passion for working with metal and mechanical objects has been essential in the evolution of my art. It provides me an avenue to express myself in a way that brings new life to materials such as typewriters, adding machines and old computers – technology that would…

-

I’ve Made Some Whimsical Winter Scenes From Old Snow Shovels

Reading Time: 3 minutesI’ve been working with old rusty tools for a couple of years now and love giving these discarded items a new life. I use a plasma torch and hand cut custom designs into old tools. Some items will have other parts welded on as well. Most of my work involves saws, but…