Schlagwort: medical 3D printing

-

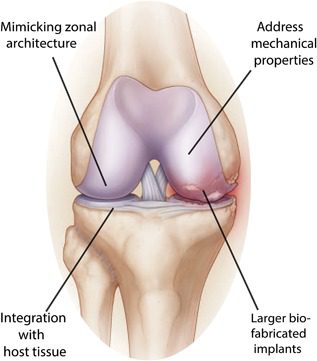

3D Printing Living Tissue Could Heal Damaged Joints and Eliminate Arthritis

Reading Time: 3 minutesA team of researchers from the University Medical Centre Utrecht in the Netherlands have created a biofabrication method to create living tissues that replicate cartilage and could potentially be implanted to repair damaged joints. Experienced by millions and millions across the world, arthritis is a physical disability that nearly one in ten…

-

Engineers Develop 3D Printing Method That Produces Tissue Scaffolding From Sugar

Reading Time: 4 minutesA team of engineers from the University of Illinois have developed a free-form isomalt 3D printing technology that produces intricate sugar-based scaffolding, which could potentially be used to grow tissue or study tumors. Slowly but surely, bioprinting is reshaping the medical landscape in multiple ways, from producing custom scaffolding to quite literally…

-

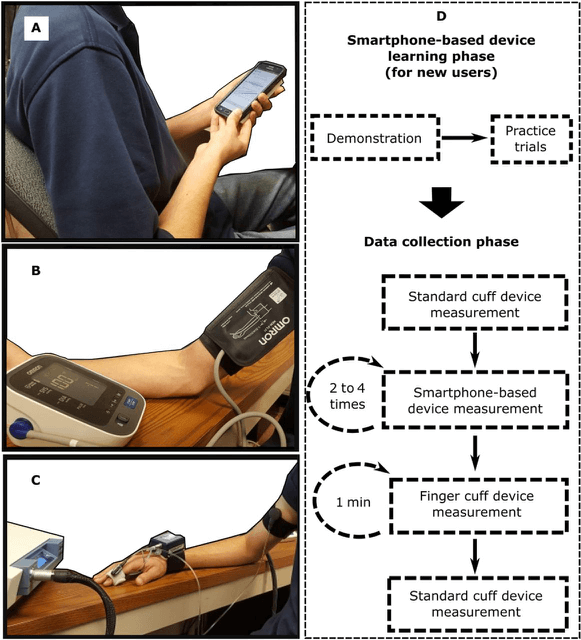

3D Printed Smartphone Device Puts Blood Pressure Monitoring at Your Fingertips

Reading Time: 3 minutesResearchers from Michigan State University have developed 3D printed smartphone device that is able to monitor the user’s blood pressure. The device uses a sensor that calculates blood pressure at the touch of a fingertip. A team of researchers from Michigan State University have developed a 3D printed smartphone device that enables people…

-

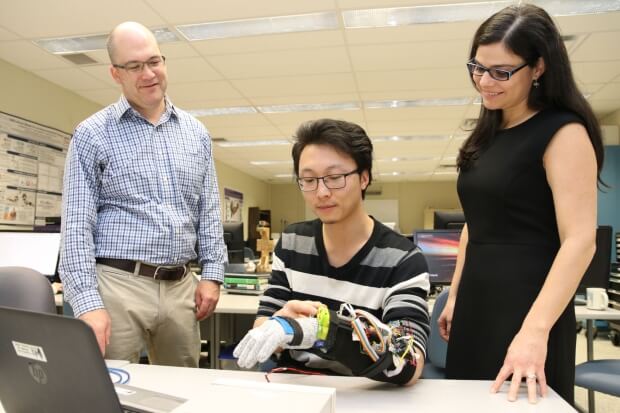

Researchers 3D Print Tremor Suppression Glove to Help Parkinson’s Patients

Reading Time: 3 minutesResearchers from Western University have developed a functional prototype of a new tremor suppression glove. This device aims to provide more independence to patients suffering from Parkinson’s Disease. Across the world, there are around 10 million people with Parkinson’s disease, a neurodegenerative disorder that causes a loss of dopaminergic neurons in the area…

-

KWSP to Launch ‘While You Wait’ 3D Printing Service for Custom Insoles

Reading Time: 3 minutesKW Special Projects is teaming up with the advanced foot orthotics manufacturer Podfo Ltd to launch a ‘while you wait’ 3D printing service for customized insoles. KW Special Projects (KWSP), the engineering solutions provider based in the UK, has begun work on a £750,000 project to develop a ‘while you wait’ service…

-

Researchers 3D Print Accurate Microfluidic Model of the Blood-Brain Barrier

Reading Time: 3 minutesItalian researchers have developed 3D bio-hybrid microfluidic models to screen for drugs and assess toxicity of nanoparticles crossing the blood-brain barrier. The primary function of the blood-brain barrier is to protect the brain from neurotoxic compounds, pathogensand , blood-circulating compounds. In order to develop new treatments for neurodegenerative disease and brain disorders,…

-

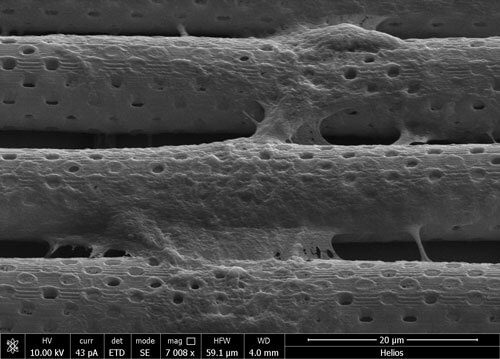

3D Printed Ceramic Implant Fuses With Bone to Repair Broken Limbs

Reading Time: 2 minutesResearchers from the University of Sidney have developed a 3D printed ceramic implant that fuses with natural bone. The implant was successfully used to repair large leg fractures in sheep. As most of us know, breaking a bone is never an enjoyable experience, and having a metal plate or screws inserted into…