A team of engineers from the University of Illinois have developed a free-form isomalt 3D printing technology that produces intricate sugar-based scaffolding, which could potentially be used to grow tissue or study tumors.

Slowly but surely, bioprinting is reshaping the medical landscape in multiple ways, from producing custom scaffolding to quite literally growing organs from stem cells. And now, after this latest development, 3D printing has just become a viable tool to produce intricate scaffolding structures out of sugar. That’s right, sugar…

An engineering team at the University of Illinois has developed a 3D printer that can produce thinly layered networks of isomalt – the sugar alcohol used to make throat lozenges.

The research entails materials and mechanics of free-form isomalt printing, which is a technique where the nozzle travels through space while the dissolved material solidifies. While other types of sugar are prone to burning or crystalizing when 3D printed, the sugar alcohol isomalt works much more efficient for this process.

Matthew Gelber, the first author on the corresponding research paper, believes that the 3D printer could be used design structures such as cells and tissues eventually. However, growing tissues is just one application of the new technology, and there are other commercial applications in the team’s sights.

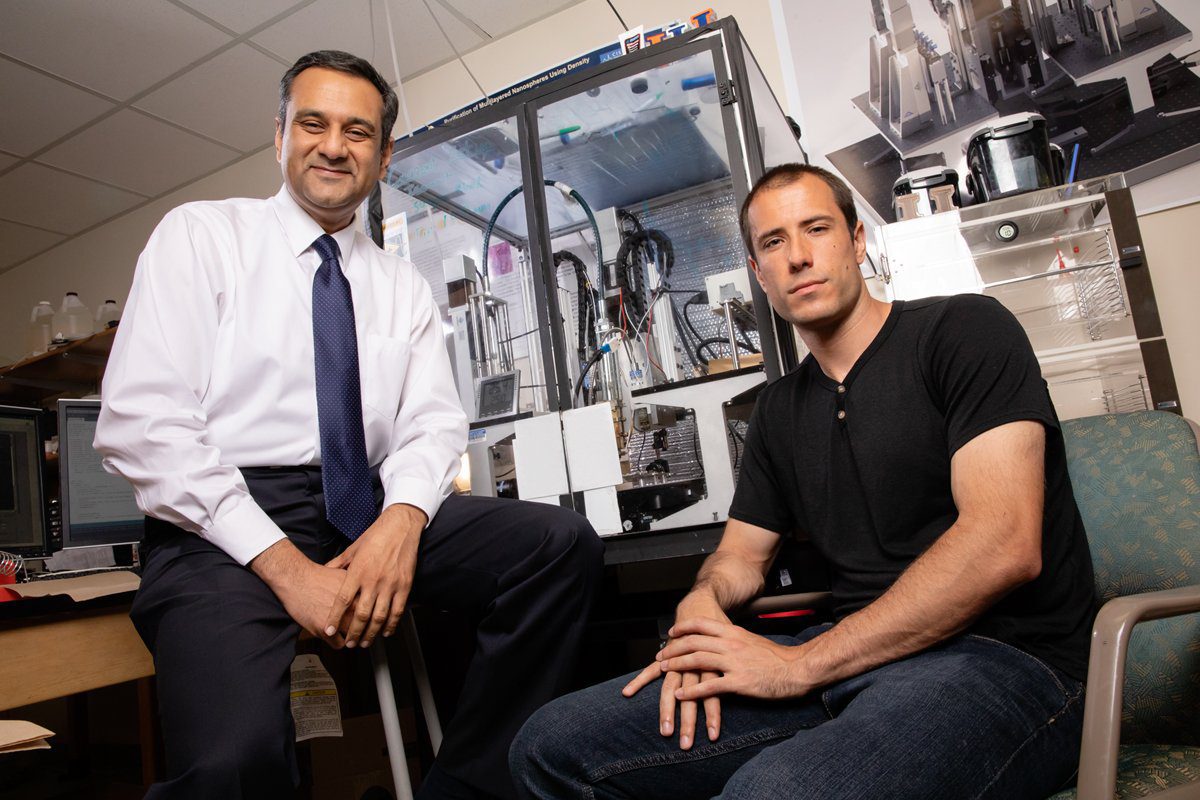

Professor Rohit Bhargava (left) and PhD Matthew Gelber (right) who developed the free-form 3D printer. (Image: L. Brian Stauffer)

3D Printing Sugar Creates Cylinder Tubes and Tunnels

Called free-form isomalt printing, the technique uses a nozzle that travels freely through space solidifying dissolved materials. Gelber explains:

Professor Rohit Bhargava at the Cancer Center at Illinois describes that the primary advantage of free-form structures is their ability to produce thin tubes that include circular cross-sections. This has previously not been achievable with polymers. The dissolved sugar on the other hand creates cylinder tubes and tunnels that resemble blood vessels.

In order to create optimized design scaffolds and map out printing pathways, the researchers collaborated with Greg Hurst at Wolfram Research on an algorithm. These free-form structures are able to be made into thin tubes with circular cross-sections without the need for support structures. Once the sugar is dissolved, there’s a series of connected cylindrical tubes that resemble blood vessels, making it possible to transport nutrients in tissue or to create channels in microfluidic devices

On top of that, the system also allows for more accurate control over the mechanical properties of each part. Bhargava explains:

Needless to say, this recent development from the University of Illinois could be a game-changer in the medical landscape, presenting various possible applications, such as developing scaffolding to grow tissue of study tumors.

The final paper, entitled “Model-guided design and characterization of a high-precision 3D printing process for carbohydrate glass,” has recently been published in Additive Manufacturing.

3D printed bunny using the technology. (Image: Troy Comi)

Source: Tech Explorist

Website: LINK