Schlagwort: kickstarter

-

3D Print a Custom Smartphone with Kite on Kickstarter

Reading Time: 2 minutesIn a new crowdfunding project on Kickstarter, Hyderabad-based iSquare Mobility has developed a module called Kiteboard for building a modular Android smartphone. Now the concept of a modular smartphone is nothing new; efforts by companies as diverse as Jolla, LG, Fairphone and Motorola were bought to market with varying degrees of success. But the…

-

Floss All Your Teeth at Once with the Custom-Fitted and 3D Printed UFloss

Reading Time: 3 minutesA new Kickstarter campaign has been launched for a new 3D printed flossing device called UFloss, which allows you to floss all of your teeth at the same time. This oral hygiene product will use an app to take impressions of the user’s mouth, creating a fully custom-fitted solution for all. As both…

-

3D Printed Custom Fit In-Ear Monitors on Kickstarter

Reading Time: 3 minutesProfessional musicians and audiophiles may soon be able to benefit from custom-fit, 3D printed in-ear monitors, if this Kickstarter campaign by HW Audio is successful. HW Audio are a British company that specializes in making custom in-ear monitors for musicians and audiophiles. Now they’ve turned to Kickstarter to raise funds for a…

-

The Tungsten Carbide Nozzle Now 170% Funded on Kickstarter

Reading Time: 5 minutesIn March, Montreal-based Dyze Design launched the Tungsten Carbide nozzle on Kickstarter. A state of the art 3D printing accessory, the nozzle offers high wear resistance and performance for almost any 3D printer. Fully funded and then some, it’s not too late to get in on Early Bird pledges. In March, Montreal-based…

-

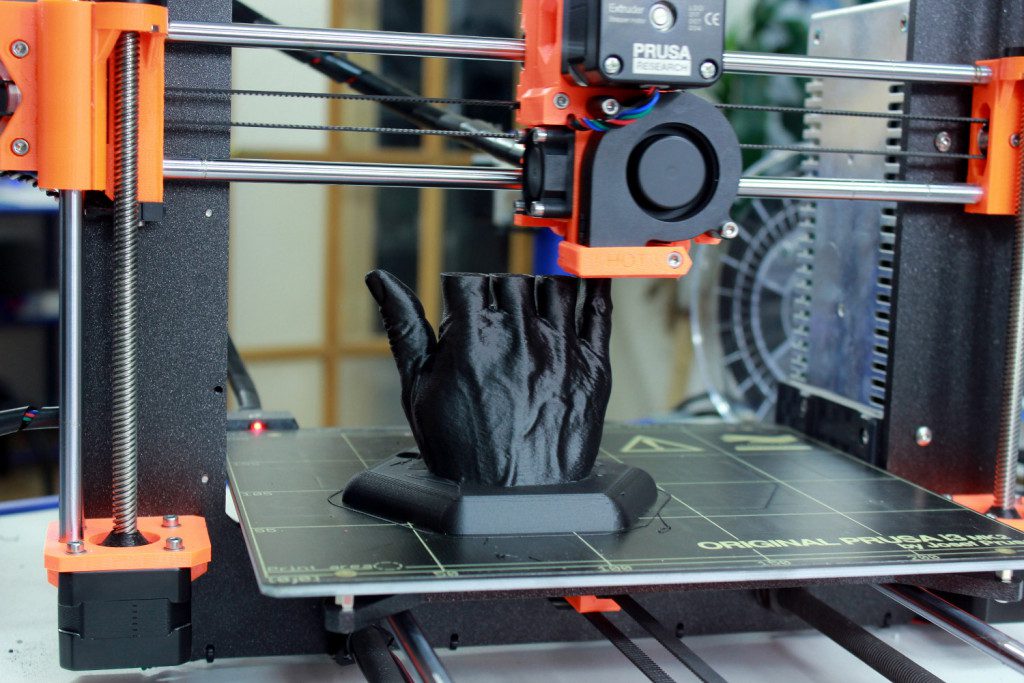

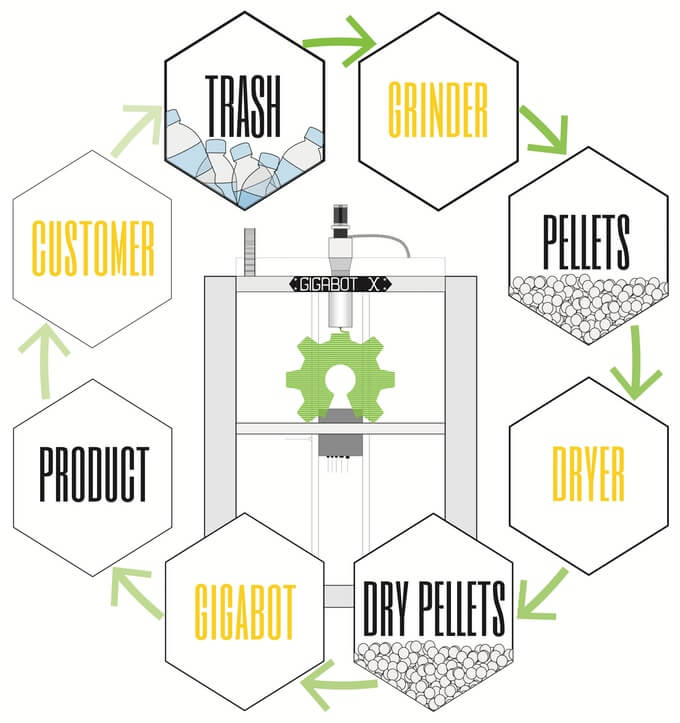

Gigabot X can 3D Print with Recycled Plastic Pellets

Reading Time: 3 minutesNow live on Kickstarter is the Gigabot X, a large-scale, direct pellet extrusion 3D printer for fabricating with recycled plastic. Houston, Texas might seem likely an unlikely location for a revolution in 3D printing, but this is where re:3d have announced the Gigabot X, an open source 3D printer that fabricates with…

-

12 Kickstarter 3D Printer Projects Live Right Now

Reading Time: < 1 minutePitch: “High-quality PLA filament featuring the patented Furling SLIDER, which prevents your filament from getting tangled-up!” Comments on this Kickstarter 3D Printer Project: Utilising an in-house production system, these campaigners want to develop a full rainbow spectrum of 3D printing PLA filament that’s easy on the wallet. They’ve also devised a…

-

3-in-1 Snapmaker 3D Printer: Review the Facts Here!

Reading Time: < 1 minuteThe concept of the Snapmaker 3D printer is a modular machine with three distinct functions. The intended audience is the workshopper pushed for space. First and foremost, the Snapmaker is an all-metal 3D printer. The aluminum frame encases all wiring, with the exception of a few tidy ribbon cables. But the…

-

Raise3D N2 3D Printer: Review the Facts Here!

Reading Time: 2 minutesThe Raise3D N2 Plus has a huge build volume of 12″ x 12″ x 12″. Additionally, the entire printer is fully enclosed with a sturdy aluminum metal frame and ABS, acrylic, and poly-carbonate casing. The fully enclosed design not only improves print quality when printing with materials such as ABS, but also…

-

11 Kickstarter 3D Printer Projects Live Right Now

Reading Time: < 1 minutePitch: “Robust, precise and user-friendly upgrade for your desktop 3D printer that lets you print ceramics, porcelain and pastes.” Comments on this Kickstarter 3D Printer Project: This project is a user-friendly add-on for your desktop 3D printer so that you can fabricate objects in ceramics and porcelain. The campaigners reckon that…

-

10 Kickstarter 3D Printer Projects Live Right Now

Reading Time: < 1 minutePitch: “Unfortunately SLA machines are complicated, bulky and very expensive. We have been working to change this since 2015. We designed PLUTO to be easy to use and compact, really fitting on anybody’s desktop. From the first moment we kept in mind that PLUTO should remain affordable for everyone.” Comments on this…

-

‚All Walls Must Fall‘ Successfully Completes Its Kickstarter Campaign

Reading Time: < 1 minute“We’re totally overwhelmed by the support of our generous backers,” said Jan David Hassel, Designer at inbetweengames. “The Kickstarter went way over what any of us could have reasonably expected or hoped for. Now the real fun, not to mention hard work, begins as we deliver on the turning the Kickstarter…

-

-

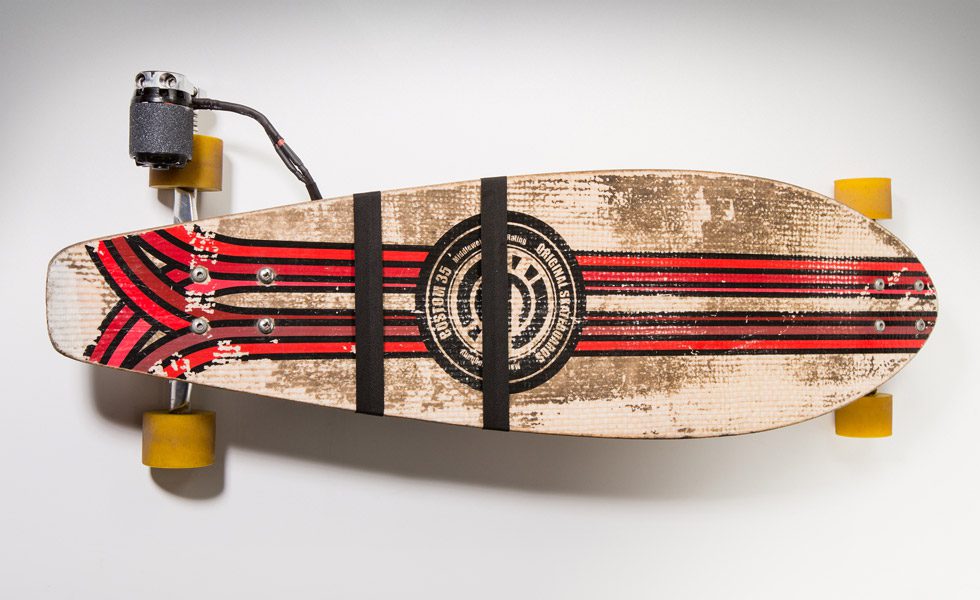

Kickr – Electric Motor for any Longboard

Reading Time: < 1 minuteWhy spend $1,000+ on a boosted board, when you could just pick up a Kickr, which is basically a modular, patent-pending, precision-machined, non-obtrusive electric drivetrain that is compatible with almost any board. There’s no re-drilling decks, changing trucks or even wheels, and it will work with your board to preserve the…

-

Ktrak winter mountain bike, Best Transformation Kit Yet!

Reading Time: < 1 minuteForget skis, bring your mountain bike and a KtraK kit to the slopes this winter. With a ski that replaces the front wheel and a rear traction system mounting over the rear tire, your bike instantly becomes a human-powered snowmobile. [mbYTPlayer url=“https://www.youtube.com/watch?v=LZHNLIXWpNw“ opacity=“.5″ quality=“medium“ ratio=“auto“ isinline=“false“ showcontrols=“false“ realfullscreen=“true“ printurl=“true“ autoplay=“true“ mute=“true“…