Schlagwort: Filament

-

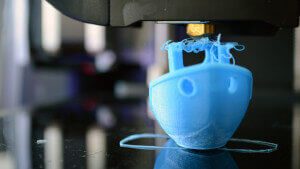

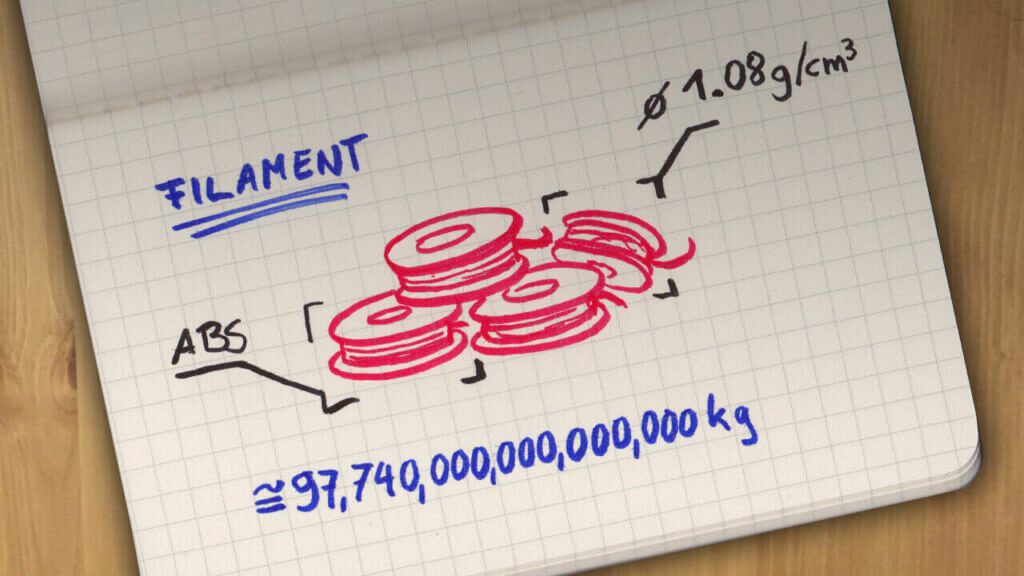

What Would it Take to 3D Print a 1:1 Scale Death Star?

Reading Time: 4 minutesA 3D printed Death Star in its original size and glory – that’s a 3D printing project of galactic proportions. Franklin Houser has crunched the numbers. So, what does it take to 3D print a 1:1 scale Death Star? The question I have asked myself depends on several variables. For simplicity, I will…

-

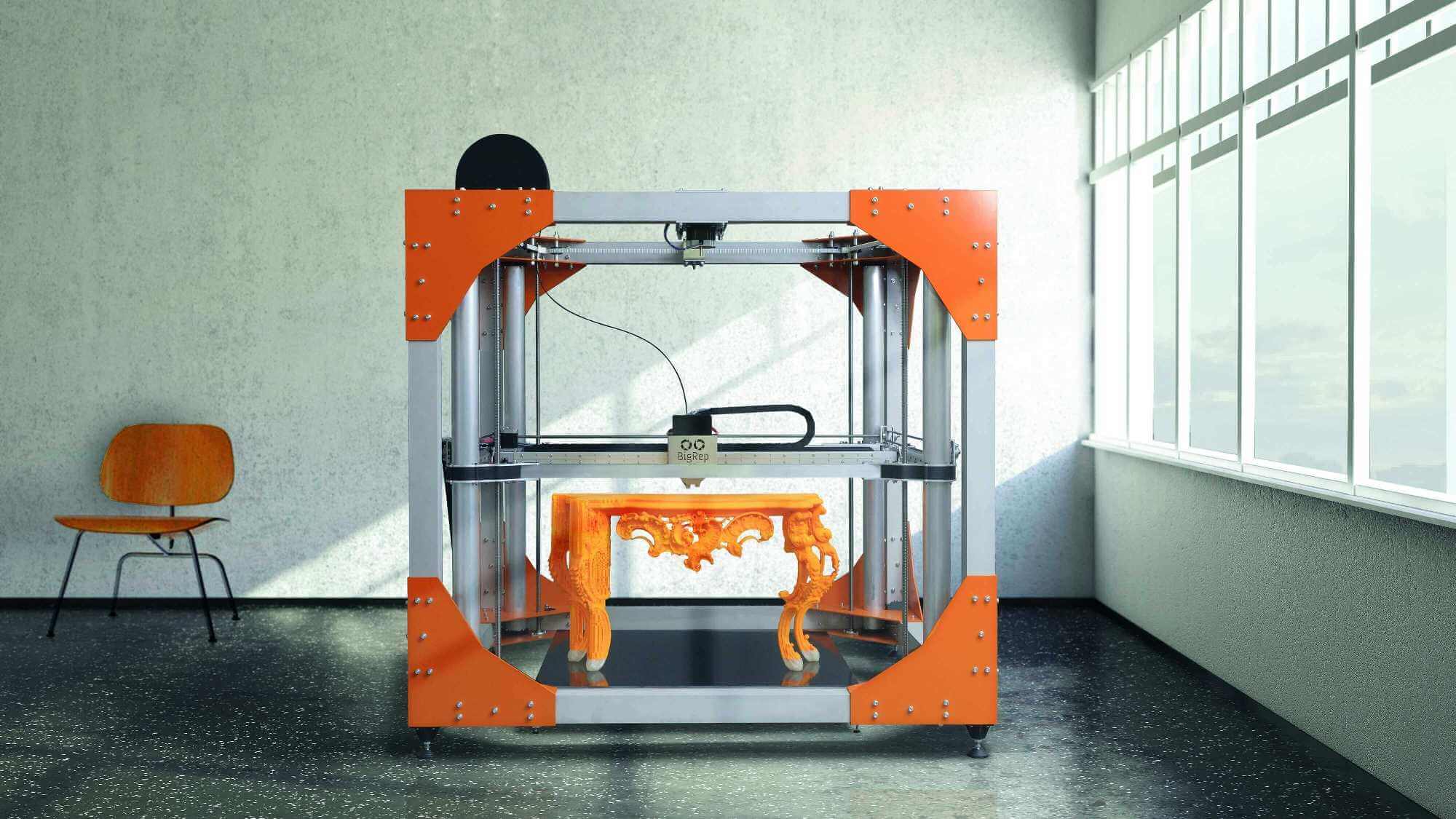

BigRep Launches New Pro Flex Filament for 3D Printing

Reading Time: 3 minutesThe new Pro Flex filament is a world first for the large-scale FDM industry, according to 3D printer manufacturer BigRep. BigRep is a large-scale FDM 3D printer manufacturer based in Berlin, and today they announce a new “innovation” in filaments that many users of standard desktop printers may find rather quaint. It’s…

-

![[FLASH DEAL] New Matter Filament, 63 -75% Off at $7.49](data:image/svg+xml;charset=utf-8,%3Csvg xmlns%3D'http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg' viewBox%3D'0 0 944 532'%2F%3E)

[FLASH DEAL] New Matter Filament, 63 -75% Off at $7.49

Reading Time: < 1 minuteSad news this week with the closure of 3D printer manufacturer New Matter. Ahead of shuttering some time this summer, the company is clearing house with a fire sale of all its products, including filament. It never a nice thing to see a company that puts real, tangible 3D printing products…

-

3D Printing Troubleshooting: 34 Common 3D Printing Problems

Reading Time: < 1 minute[unable to retrieve full-text content]Website: LINK

![[FLASH DEAL] New Matter Filament, 63 -75% Off at $7.49](https://www.blogdot.tv/wp-content/uploads/2018/02/flash-deal-new-matter-filament-63-75-off-at-7-49.jpg)