Schlagwort: Desktop Metal

-

Markforged Cleared of Desktop Metal IP Infringement Claims

Reading Time: 15 minutesIn March, Desktop Metal filed a lawsuit against Markforged for allegedly copying portions of its patented metal 3D printing processes. Last week, a federal jury decided to clear Markforged of both IP infringement allegations, marking a major victory for the defendant. UPDATE (7/30/18) – Court Clears Markforged of IP Infringement Accusations Earlier this…

-

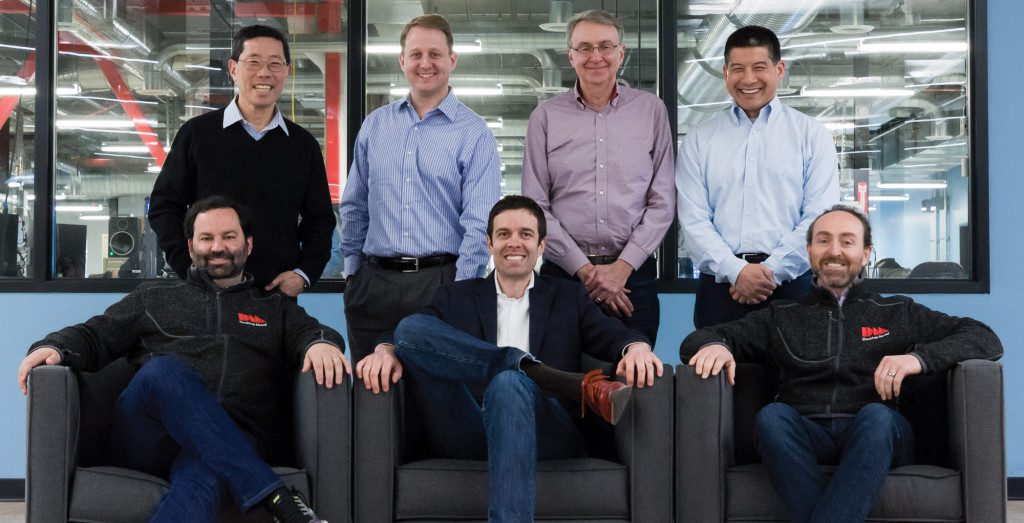

All3DP Heads North to Visit the Metal 3D Printing Pioneers at Desktop Metal

Reading Time: 9 minutesWe recently had the pleasure of paying a visit to the Massachusetts-based headquarters of Desktop Metal, the pioneering 3D printing company that is making affordable metal 3D printing a reality. Check out our in-depth tour of the facilities and exclusive interview with co-founder Jonah Myerberg. When one thinks of Boston, one typically…

-

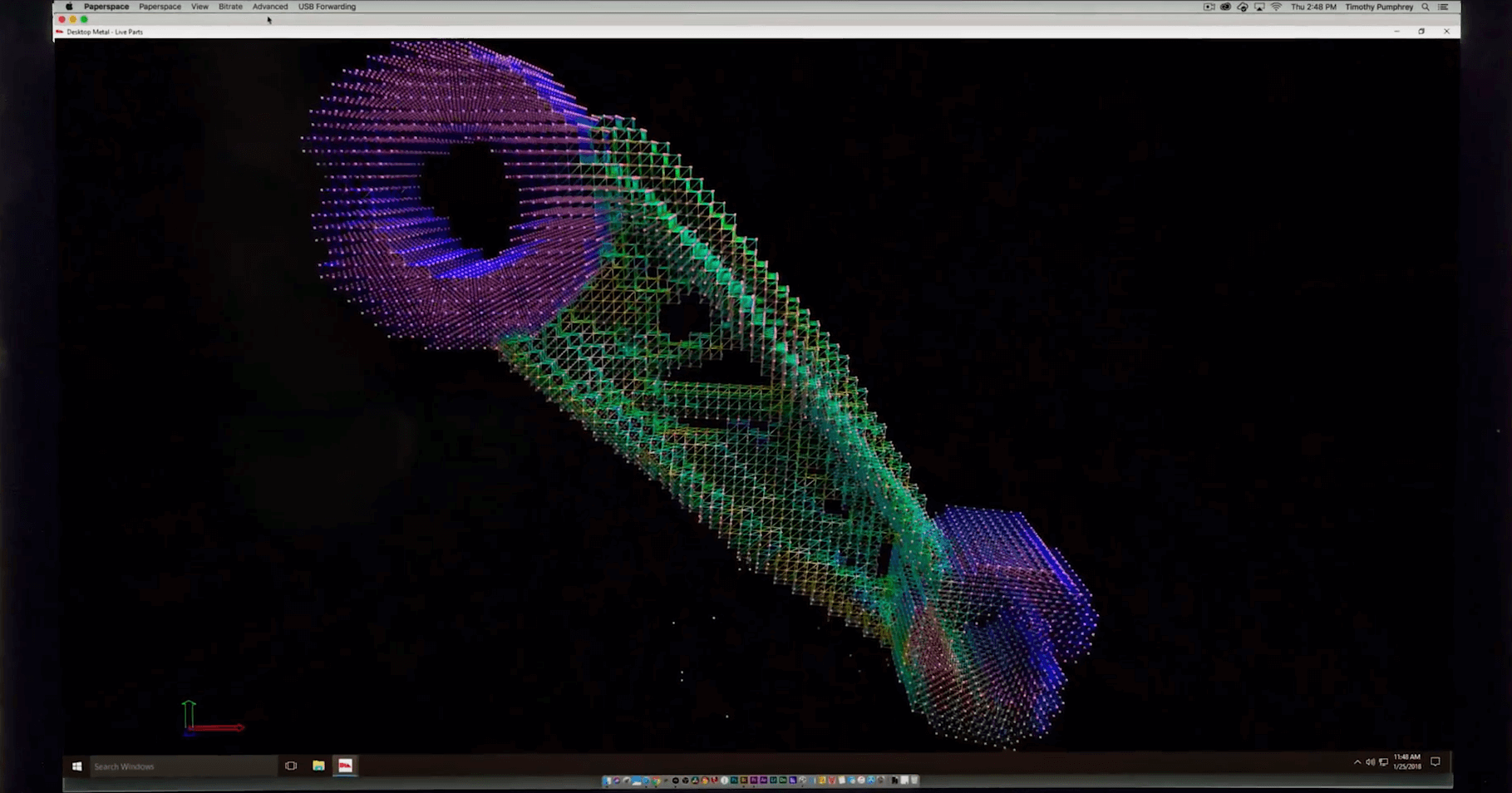

Desktop Metal Unveils Live Parts Generative Design Tool for SOLIDWORKS

Reading Time: 3 minutesDesktop Metal is partnering with Dassault Systèmes to develop Live Parts, a new generative design tool. This experimental technology is exclusive to SOLIDWORKS users, and aims to simplify generative design for 3D printing. This week in Los Angeles, some of the most innovative names in 3D printing and CAD software have joined together…

-

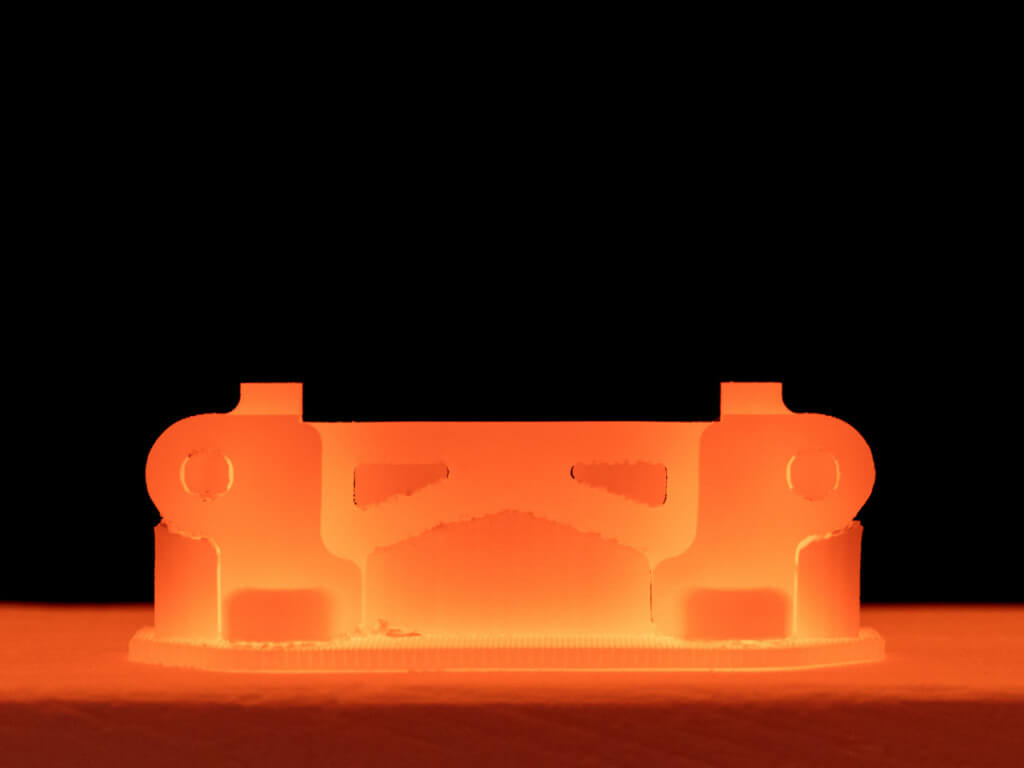

Desktop Metal Gets Patents for Metal 3D Printing Supports System

Reading Time: 3 minutesForging a new path for more accessible metal 3D printing, Desktop Metal has been granted patents for its Separable Supports technology. Designed to make metal 3D printing more accessible and safer, the tech means multi-material metal printing and hand-removable supports. Desktop Metal, a Massachusetts-based company that has developed office and mass-production level…