Schlagwort: CNC

-

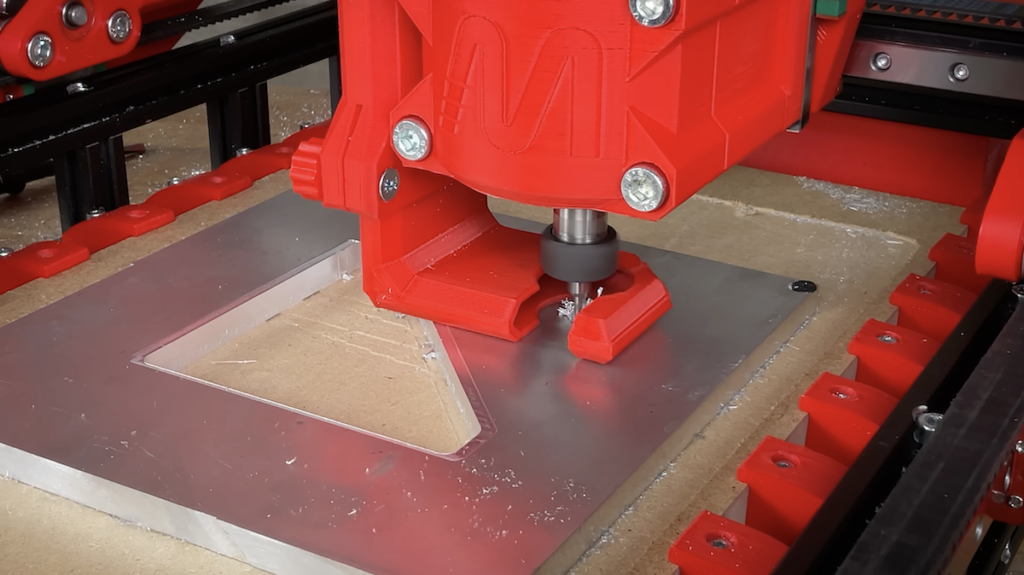

A 3D-printed CNC mill made from scratch

Reading Time: 2 minutesArduino Team — July 20th, 2022 CNC machines (both CNC mills and CNC routers) are very useful to makers. With them, you can fabricate custom wood, plastic, or metal parts to the exact dimensions that you define in a CAD (computer-aided design) model. But CNC routers are expensive and CNC mills capable…

-

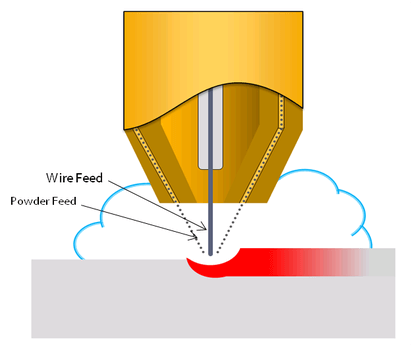

Arduino-controlled CNC engraver uses solar power

Reading Time: 2 minutesArduino Team — April 28th, 2022 Usually when we use the term “solar power,” we are referring to indirect energy use: photovoltaic solar panels collect energy from the sun and then either pass it along to a device or store it for later use. But some systems can use power from the…

-

This massive five-axis CNC machine is 3D-printable

Reading Time: 2 minutesArduino Team — August 4th, 2021 CNC (Computer Numerical Control) mills, routers, and lathes are indispensable manufacturing tools. If you need a part that adheres to tight tolerances, you turn to a CNC machine. Industrial CNC equipment is usually large, heavy, and very expensive. But small models exist for light-duty hobby jobs.…

-

The P-CNC Plotter is a DIY drawing machine ‘disguised as a quadruped robot’

Reading Time: 2 minutesThe P-CNC Plotter is a DIY drawing machine ‘disguised as a quadruped robot’ Arduino Team — July 27th, 2021 In their quest to create a portable CNC plotter, Instructables user tuenhidiy combined several PVC pieces with a couple of motors to build the P-CNC Plotter. The small machine — which was designed to resemble a…

-

This may be one of the cheapest and easiest CNC drawing machines you’ll find

Reading Time: 2 minutesThis may be one of the cheapest and easiest CNC drawing machines you’ll find Arduino Team — July 15th, 2021 CNC plotters are a lot of fun to build and use, as they teach mechanics, electronics, and how G-code works. However, traditional Cartesian machines often require expensive components such as linear rods…

-

Two Arduinos are used to control this DIY three-axis CNC plottee

Reading Time: < 1 minuteArduino Team — June 23rd, 2021 We’ve seen a number of homemade CNC machines throughout the years, but Tuenhidiy’s build — made from some discarded materials — is no less impressive. This unique CNC plotter features a frame cleverly constructed out of two wooden wine boxes, which appear to be the…

-

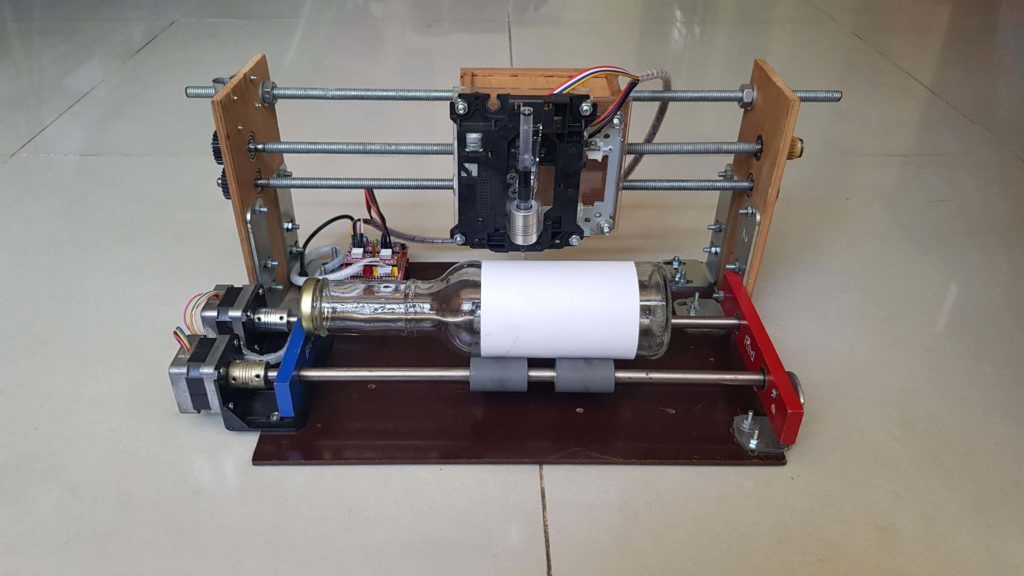

Draw on bottles using a CNC plotter made from old printer rollers and other scraps

Reading Time: 2 minutesDraw on bottles using a CNC plotter made from old printer rollers and other scraps Arduino Team — November 12th, 2020 To label used bottles that would otherwise go to waste, “tuenhidiy” created a CNC plotter that itself consists mostly of scraps! The machine’s X and Z axes are formed out of…

-

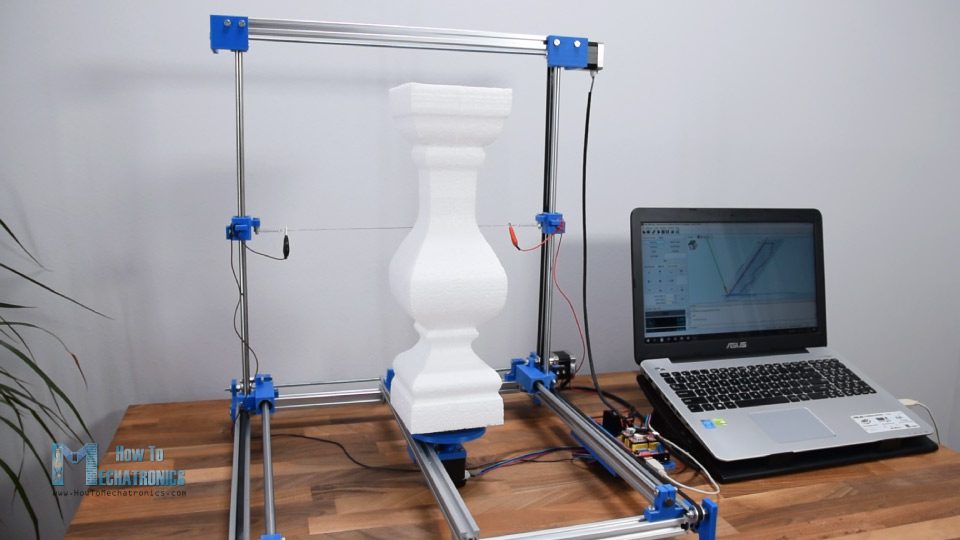

CNC hot wire cutter moves with four axes

Reading Time: 2 minutesCNC hot wire cutter moves with four axes Arduino Team — May 14th, 2020 When working with Styrofoam, a conventional CNC machine like a router or laser cutter just won’t do. However, as shown in Michael Rechtin’s excellent video below, a hot wire can carve foam like butter, creating custom wings for…

-

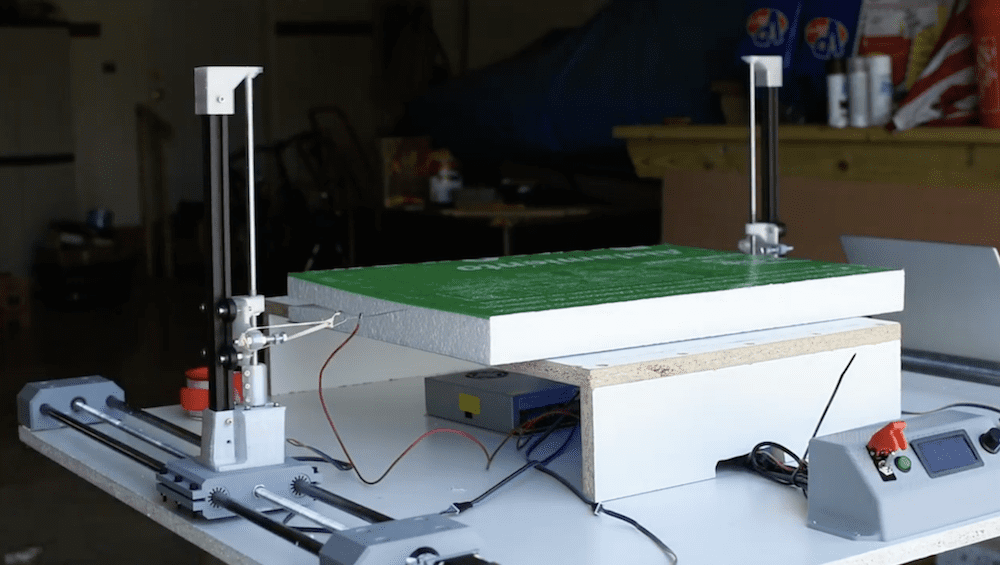

Carve 2.5D shapes out of foam with this Arduino-controlled hot wire cutter

Reading Time: 2 minutesCarve 2.5D shapes out of foam with this Arduino-controlled hot wire cutter Arduino Team — February 8th, 2020 You may have a 3D printer or other “digital” tools like a laser engraver or CNC router, but what if you want to work with Styrofoam? As How To Mechatronics demonstrates in his latest…

-

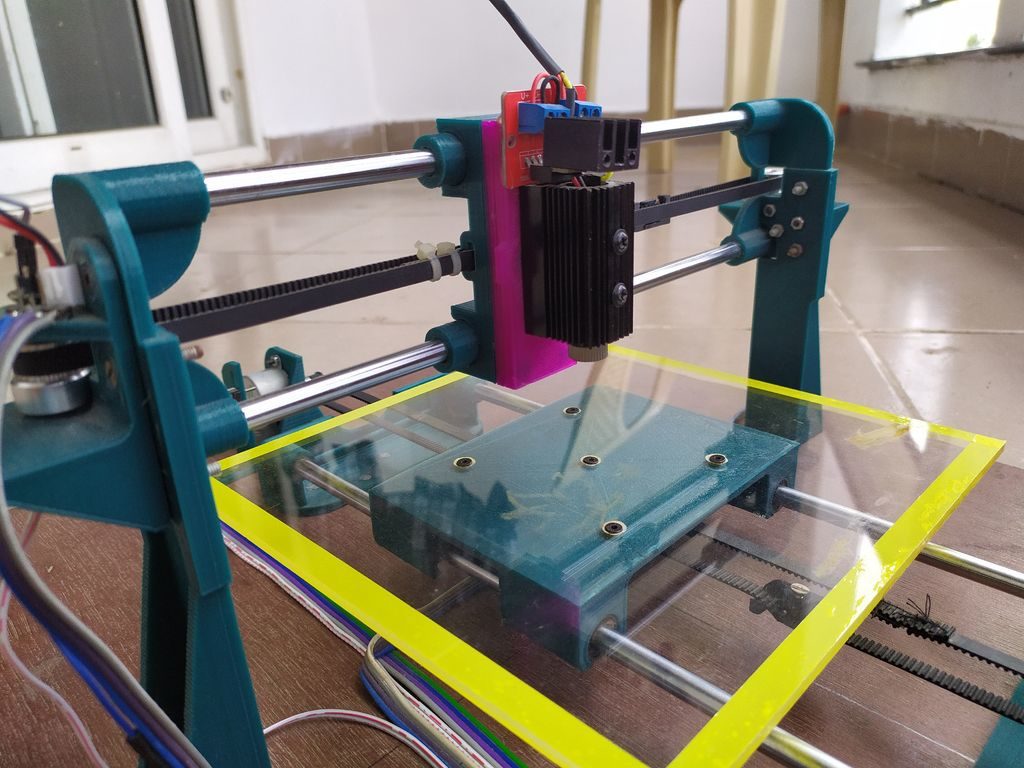

Pen plotter? Laser engraver? This DIY machine gives you both!

Reading Time: 2 minutesPen plotter? Laser engraver? This DIY machine gives you both! Arduino Team — October 30th, 2019 If you find yourself debating between a pen plotter or laser engraver, this project by Patrick Panikulam lets you have the best of both worlds in style. The DIY device pulls a writing instrument in the…

-

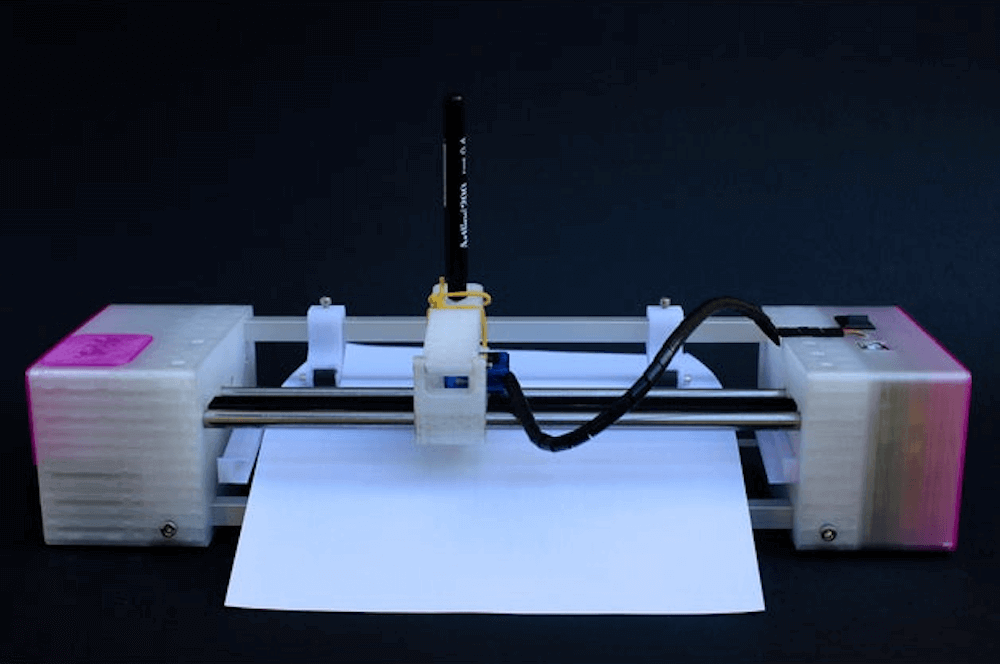

d.i.d. is a scalable 3D-printed pen plotter

Reading Time: 2 minutesd.i.d. is a scalable 3D-printed pen plotter Arduino Team — August 29th, 2019 While computer printers are readily available, if you’d like a plotting device that drags a pen, marker, or whatever you need across paper to create images, your options are more limited. To fill this gap, studioprogettiperduti has come up…

-

Reviving an old CNC router with Arduino

Reading Time: 2 minutesReviving an old CNC router with Arduino Arduino Team — August 12th, 2019 Makerspace i3Detroit was the recent recipient of a free yet non-functioning CNC router. While out of commission when received, the device’s mechanical components and motors appeared to be in operational condition, plus it had a large work surface. The…

-

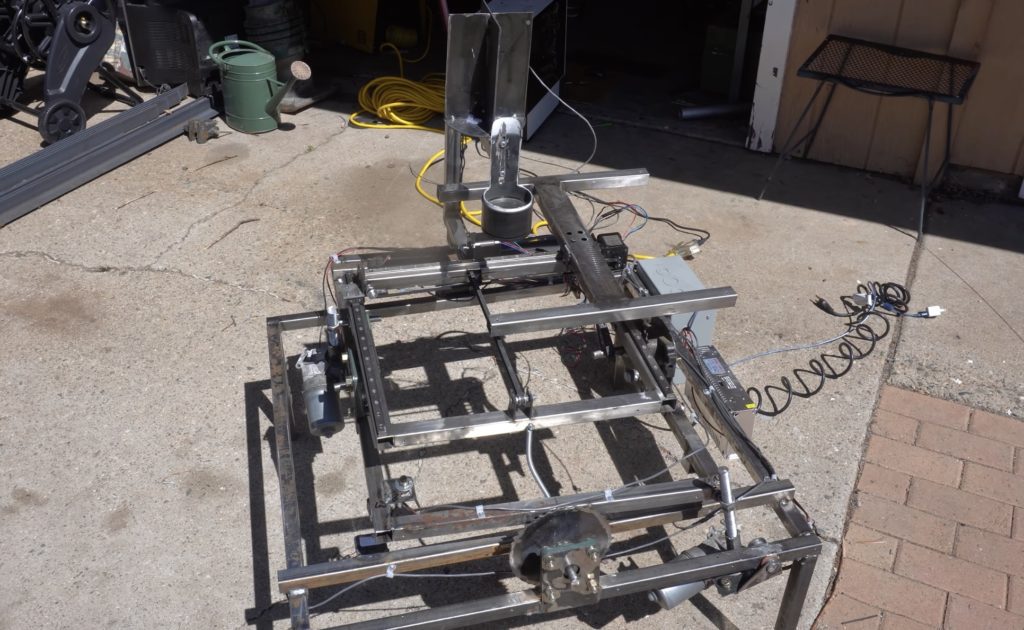

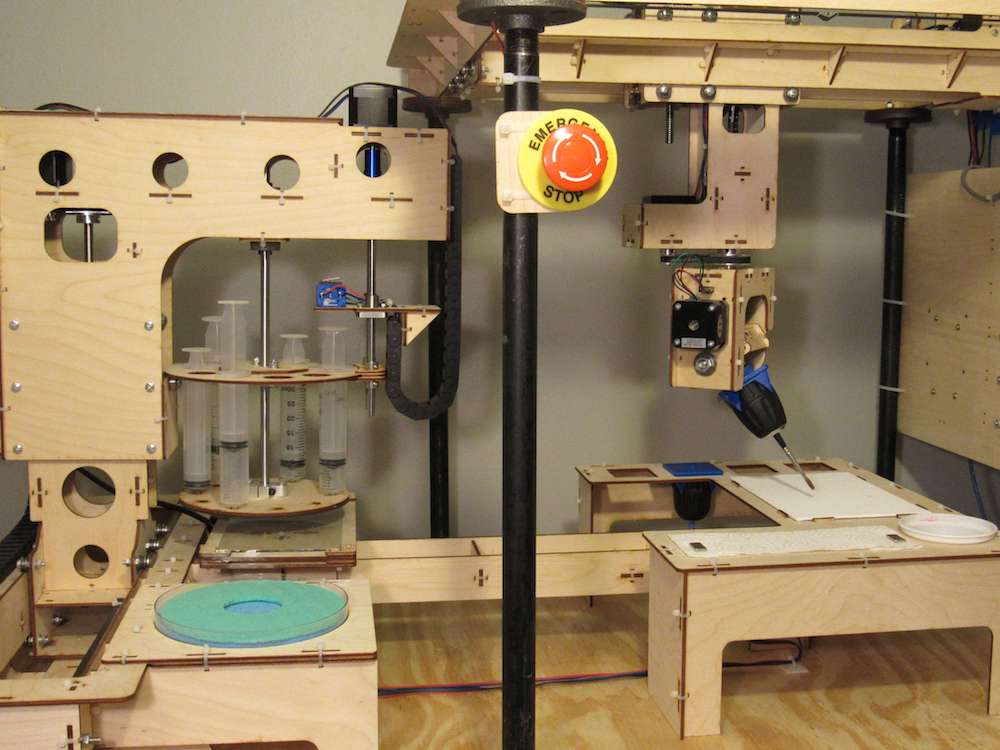

If Then Paint is a six-axis CNC painting machine

Reading Time: 2 minutesIf Then Paint is a six-axis CNC painting machine Arduino Team — July 29th, 2019 It’s easy to see that painting takes a lot of skill, but few really understand how much skill is involved like John Opsahl, who created the “If Then Paint” CNC canvas painting machine. In order to produce the…

-

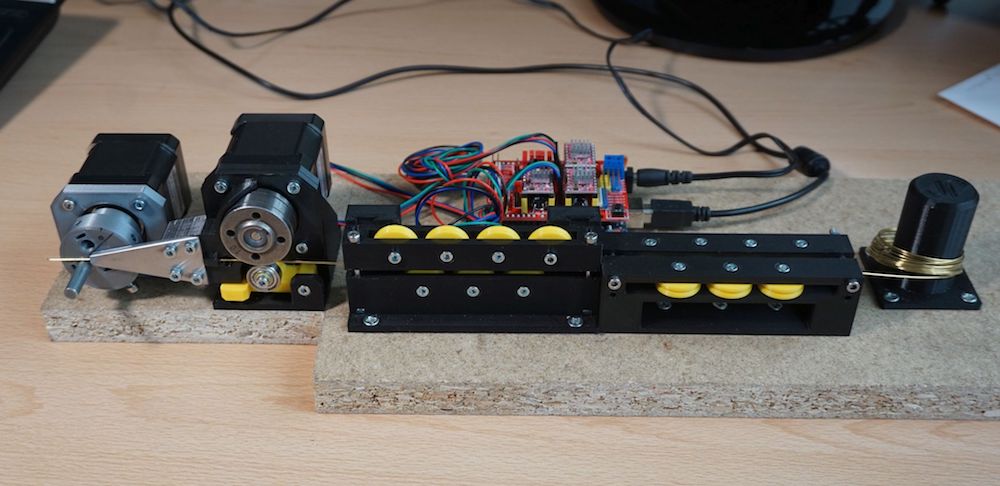

This machine bends brass wire with precision

Reading Time: < 1 minuteThis machine bends brass wire with precision Arduino Team — July 22nd, 2019 Jiri Praus enjoys using brass wire for his freeform sculptures, but isn’t a fan of making the same bends over again. To solve this problem, he designed a CNC machine to handle that task for him. His device…

-

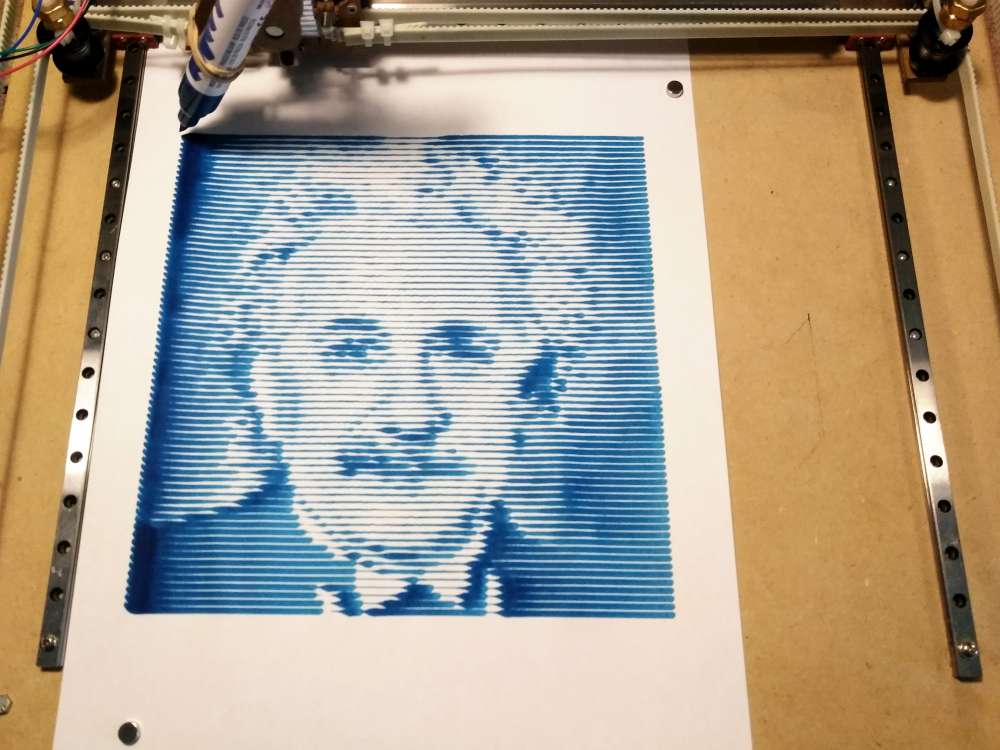

Facere-Bot is a portable machine that draws iconic photos

Reading Time: < 1 minuteFacere-Bot is a portable machine that draws iconic photos Arduino Team — July 10th, 2019 Inventor Artist Darcy Whyte wanted a drawing robot that was light enough to carry around, and could quickly produce drawings. Naturally, he turned to an Arduino Uno, along with a CNC shield and a trio of…

-

Cycloid-O-Matic creates spirograph-like patterns

Reading Time: < 1 minuteCycloid-O-Matic creates spirograph-like patterns Arduino Team — June 20th, 2019 If you’ve been waiting for a new way to generate geometric art, then be sure to check out the Cycloid-O-Matic from InventorArtist Darcy Whyte. This three-axis cycloid drawing machine is something of an update on the classic spirograph toy, but instead…

-

Modular CNC machine made with Arduino

Reading Time: 2 minutesModular CNC machine made with Arduino Arduino Team — May 15th, 2019 Arduino boards running GRBL software have long been used for CNC machine control, but usually you need to choose between having a router or laser cutter. This project, however, is specifically designed to accommodate both with a modular carriage system.…

-

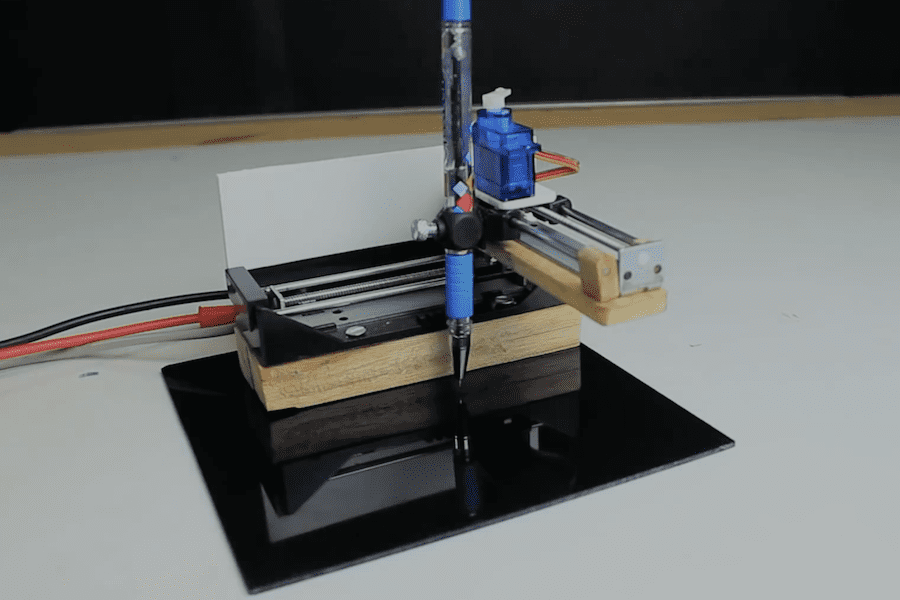

Make a mini CNC drawing machine

Reading Time: < 1 minuteMake a mini CNC drawing machine Arduino Team — January 21st, 2019 For an easy plotter design that you can build with only simple hand tools, be sure to check out this tiny project from Mr Innovative. The machine features a pair of stepper and lead screw assemblies to maneuver a…

-

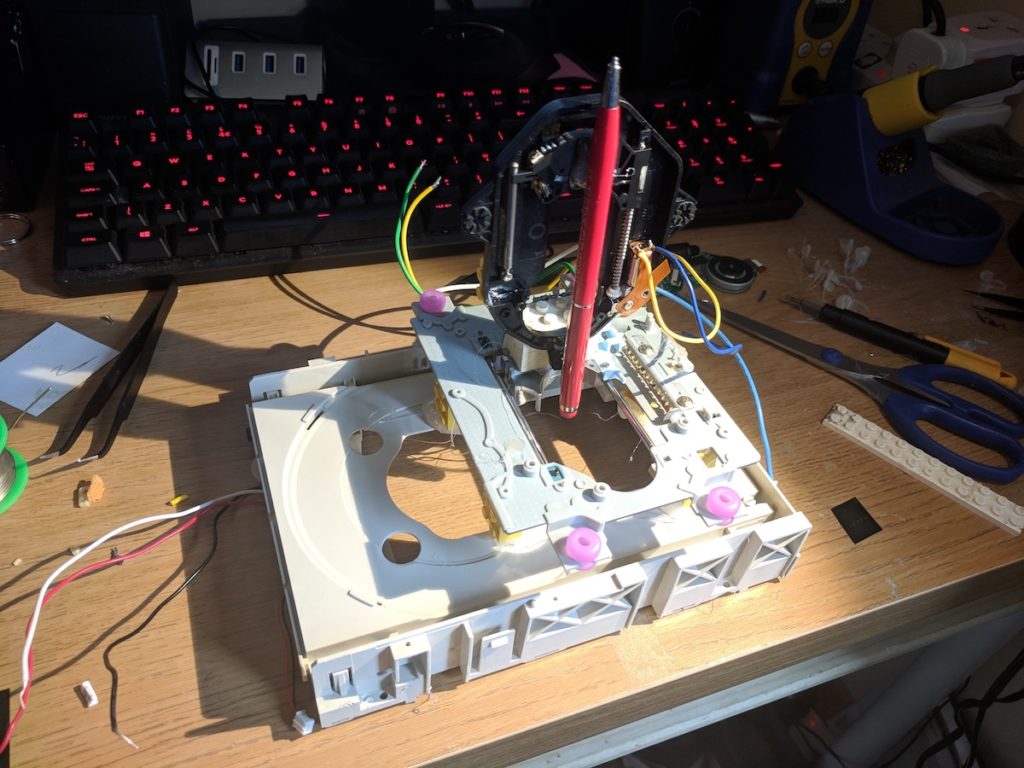

Two CD-ROM drives combined into fledging drawbot

Reading Time: < 1 minuteTwo CD-ROM drives combined into fledging drawbot Arduino Team — July 26th, 2018 Even if you don’t have access to fancy tools like a 3D printer or CNC router, that doesn’t mean you can’t make something interesting. James, using only a “hot glue gun, some scissors, and a screwdriver,” was able…