Schlagwort: Clocks

-

This spinning spiral clock is hypnotizing

Reading Time: 2 minutesSometimes makers come across products that they’d love to buy, but which are too expensive to justify. When that happens, the natural inclination of the maker is to build a DIY version. Such projects often end up costing way more — in both time and literal currency — than the product would…

-

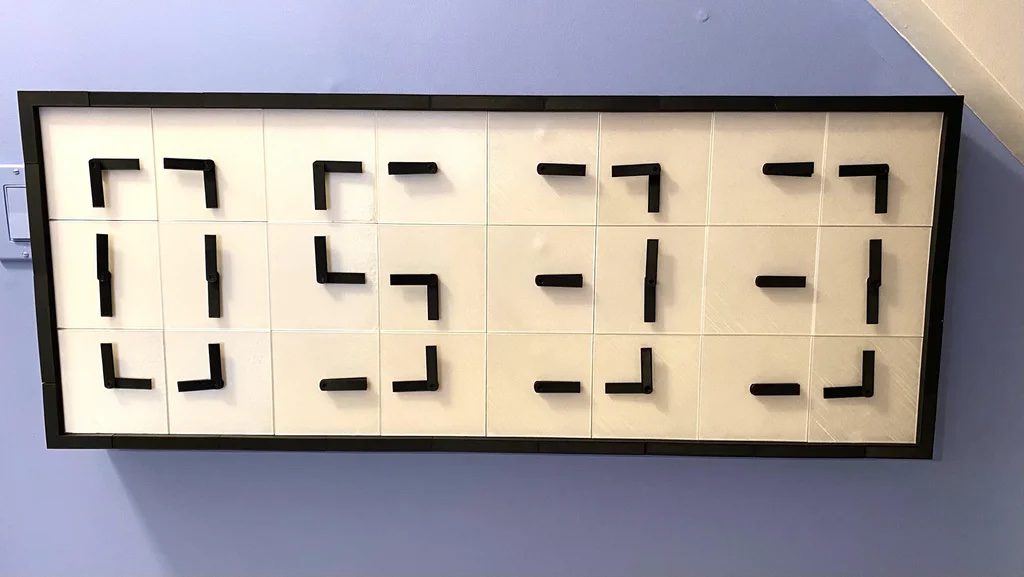

3D-printed digital clock contains 24 analog clocks

Reading Time: 2 minutesClocks are fantastic means of creative expression, as they serve a practical purpose and therefore have a reason to exist, but aren’t limited to pure functionality. As such, we see many interesting clock designs. But ihart’s 3D-printed digital clock made from 24 individual analog clocks takes the proverbial cake. When observed from…

-

This insane kinetic clock robot flips itself into position

Reading Time: 2 minutesArduino Team — February 23rd, 2022 Displaying the time these days is trivial — you could do it with any Arduino board and a simple four-digit seven-segment display. But as humans, we crave novelty and it isn’t uncommon to see a clock that is more art than a practical timekeeping device. That…

-

This 3D-printed, three-sided clock tells time with three hands

Reading Time: 2 minutesArduino Team — February 9th, 2022 Back in April 2021, Instructables user saulemmetquinn had the idea to build a fully 3D-printed clock that was based on the Triangulum constellation, which as the name implies, is a triangle. But it wouldn’t only tell the time using the typical set of hands and numbers, but also the current…

-

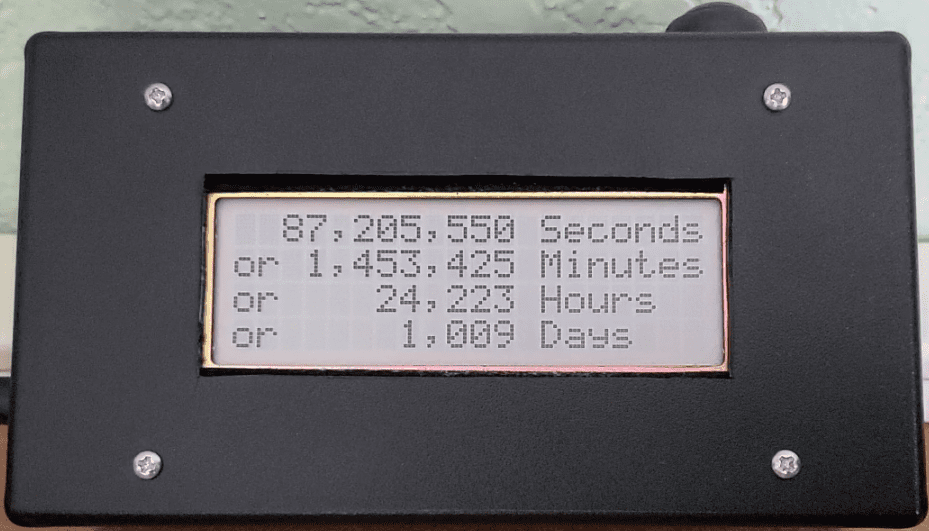

This clock counts down to retirement

Reading Time: 2 minutesArduino Team — January 14th, 2022 For most people, the idea of retiring is a very exciting thought. Finally, after decades of hard work, you can clock out for the last time and spend the rest of your life relaxing and enjoying your leisure years. RdRnr318’s coworker updates her whiteboard every day…

-

A DIY digital clock with a twist

Reading Time: 2 minutesArduino Team — December 27th, 2021 The digital clock has existed in its current form for decades at this point, so it’s quite exciting to see when a new take on the classic design comes along. The Time Twister 5, created by Hans Andersson, is a fully 3D-printed electromechanical clock that twists certain blocks…

-

Holo Clock is a novel 3D-printed clock that tells time using a pair of rings

Reading Time: 2 minutesArduino Team — August 10th, 2021 Simply looking at a traditional analog clock sitting on a wall somewhere got pretty boring for one Instructables user who goes by saulemmetquinn, which is partially why they wanted to create a novel design instead. Their device uses almost entirely 3D-printed components that come together to…

-

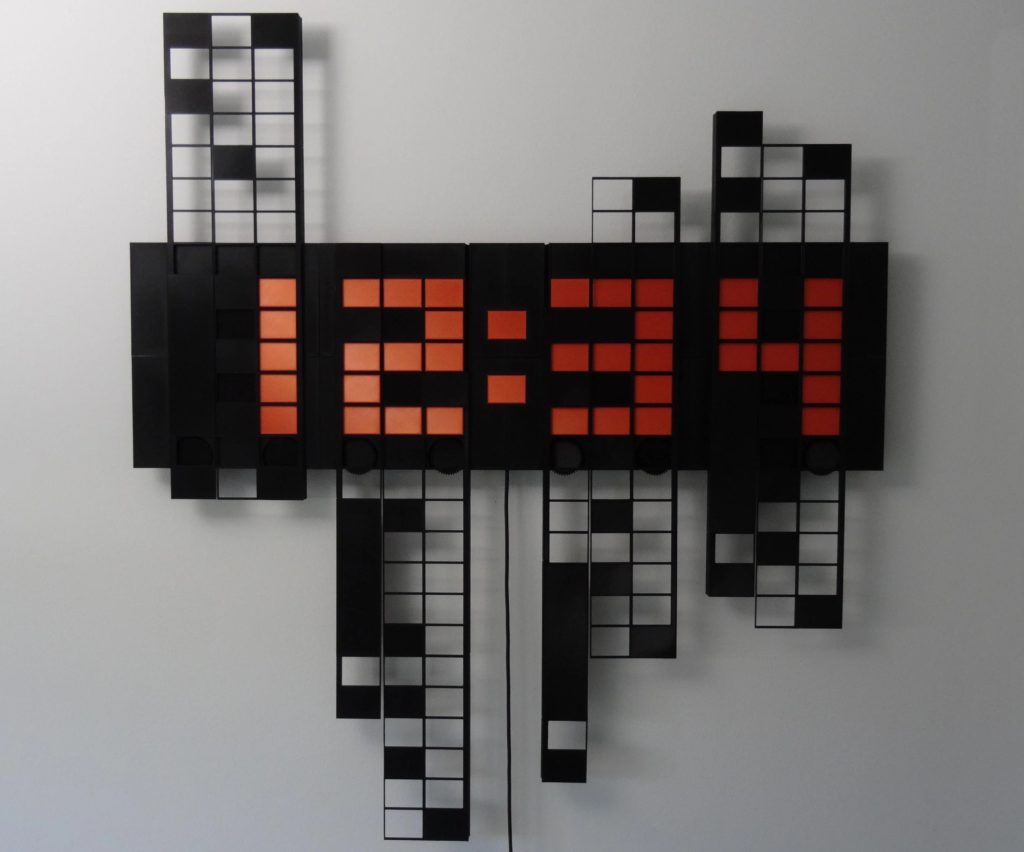

Kinetic digital clock takes 7-segment displays to another dimension

Reading Time: 2 minutesArduino Team — July 20th, 2021 Seven-segment displays have been around for ages, and they have a really cool retro aesthetic about them. Over on Instructables, user alstroemeria (known as Jacky Mok in real life) decided to build a different kind of display that utilizes individual servo motors to slide the segments out, thus creating a…

-

The MonKlock tells time using the Cistercian numeral system

Reading Time: 2 minutesArduino Team — June 25th, 2021 Way back in the 13th century, an order of monks known as the Cistercians created a unique numbering system that used a series figures and rotations to represent numbers up to 9,999 in just a single character. Because these numerals are so great in compact displays, using them in…

-

This digital clock uses 24 Arduino-controlled analog faces

Reading Time: < 1 minuteThis digital clock uses 24 Arduino-controlled analog faces Arduino Team — March 5th, 2021 After being inspired by a beautiful, if rather expensive timepiece, Ira Hart decided to make a 3D-printed clock with 24 analog faces that combine to form a single digital display. The overall device is controlled by a single…

-

Get the time from GETULA, a modular chain link clock

Reading Time: 2 minutesGet the time from GETULA, a modular chain link clock Arduino Team — January 5th, 2021 After observing a bicycle chain lying on the street in a random pattern, Ekaggrat Singh Kalsi was inspired to make a morphing clock that bends chains to tell time. The clock, known as “GETULA,” consists of four…

-

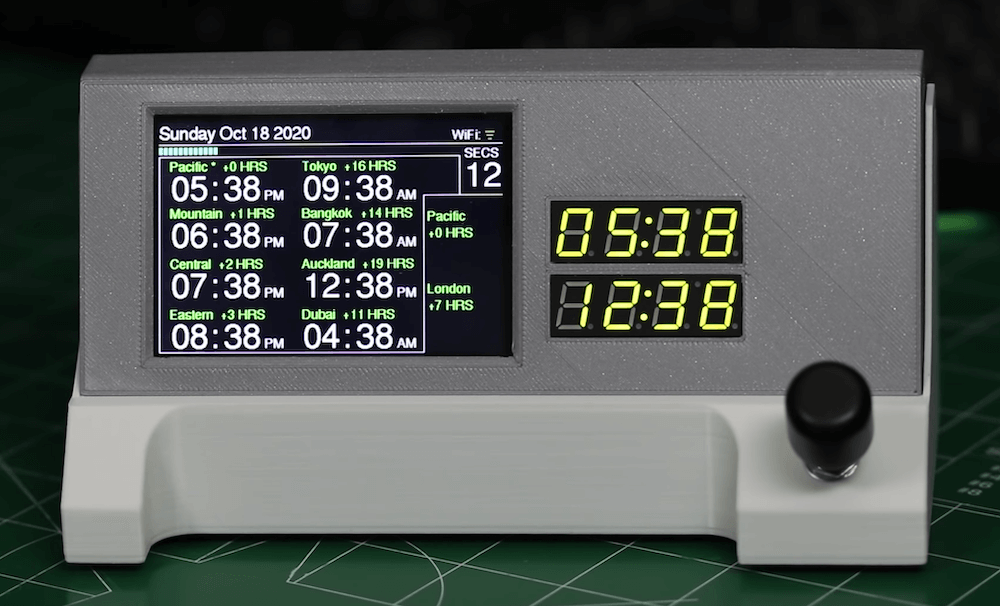

Know what time it is anywhere in the world with this Nano 33 IoT-based NTP clock

Reading Time: < 1 minuteKnow what time it is anywhere in the world with this Nano 33 IoT-based NTP clock Arduino Team — December 14th, 2020 Kaleb Clark, like many of us, works with others from all around the globe. While he could view any number of websites or commercial options to see what time…

-

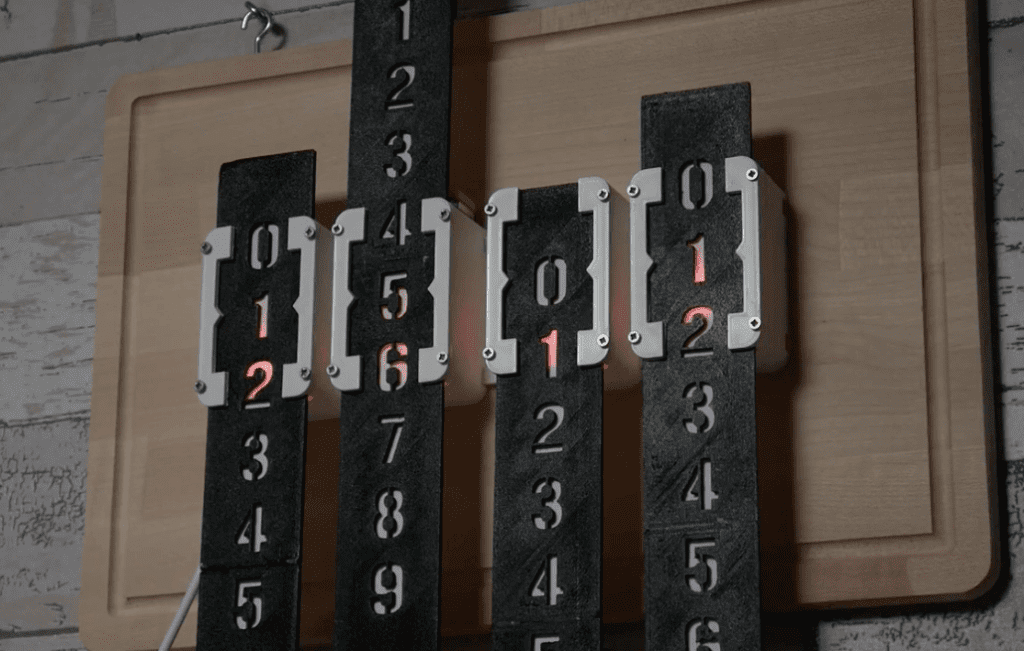

Tell time and temperature with sliding numbers

Reading Time: < 1 minuteTell time and temperature with sliding numbers Arduino Team — October 19th, 2020 While dial clocks are functional and well-understood, for something a bit more uniquely styled, Luuk Esselbrugge has created a 3D-printed timekeeping unit with four rows of sliding numbers. As seen here, each digit moves up and down to…

-

This Arduino-powered clock tells time in colors

Reading Time: 2 minutesThis Arduino-powered clock tells time in colors Arduino Team — October 7th, 2020 As humans, we’ve divided time up into 24 hours per day, 60 minutes per hour, and 60 seconds per minute. With many of us now working from home on differing schedules, time may seem a bit less concrete than…

-

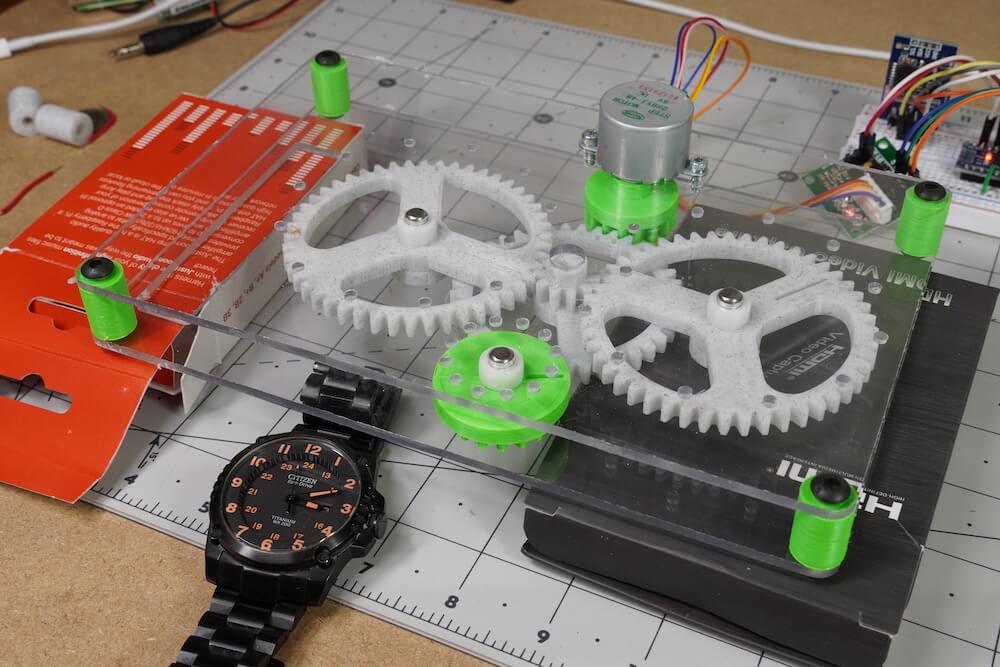

This stepper-driven mechanical clock can be set to two different time zones

Reading Time: < 1 minuteThis stepper-driven mechanical clock can be set to two different time zones Arduino Team — August 5th, 2020 Clocks normally tell you the time in your particular location, but what about that person that you know across the country or even on the other side the world? What time is it…

-

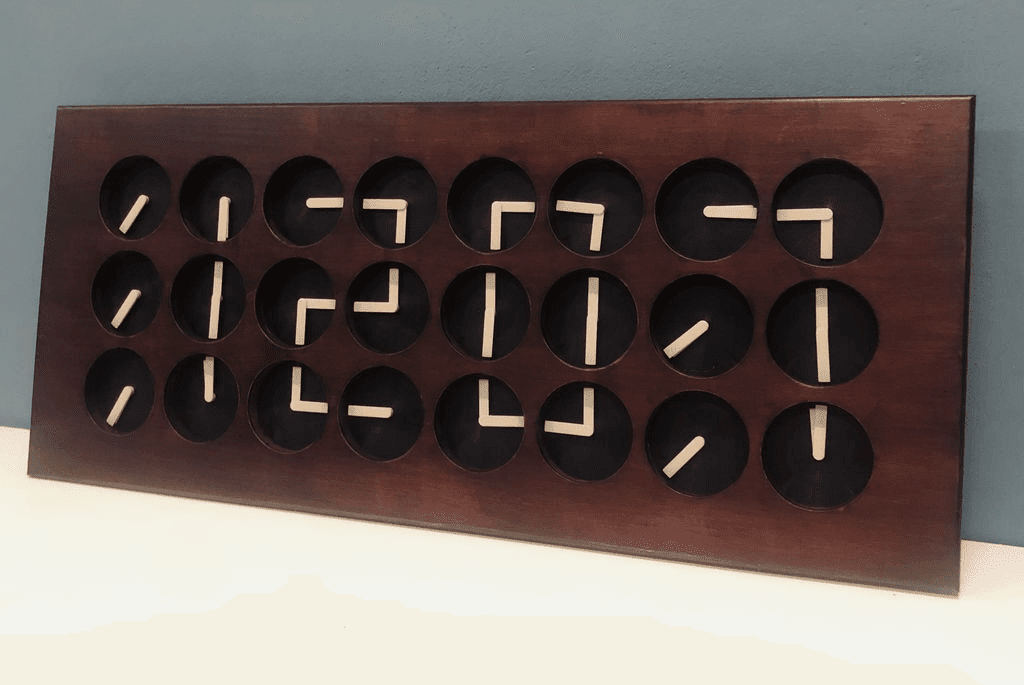

Create a digital clock out of 24 analog clocks

Reading Time: < 1 minuteCreate a digital clock out of 24 analog clocks Arduino Team — July 7th, 2020 What if you were to use the hands of a clock not as an individual display, but as part of an array that moves together to form digits? That’s the idea behind Clockception by “Made by Morgan,” which…

-

This tape measure shows the time of day in inches

Reading Time: < 1 minuteThis tape measure shows the time of day in inches Arduino Team — May 1st, 2020 Tape measures are great for determining length, width, and height. But what about the fourth dimension, time? Normally you’ll need a different device to show this ever-changing entity, but creators Alex Fiel and Anna Lynton…

-

Electromechanical 7-segment clock made with an Arduino and 28 servos

Reading Time: < 1 minuteElectromechanical 7-segment clock made with an Arduino and 28 servos Arduino Team — April 15th, 2020 Digital clocks are often made out of a series of 7-segment displays, which light up to represent the needed numbers. Michael Klements’ electromechanical project, however, doesn’t use LEDs, but instead physically flips 3D-printed segments into…

-

Check the time, date and conditions on this ILC1-1/8L clock

Reading Time: 2 minutesCheck the time, date and conditions on this ILC1-1/8L clock Arduino Team — October 24th, 2019 While OLED displays and the like are extremely versatile, there’s still something really charming about vintage VFD tubes. Christine Thompson (AKA ChristineNZ) in fact built her latest clock specifically to use eight ILC1-1/8L VFD tubes, which…

-

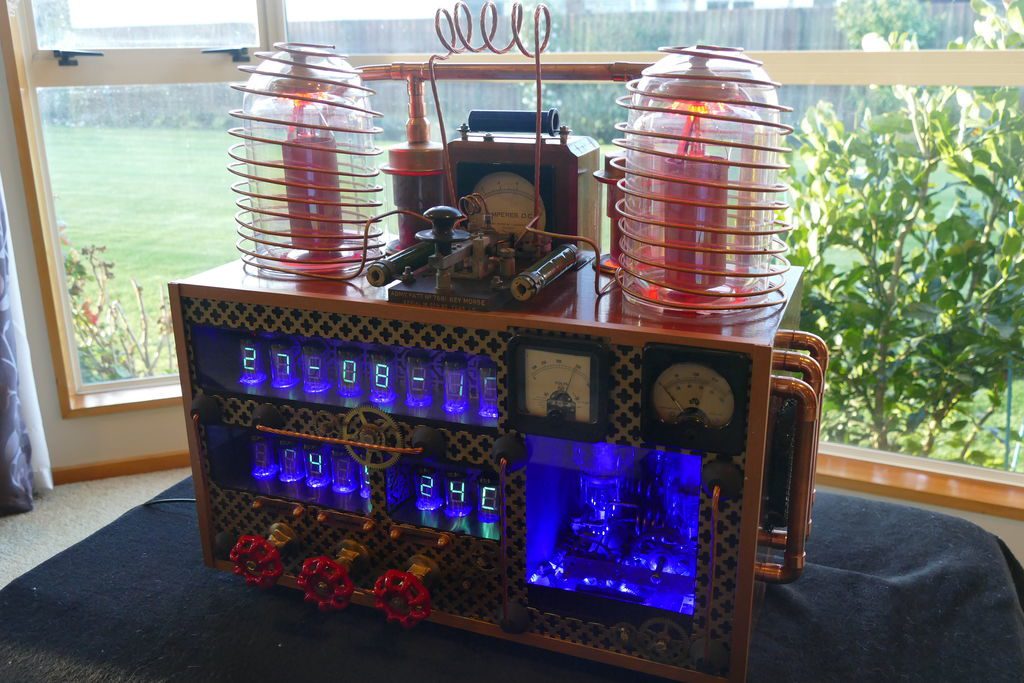

Steampunk radio and clock display with dual Arduino Mega control

Reading Time: 2 minutesIf you want to create your own steampunk/mad scientist entertainment center, it would be hard to top this radio/clock setup by Christine Thompson. Her device displays the time and date on eight VFD tubes, arranged on top of another eight that show the radio frequency and volume, along with the ambient temperature…

-

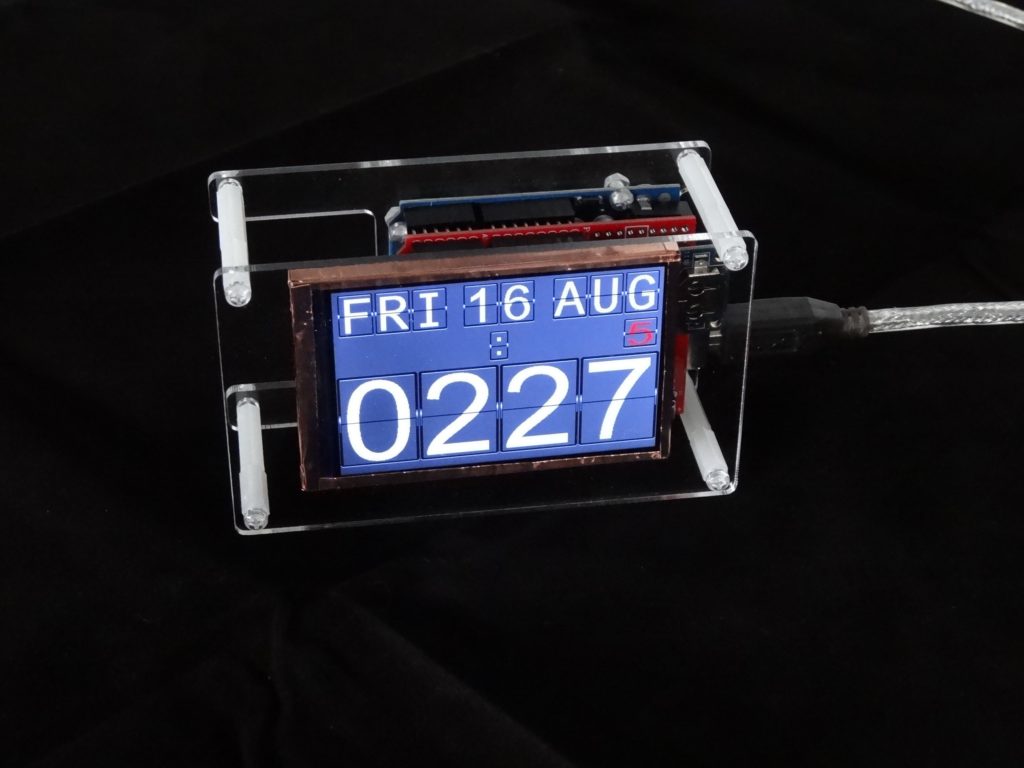

Simulating a flip clock on an Arduino-driven LCD screen

Reading Time: 2 minutesSimulating a flip clock on an Arduino-driven LCD screen Arduino Team — August 20th, 2019 Although flip clocks may be extremely interesting electromechanical devices, with rolling flaps to show what time it is, they’re also fairly complicated if you want to build one yourself. Mark Wilson, however, took a different approach with…