Schlagwort: Bioprinting

-

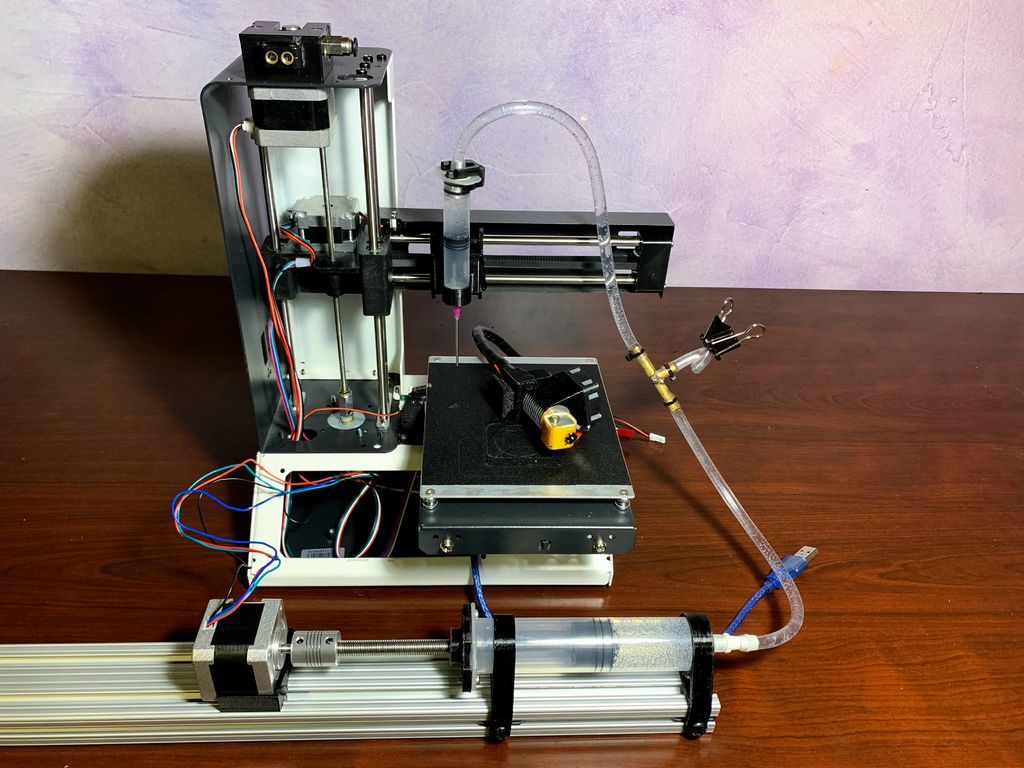

3D printer converted into a cheap bioprinting rig

Reading Time: 2 minutes3D printer converted into a cheap bioprinting rig Arduino Team — June 11th, 2019 While most 3D printers deposit melted plastic in carefully controlled positions to build up a physical model, a similar process called “bioprinting” can be accomplished with biological materials. Commercial bioprinters can cost tens of thousands of dollars or…

-

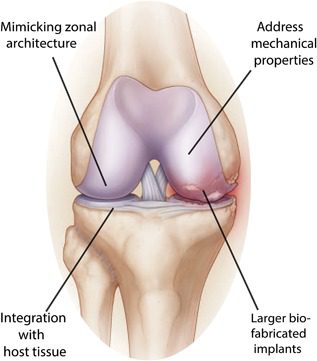

3D Printing Living Tissue Could Heal Damaged Joints and Eliminate Arthritis

Reading Time: 3 minutesA team of researchers from the University Medical Centre Utrecht in the Netherlands have created a biofabrication method to create living tissues that replicate cartilage and could potentially be implanted to repair damaged joints. Experienced by millions and millions across the world, arthritis is a physical disability that nearly one in ten…

-

Engineers Develop 3D Printing Method That Produces Tissue Scaffolding From Sugar

Reading Time: 4 minutesA team of engineers from the University of Illinois have developed a free-form isomalt 3D printing technology that produces intricate sugar-based scaffolding, which could potentially be used to grow tissue or study tumors. Slowly but surely, bioprinting is reshaping the medical landscape in multiple ways, from producing custom scaffolding to quite literally…

-

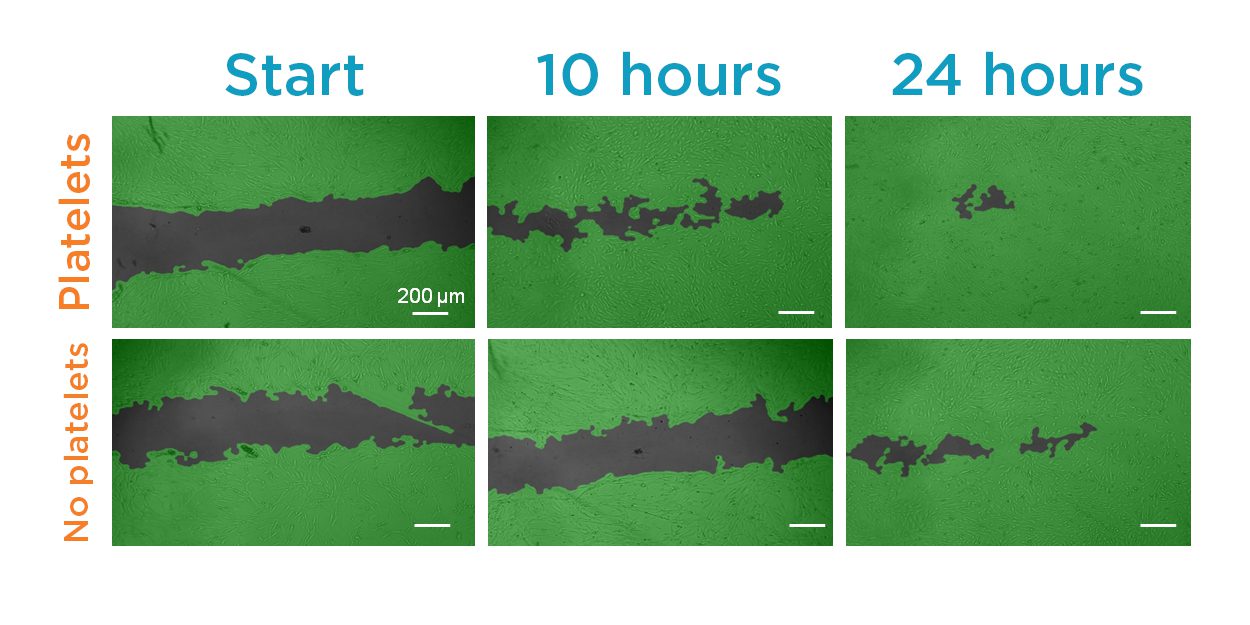

Printable Body Tissue with Personalized Bio-Inks Boost Healing Potential

Reading Time: 3 minutesBy embedding platelets into a 3D printed mixture of cells and gel, a team of researchers at the University of Nebraska-Lincoln hope to improve the healing properties of tissue implants and skin grafts with printable body tissue. Researchers from the University of Nebraska-Lincoln, MIT, and Massachusetts General Hospital have incorporated platelet-rich plasma…

-

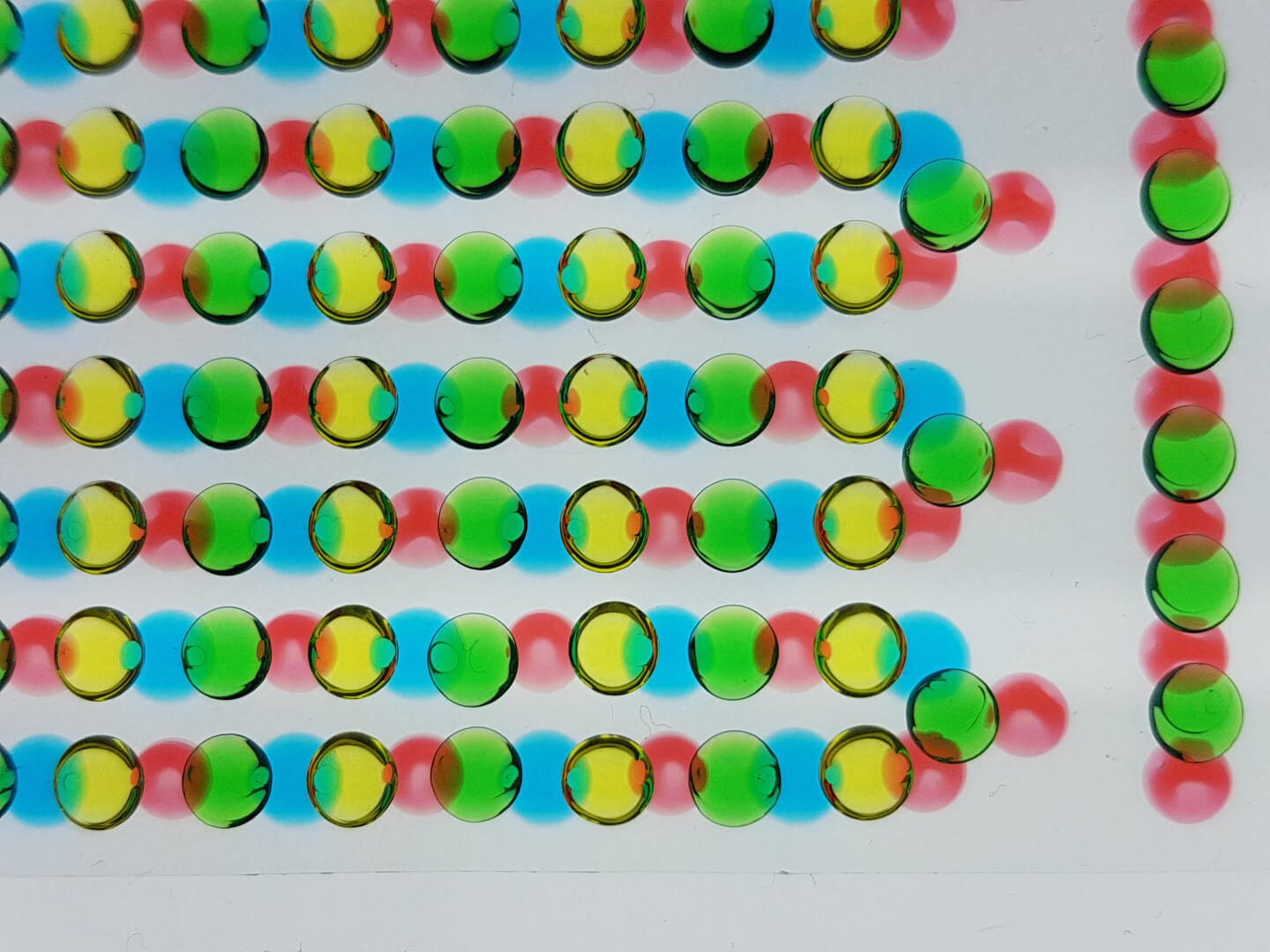

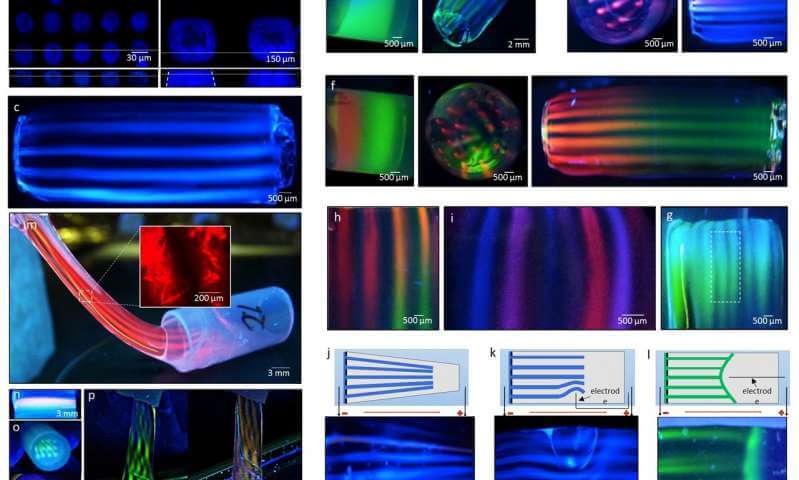

Electric Eels Inspire Device Which Reaches 110 Volts

Reading Time: 3 minutesA sheet of bioprinted hydrogels — inspired by the electric eel — is capable of delivering 110 volts of electricity. It has potential to become a soft power source which draws on a biological system’s chemical energy. Researchers used a 3D bioprinter to create a device which reached 110 volts from hydrogels.…

-

Molecular 3D Printing Technique Could Recreate Chemical Environments of the Human Body

Reading Time: 3 minutesScientists have developed an easy and affordable way to print biological environments without losing their chemical complexities. Biomedical engineering and the molecular sciences are among the many industries making use of 3D printing in order to find new ways to target drugs or develop human tissues and organs. Although a variety of…