To showcase their new flexible filament, 3D printer manufacturer BigRep fabricated a 3D printed airless bicycle tire and took it for a spin on the streets of Berlin.

Don’t Miss: BigRep Launches New Pro Flex Filament for 3D Printing

Summer’s here! It’s time to dust off your trusty bicycle and take it for a spin in the park. But wait, why is the rear tire looking so flat? Hmm, maybe you should take the roller blades instead…

Bicycle punctures are a royal pain, no doubt about it. And they’re also a fact of life for two wheeled transportation. But BigRep, a startup in Berlin that specializes in large format 3D printing, reckons they have a viable solution.

They’ve fabricated a 3D printed airless bicycle tire, and they’ve taken it for a ride on the city streets. The tire looks very similar to the prototypes devised by Michelin and others for the automotive industry. Only it’s been scaled down to fit the rims of a conventional city bike.

The tire is the work of designer Marco Mattia Cristofori, who you can also see taking it for a test ride in the video below:

What’s the Point of a 3D Printed Airless Bicycle Tire?

The beauty of a 3D printed airless bicycle tire is that it can be customized in terms of treads — whether for paths from pavement to mountain trails — and wheel size.

But can you expect to buy one in the not-too-distant future? According to BigRep, the prototype tire is primarily intended to showcase the potential of their new new Pro Flex filament. The material is based on TPU, and its flexible nature makes it perfect for an application like this.

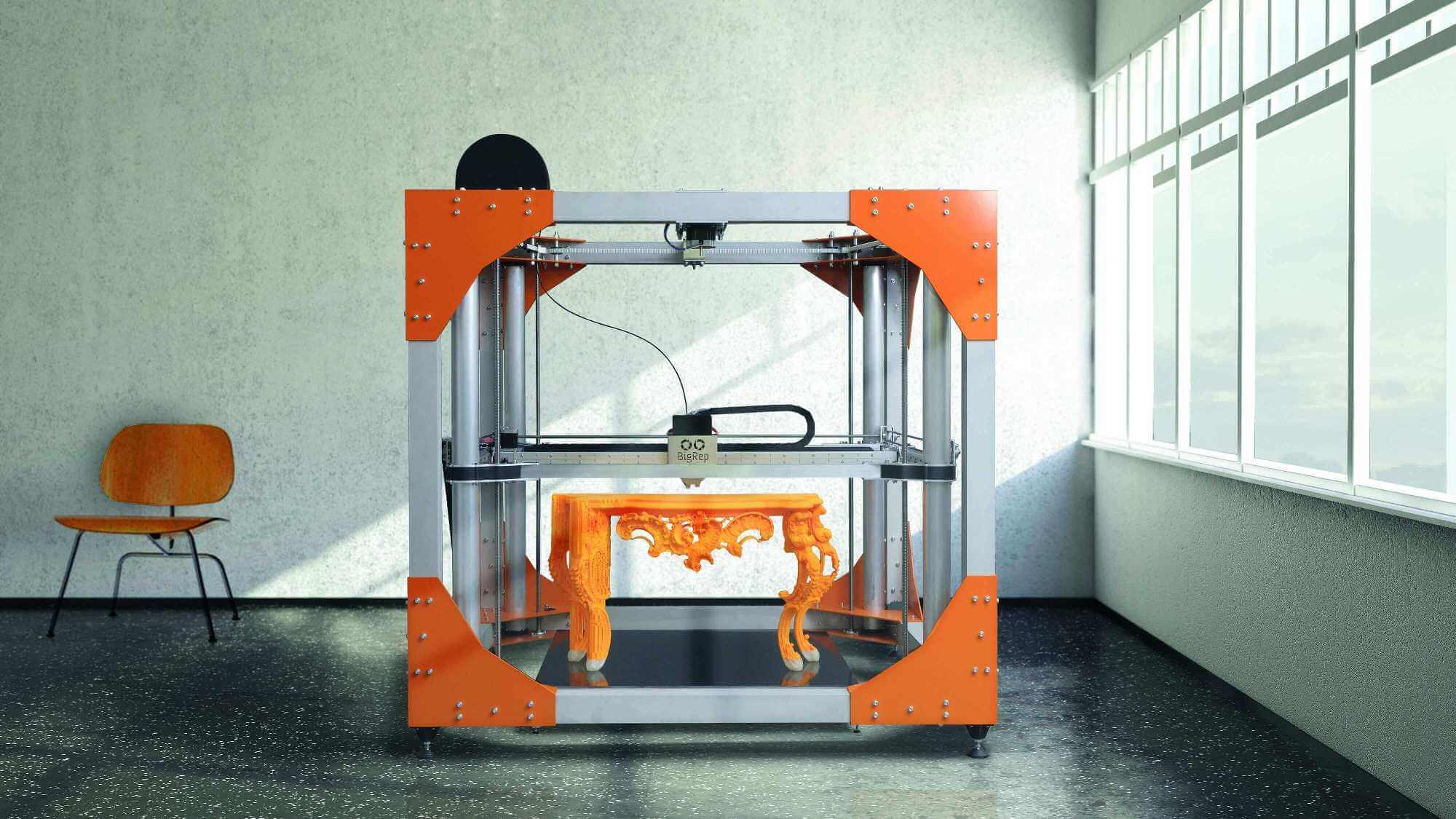

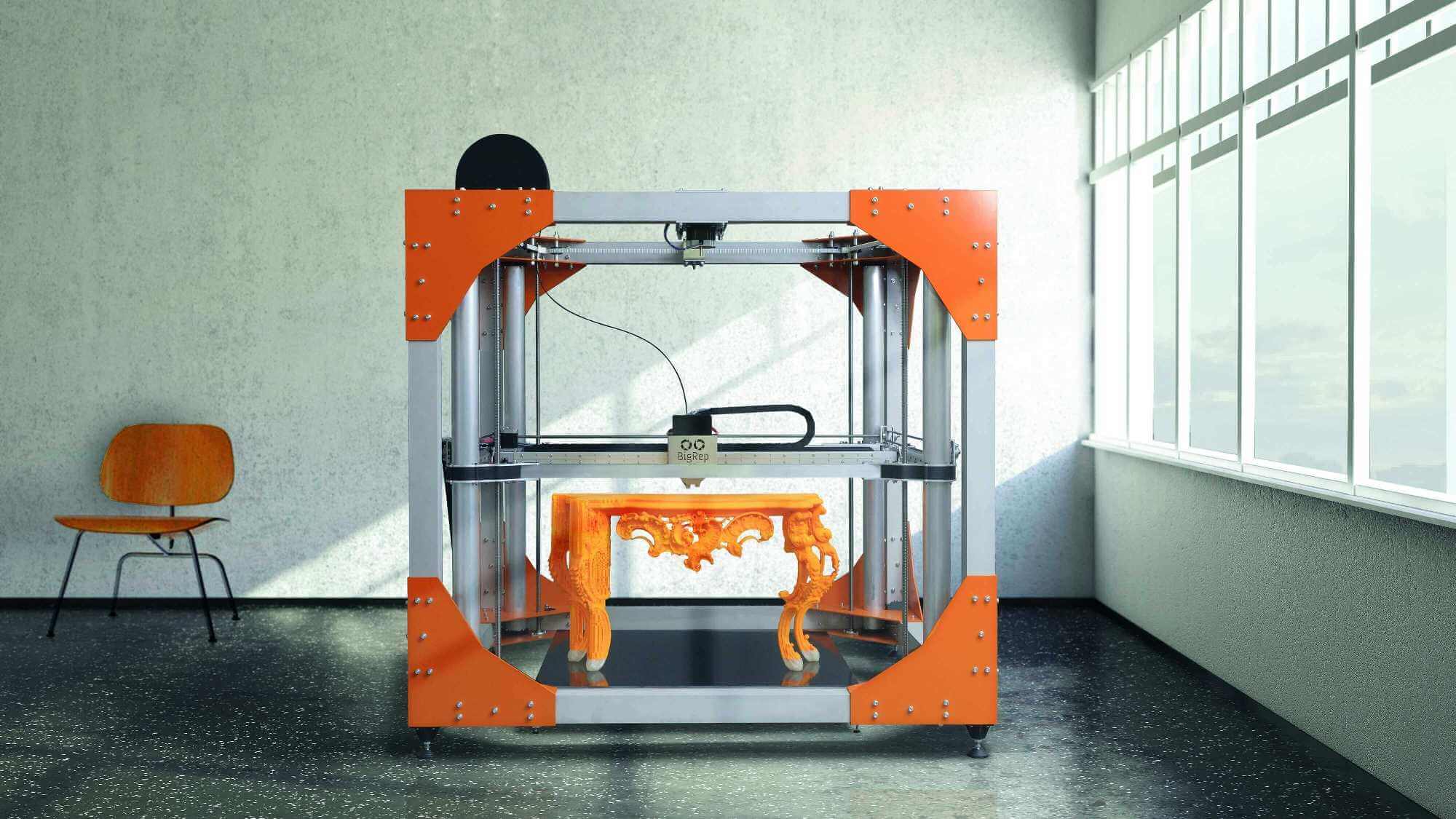

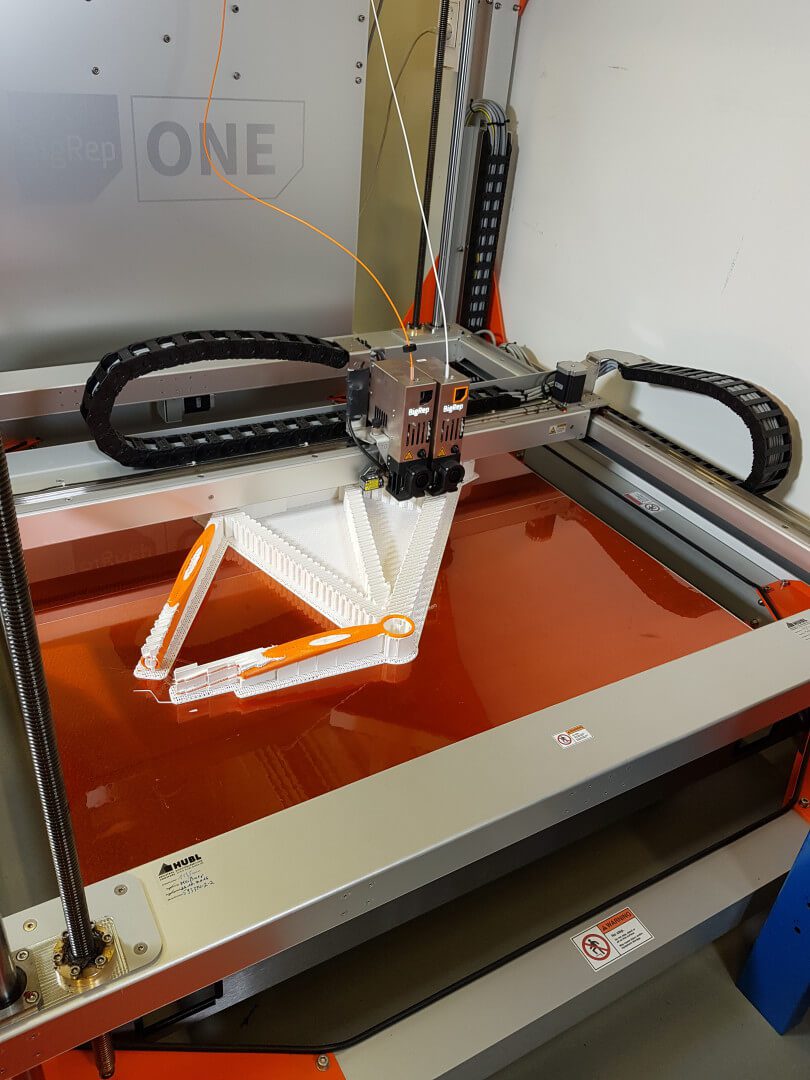

Used in conjunction with a BigRep One, an industrial 3D printer with a square meter build volume, Pro Flex can be used for rapid prototyping of items as diverse as skateboard wheels, sporting shoe shells, and ski tips.

Moreover, this is but one of a handful of BigRep projects concerning things of a circular nature. The company has also created a 3D printed custom wheel rim for a car, and a group of engineers used a BigRep machine to print out a functional bicycle frame.

So it’s unlikely that BigRep will be going into the bicycle tire business anytime soon. But they’ve certainly blazed a trail for others to follow in their wake.

Website: LINK