Conserving energy is something every animal does, and we humans are no exception.

Especially when energy costs are high — something many of us have been uncomfortably aware of in recent years — figuring out ways to live life without burning through excess fuel (and polluting the environment) is a serious priority.

Technology has promised many solutions here, with all kinds of energy-saving products on the market claiming to cut energy bills in half while saving the planet. But how many of these gadgets actually work? And could it be better to make your own?

In this article, we’ll look at some of the most common energy-saving devices and some examples of homemade alternatives from Arduino users.

Why is energy saving important?

There are several good reasons to focus on saving energy, both for your own benefit and to help others. These include:

- It saves money. Energy costs are still high around the world, and being careful about managing your energy usage can have a significant impact on your energy bill.

- It helps save the planet. The burning of fossil fuels contributes to climate change, and wasting less energy means your personal impact on this will be lower.

- It’s healthier. Carbon emissions and other fuels can pollute the environment and negatively impact our collective health. According to one report, cutting energy consumption by 15% for one year could save six lives and save up to 20 billion US dollars in health costs.

What are energy-saving devices?

Energy-saving devices are products designed to help you cut down on your energy usage, and they can approach this task from many different angles. Here are a few of the most common examples:

- LED light bulbs that use significantly less electricity than their traditional incandescent counterparts.

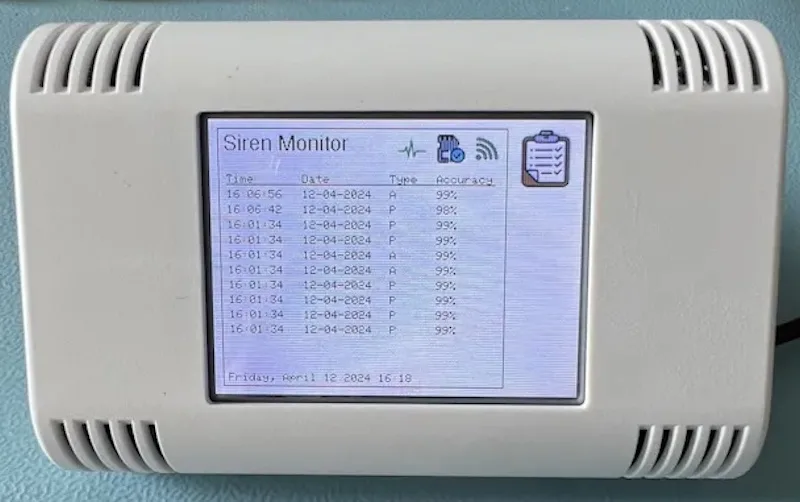

- Smart energy meters that keep track of your usage, suggest adjustments when energy is being wasted, and help you make more efficient and informed choices.

- Energy-efficient appliances like washing machines and AC units, designed to use minimal energy with no waste.

Do energy-saving devices really work?

So, do these devices really work, or is it just hype and marketing?

The (perhaps unsatisfying) answer is… sometimes. Some energy-saving devices like LED bulbs and highly rated efficient appliances can have a tremendous impact on your usage and save you noticeable amounts of money.

Others — especially more complicated-sounding devices that don’t come with official accreditation — may end up being a waste of money.

The third category here is devices that can work as long as you use them correctly. This applies to tools like smart meters, which can help you make extremely useful changes to your energy usage as long as you pay attention to them and act on the insights they provide.

3 ways to save energy with Arduino

You don’t have to buy your energy-saving devices from the store, of course. With some basic coding knowledge and a few simple components, you can put together your very own projects at home. Many Arduino users have done exactly that, with impressive results.

Let’s check some out!

Smart energy meters

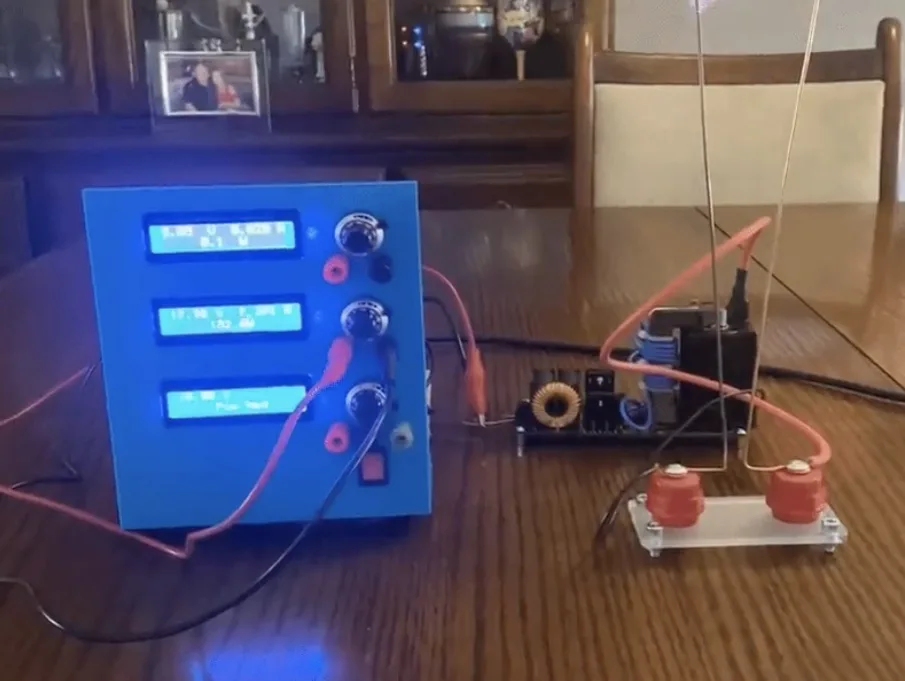

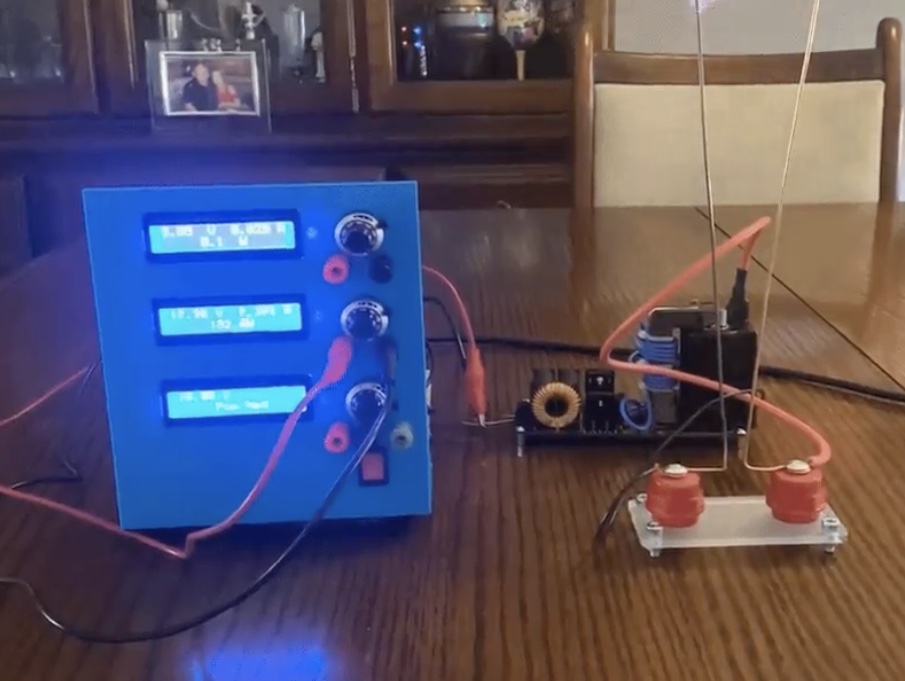

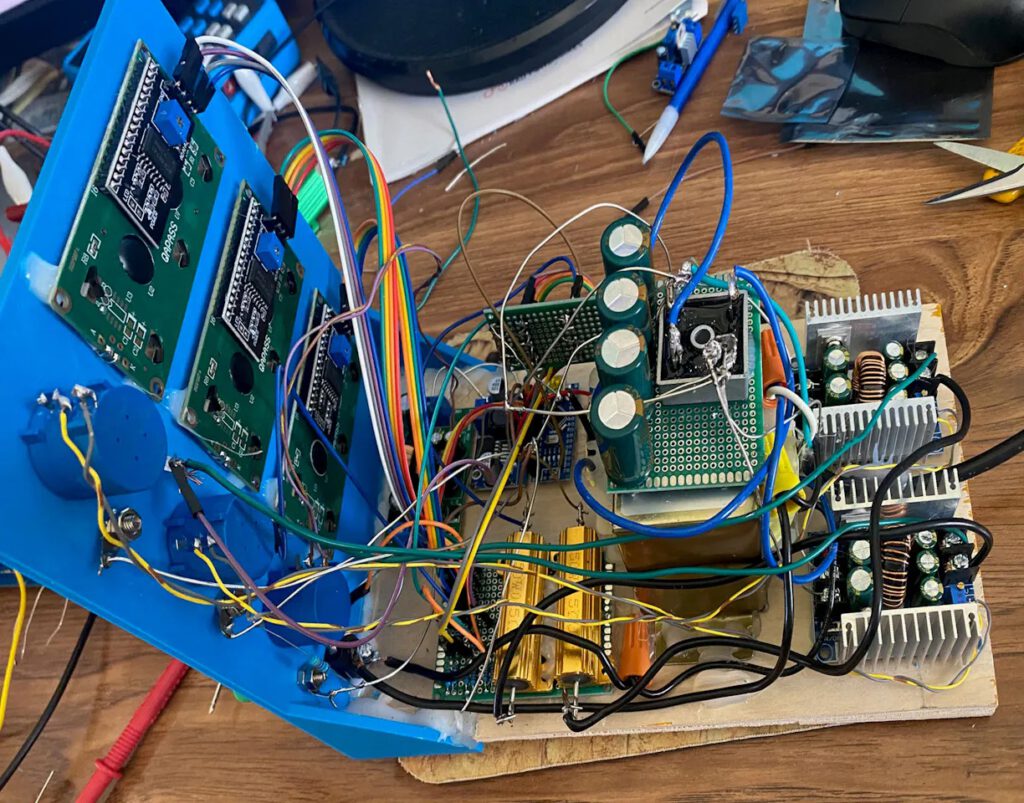

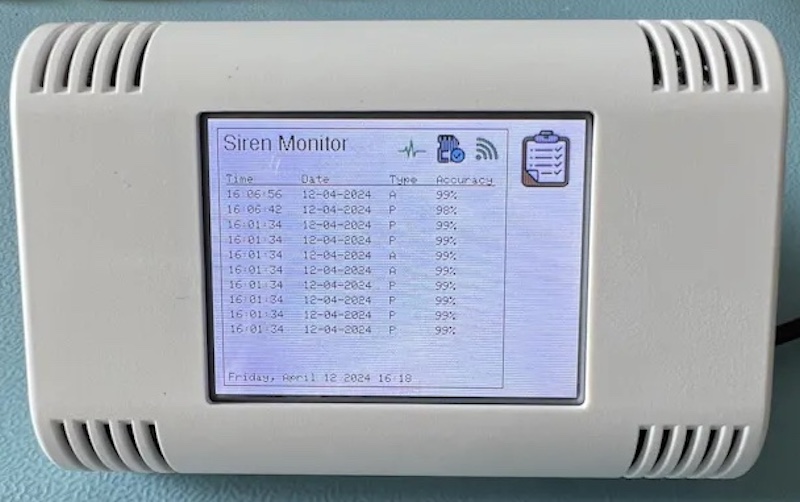

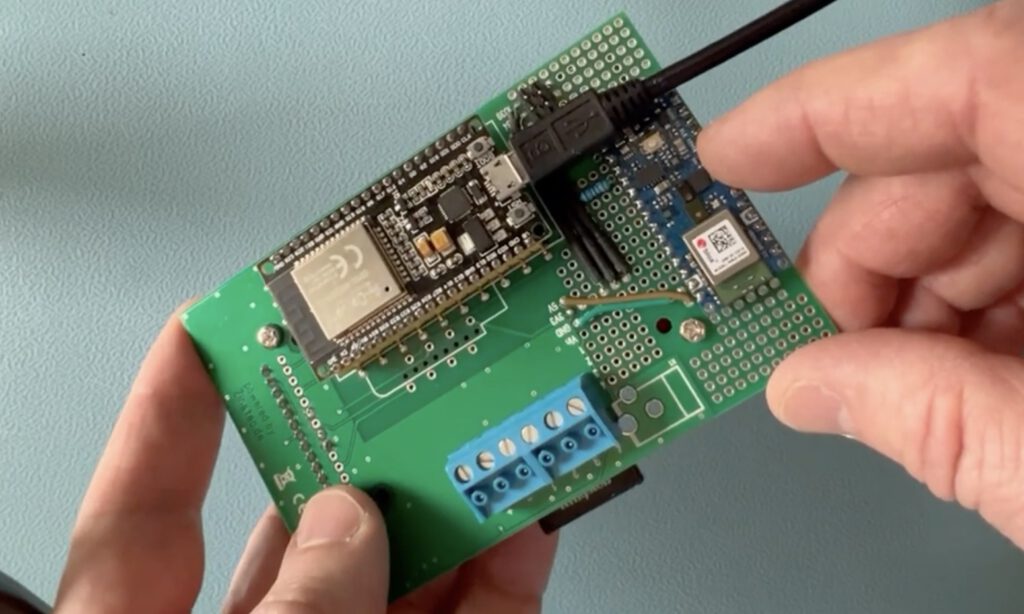

One Redditor and Arduino user decided to develop their own version of a smart meter to help monitor energy usage and save costs.

The device monitors amp, watt, and unit energy and allows you to view this data from your Android phone. Even more impressively, you can also turn devices on or off from your phone, managing your home’s energy usage from wherever you are. On top of that, if your devices consume more than 500W, the tool will turn them off automatically.

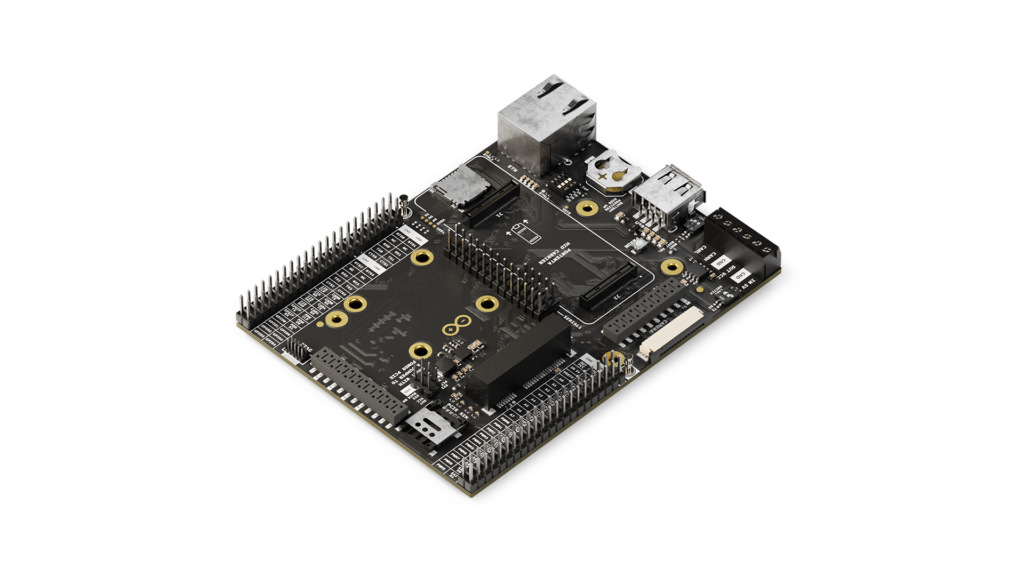

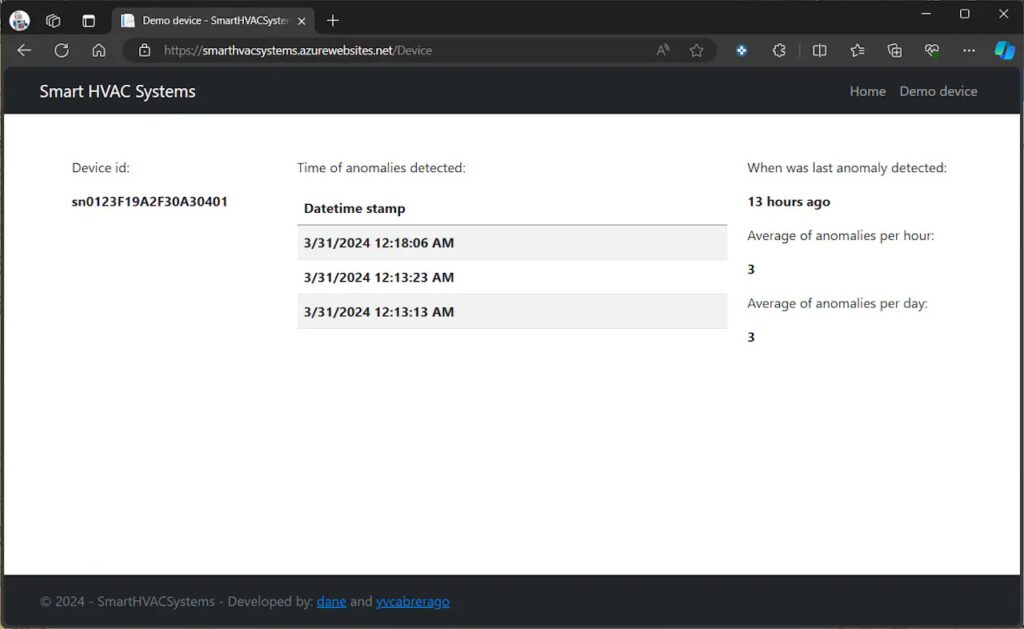

This Arduino IoT-based energy meter is another great example of how to carefully track your energy usage through the Arduino Cloud.

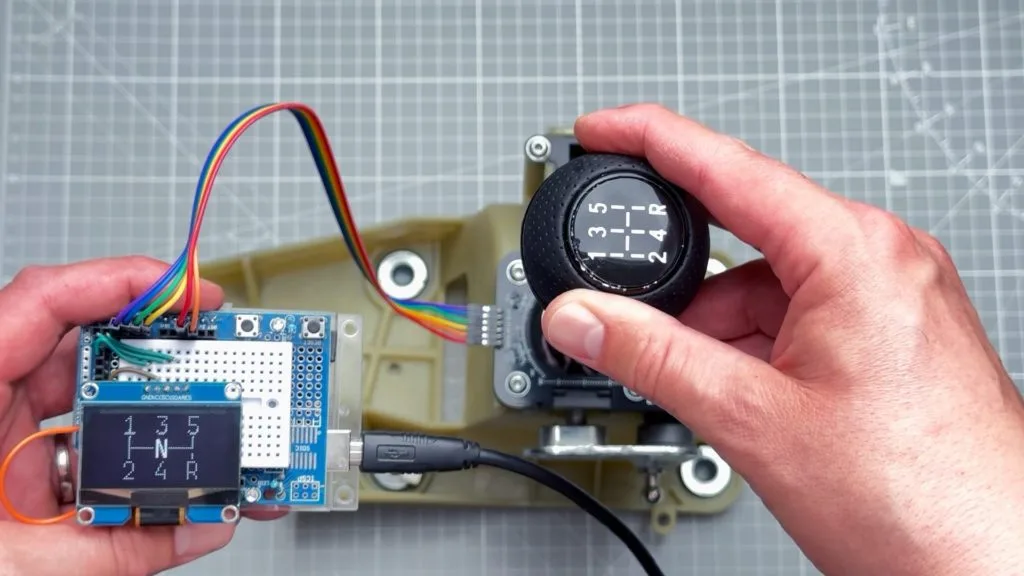

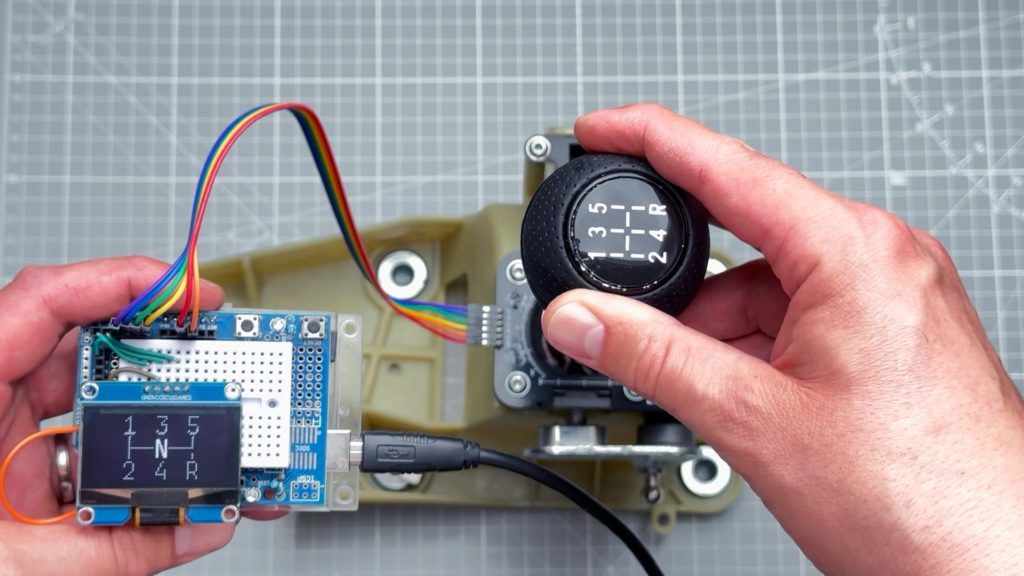

Glasses that save power

If your eyes are closed, do you even need the lights to be on?

That’s the idea behind a pair of glasses that automatically turn off the lights in your home whenever you close your eyes, helping you save on your electricity bill.

To add some extra spice, you can even add a TENS unit to make the glasses physically shock you into keeping your eyes closed longer. Evil, perhaps. Hilarious — definitely. Check out the video here.

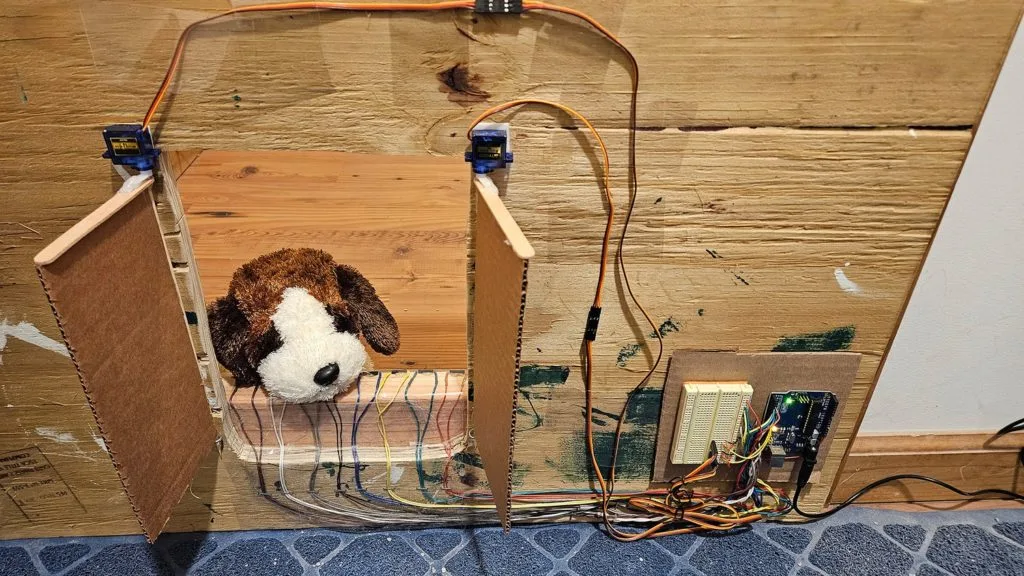

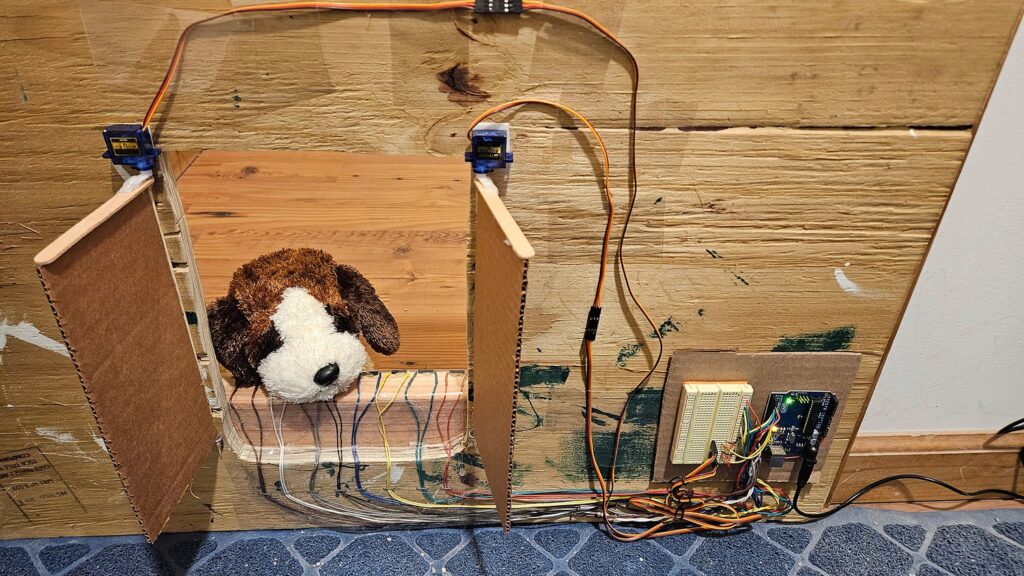

Snap circuits – energy saving

The best way to build lifelong good habits around energy saving is to start young.

EDUcentrum’s snap circuits project is designed to introduce kids to the world of circuitry and electronic prototyping, while also teaching them about energy saving.

The project teaches kids how to assemble their own snap circuits while learning about key topics like home automation and energy saving.

Share your own Earth Day projects!

Have you made any energy-saving devices or projects of your own? If so, we’d love to hear about them. Share the details in the comments below!

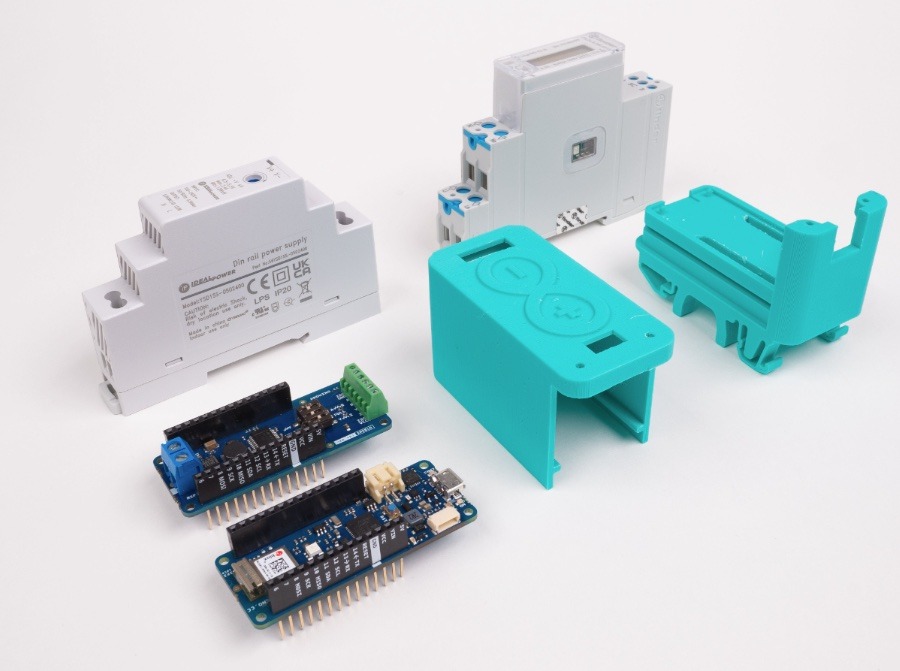

Psst! For a limited time, we’re offering a special opportunity to create your own sustainable smart project with the Arduino Cloud, an all-in-one IoT solution to visualize your sensor data with stunning dashboards. Follow these three steps to give it a try:

1. Visit Arduino Cloud plans and choose the Monthly Maker plan.

2. Enter code EARTHDAY during checkout, valid between April 19th and April 30th, 2024.

3. Unlock access to all advanced features, including over-the-air updates, unlimited shareable dashboards, data retention, real-time alerts and much more.

Whether you’re passionate about conservation or simply curious about the possibilities, now is your chance to join the community and make a difference. This offer is exclusively for new users not currently on any paid plan. You will have the flexibility to cancel at any time.

Don’t miss out — embrace innovation while honoring our planet.

The post How to make energy saving really work appeared first on Arduino Blog.

Website: LINK