Schlagwort: 3D printing materials

-

FDM vs SLA – 2018 3D Printing Technology Shootout

Reading Time: 7 minutesCheck out our FDM vs SLA Shootout. We simply explain the differences between these 3D printing technologies, and which to use for which application. FDM vs SLA: Explained The Prusa i3 MK3 is one of the finest consumer 3D printers you can get. It uses FDM technology to get things printed. (Source: ALL3DP)…

-

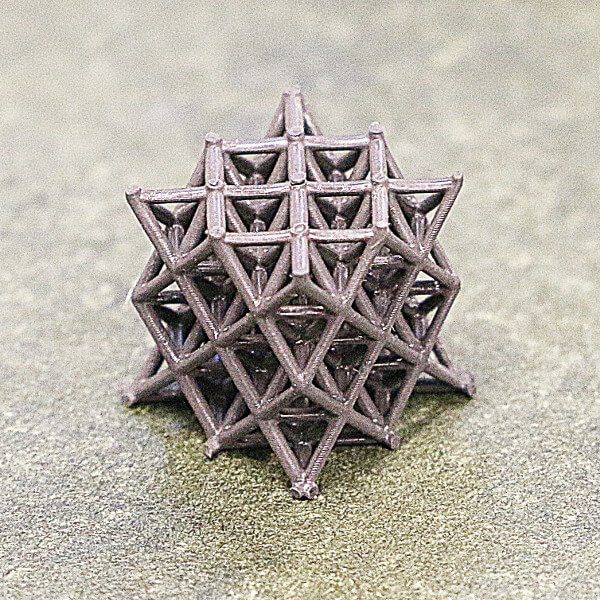

Researchers Develop 3D Printed Metamaterials That Can Control Vibration and Sound

Reading Time: 4 minutesResearchers from USC Viterbi School of Engineering have developed 3D printed metamaterials that can switch between active control and passive states, enabling control of acoustic and optical waves. A team of researchers at the USC Viterbi School of Engineering has just developed acoustic metamaterials that can be controlled via magnetic fields. While…

-

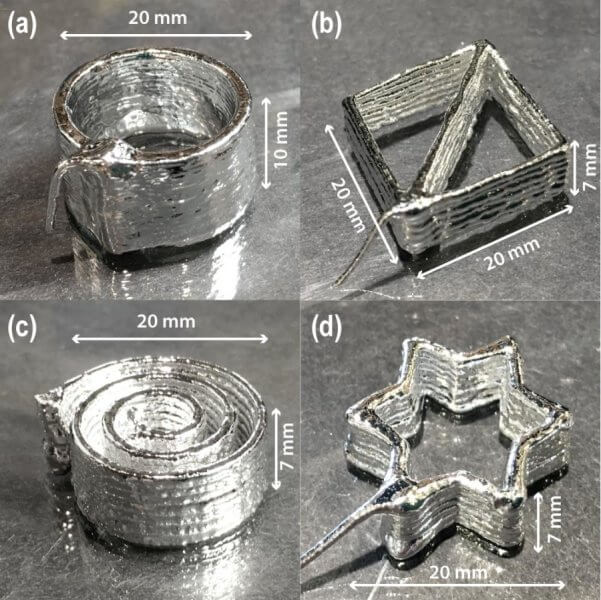

3D Printable Gallium Alloys Could Lead the Way for Flexible Electronics

Reading Time: 3 minutesOregon State University’s College of Engineering researchers have made progress in the ability to rapidly manufacture flexible electronics and soft robotics. Flexible computer screens would undoubtedly be a cool improvement to laptops, hopefully making them more difficult to crack. Amazingly, this isn’t an impossible dream. Researchers from Oregon State University’s College of Engineering…

-

i.Materialise Adds New Untreated Brass to Finishing Options

Reading Time: 2 minutesi.materialise is adding untreated brass to its range of finishing options – print your designs in basic brass without polish, coating or plating to give them a vintage look. If you’re 3D printing jewelry or miniatures and want to create a vintage appearance, you’ll be interested to hear about i.materialise’s most recent…

-

Polymaker Launches PolyMide CoPA Nylon Material Made with Warp-Free Technology

Reading Time: 3 minutesPolymaker is launching a new Nylon material called PolyMide CoPA. This engineering-grade filament is created with Warp-Free technology, which provides the mechanical advantages of Nylon without risk of warpage. Polymaker, the 3D printing filament producer based in Shanghai, has been slowly moving itself towards the forefront of material innovation. Over the last year, the…

-

Kwambio Reveals Brand-New Ceramic 3D Printer at CES

Reading Time: 3 minutesThere aren’t many machines capable of 3D printing ceramics (find an in-depth overview here). Not only are there just a handful of machines commercially available, also the process hasn‘t changed much in years. Kwambio, an NYC-based startup, wants to offer a new angle. They built their high-precision 3D printer, Ceramo One, specifically for 3D…