Schlagwort: 3D Printing Industry

-

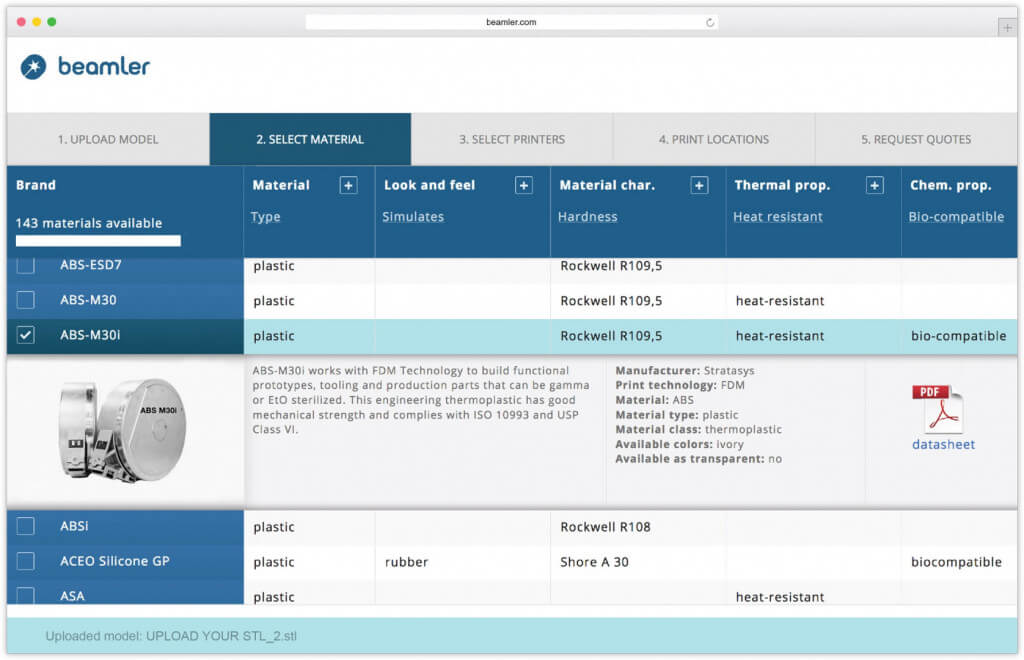

3D Printing Software company Beamler Acquires Printr

Reading Time: 3 minutesBeamler, the company that provides 3D printing software for the industry, has just announced the acquisition of Printr. It will be fully integrated into the buyer’s portfolio. Printr was founded in 2014 by students in the Netherlands. The company sought to make 3D printing more accessible. One of the major bottlenecks in…

-

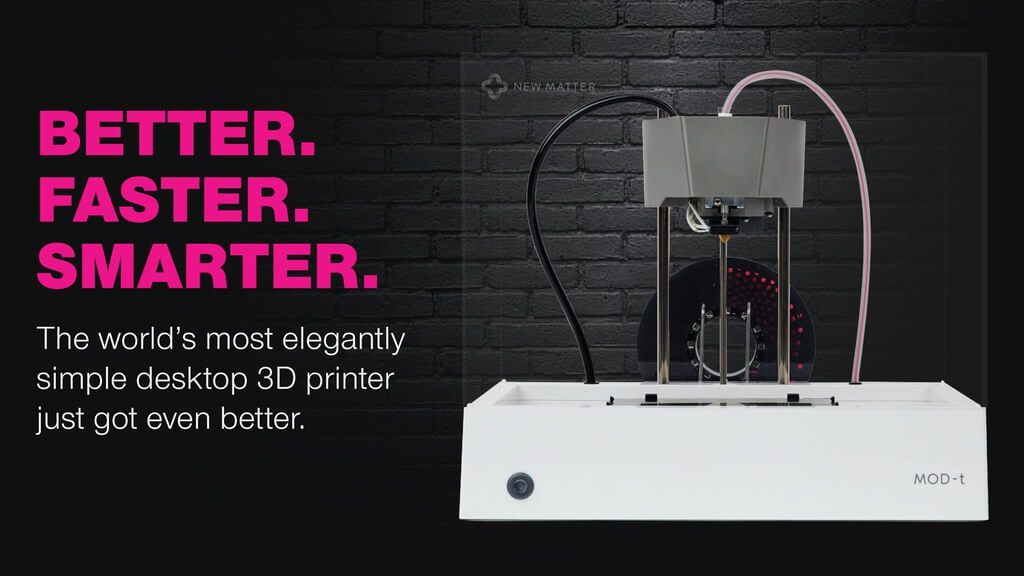

New Matter is Another 3D Printing Company Closing Down

Reading Time: 4 minutesFor the second time this month, a 3D printer company is shuttering their doors. New Matter will cease operations at the end of Febuary; providing limited support to owners of the MOD-t 3D printer. Don’t Miss: Type A Machines Retire to that Great 3D Printer in the Sky Last week we reported…

-

3-in-1 Snapmaker 3D Printer: Review the Facts Here!

Reading Time: < 1 minuteThe concept of the Snapmaker 3D printer is a modular machine with three distinct functions. The intended audience is the workshopper pushed for space. First and foremost, the Snapmaker is an all-metal 3D printer. The aluminum frame encases all wiring, with the exception of a few tidy ribbon cables. But the…

-

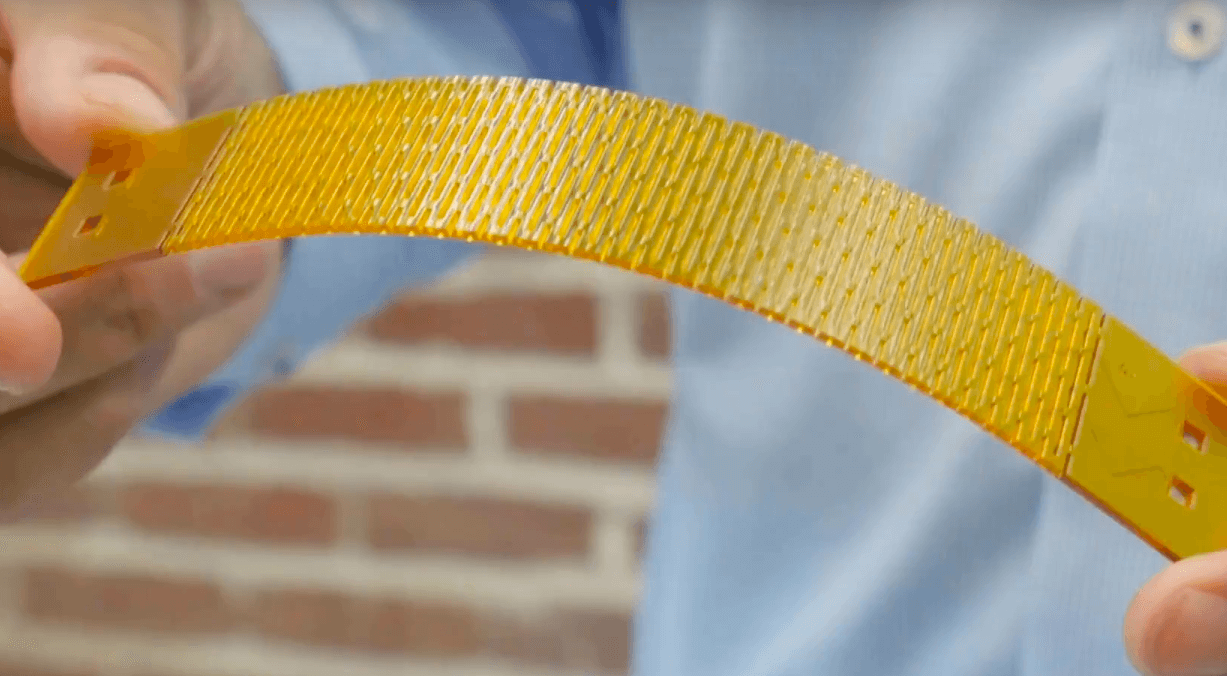

Solidworks Add-In for DragonFly2020 Pro Makes Creating 3D Printed Electronics Easier

Reading Time: 2 minutesNano Dimension, known for their circuit boards 3D printers, partnered up with software company Dassault Systèmes and implemented a Solidworks add-in for its DragonFly 2020 Pro 3D printer. The DragonFly 2020 Pro is a 3D printer from Nano Dimension which was unveiled last September. It is designed to manufacture embedded electronics and circuit…

-

New HP Jet Fusion 300 / 500 Series With Full Color 3D Printing

Reading Time: 3 minutesHP introduces new industrial 3D printers capable of full-color engineering-grade parts. Prices for the new HP Jet Fusion 300 / 500 series start from $50,000, making innovation accessible to small to medium-sized businesses and academic institutions. Don’t Miss: With Multi Jet Fusion, HP Challenges Injection Molding Today sees the launch of the…

-

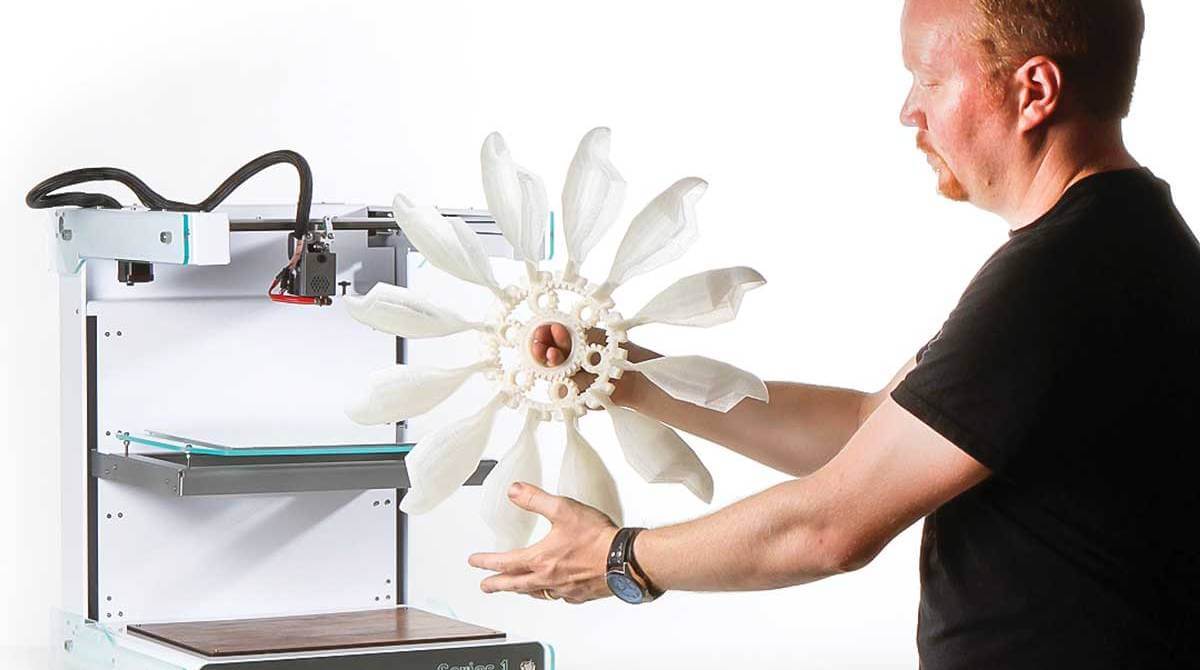

Raise3D N2 3D Printer: Review the Facts Here!

Reading Time: 2 minutesThe Raise3D N2 Plus has a huge build volume of 12″ x 12″ x 12″. Additionally, the entire printer is fully enclosed with a sturdy aluminum metal frame and ABS, acrylic, and poly-carbonate casing. The fully enclosed design not only improves print quality when printing with materials such as ABS, but also…

-

Type A Machines Retire to that Great 3D Printer in the Sky

Reading Time: 3 minutesDespite their multiple innovations in the desktop 3D printer market, California-based manufacturer Type A Machines has gone out of business. The past year has seen a dramatic change to the desktop 3D printer industry; the market is flooded with cheap DIY 3D printer kits, and established hardware manufacturers are struggling to compete.…

-

3D Printing & Additive Manufacturing Conferences 2018

Reading Time: < 1 minuteLocation: São Paulo, Brazil What is it?: Participants will see 3D printing business applications and demonstrations of the latest developments in printers and services, including programs for designers, artists, and manufacturers. Strength: At the Inside 3D Printing show you will see how 3D printing is revolutionizing the manufacturing, jewelry, medicine, architecture, the aerospace industry and many…

-

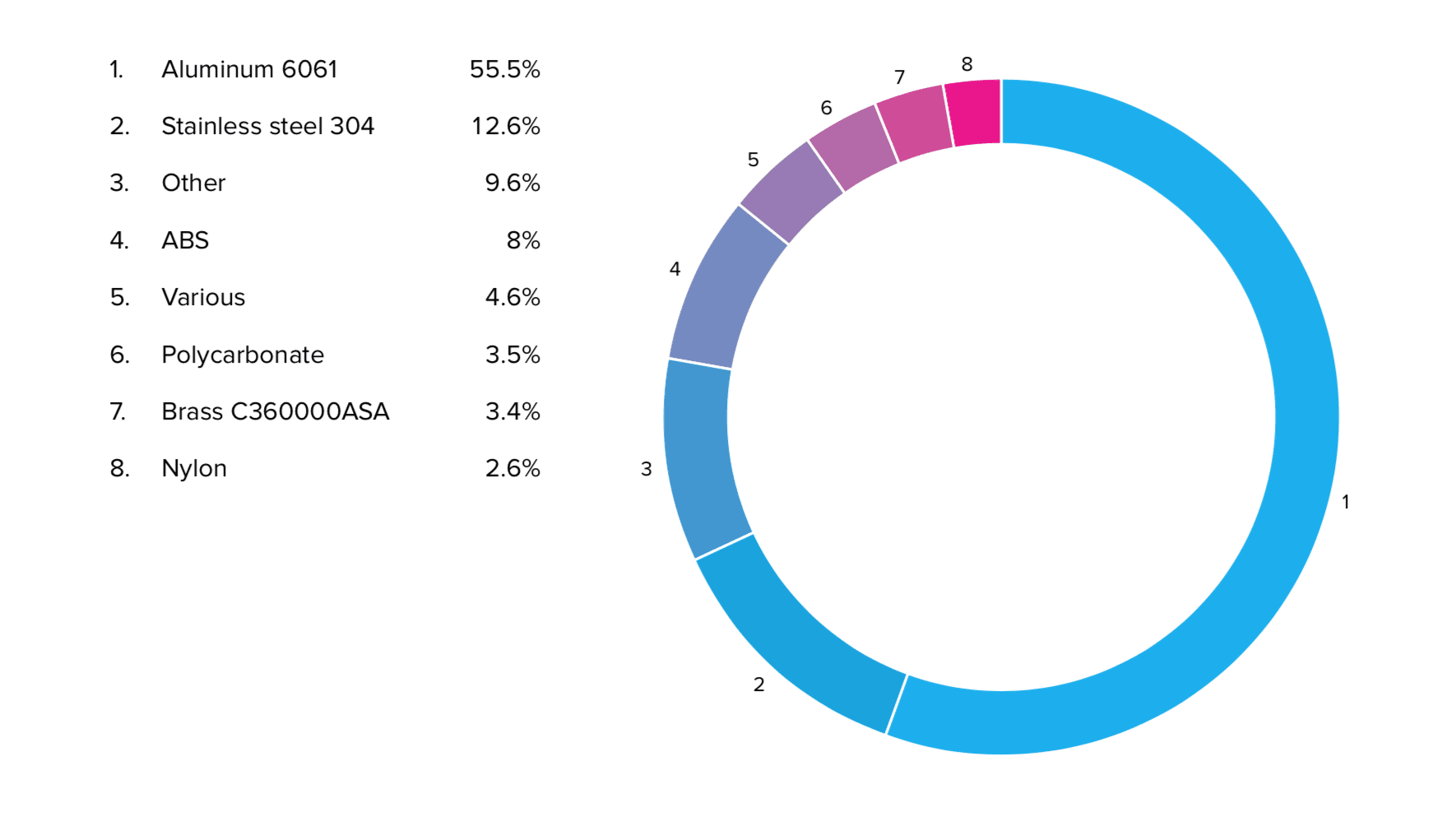

Two Big Strategic Changes from 3D Hubs

Reading Time: 3 minutesThe open peer-to-peer marketplace pioneered by 3D Hubs has been relegated, say the company founders, to make room for a broader manufacturing platform driven by CAD-CAM technologies. Don’t Miss: 3D Hubs CEO Responds to Criticism Over Recent Platform Changes Once upon a time, 3D Hubs could be simply described as an online…

-

Grohe Introduces 3D Printing to Streamline Design, Development, Production

Reading Time: 2 minutesGrohe, the world leader in supplying sanitary and water fittings, is planning to expand its production of fittings and incorporate 3D printing technology into its prototyping processes. Looks like Grohe Water Technology AG has big plans for 2018 including expanding its production of fittings by using 3D printing in a new pilot project.…

-

Formlabs Fuse 1 3D Printer: Review the Facts Here!

Reading Time: < 1 minuteIn June 2017, 3D printer manufacturer Formlabs announced the launch of Fuse 1, the company’s first selective laser sintering (SLS) 3D printer. “When we launched the world’s first desktop stereolithography 3D printer in 2012, Formlabs created new possibilities for designers and engineers to create physical products by giving them access to…

-

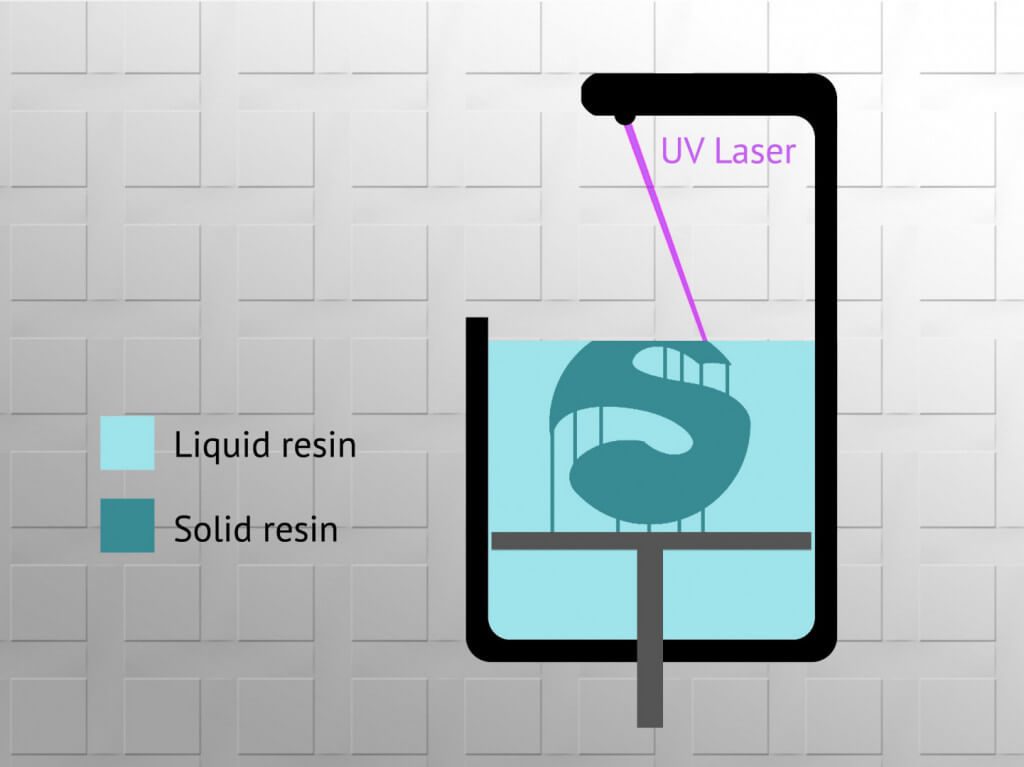

20 Best Resin (SLA/DLP) 3D Printers 2017 / 2018

Reading Time: 3 minutesWhen it comes to 3D printer sales, stereolithography (SLA) definitely trails behind fused deposition modeling (FDM). But in terms of quality, you’ll find that an SLA 3D printer is usually the way to go. If you choose an SLA 3D printer, you usually don‘t go for big builds, but for quality and highly…

-

Olli, 3D Printed Bus from Local Motors, Receives $1 Billion in Financing

Reading Time: 2 minutesLocal Motors secured over $1 billion in financing from Elite Transportation Services (ETS) and Xcelerate for its autonomous Olli bus customers. Whatever you think about driverless cars, taking a trip in an autonomous 3D printed bus would be an experience to remember. Don’t worry too much either, this bus, called the Olli, has a max…

-

3D Printing Industry Shares Their Predictions for 2018

Reading Time: 2 minutes2017 had a lot of interesting developments, going from metal 3D printing, to industry specialization, and the move towards mass manufacturing. A lot of new players entered the metal 3D printing market, but my feeling is that we’re still missing a practical innovation and compelling price point to be truly competitive. Regarding…

-

6 Safe Ways How To Remove 3D Prints From The Bed

Reading Time: < 1 minuteThis method works more subtle than the previous ones. Especially heated beds form a seemingly indestructible bond with the printed material sometimes. So the first step after a print has finished is to let the printer and the heated bed cool down completely. If you’re lucky, the print pops right off…

-

Kwambio Reveals Brand-New Ceramic 3D Printer at CES

Reading Time: 3 minutesThere aren’t many machines capable of 3D printing ceramics (find an in-depth overview here). Not only are there just a handful of machines commercially available, also the process hasn‘t changed much in years. Kwambio, an NYC-based startup, wants to offer a new angle. They built their high-precision 3D printer, Ceramo One, specifically for 3D…

-

Building the Original Prusa i3 MK3: Review the Facts Here!

Reading Time: 2 minutesSo what’s the big deal about the Original Prusa i3 MK3? It’s pitched as a refinement of everything Prusa Research have achieved to date; more than a reliability upgrade, but a new and improved desktop 3D printer with some awesome new features. Where the previous model offered astonishing print quality for the…

-

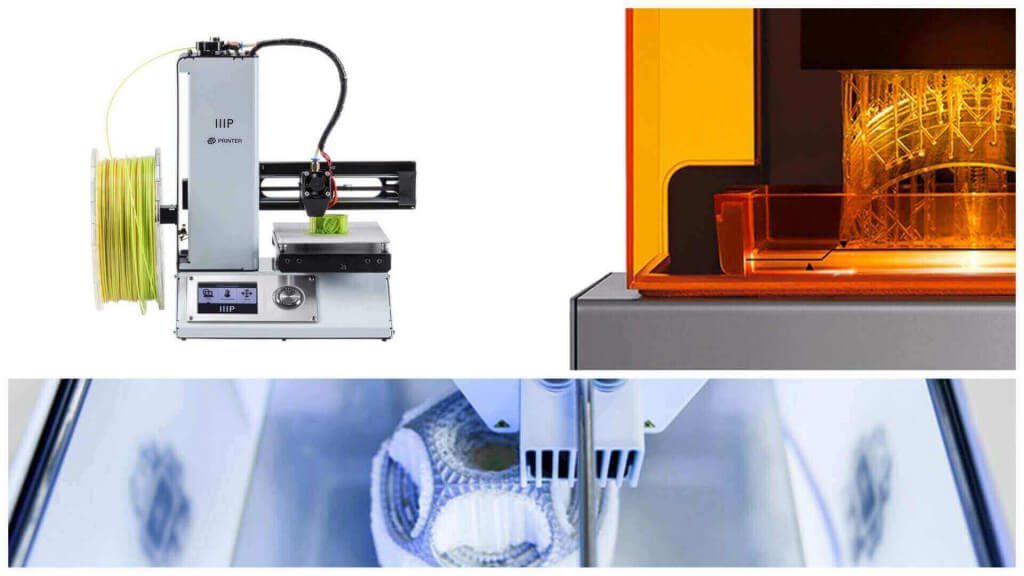

Best 3D Printer Awards 2017 / 2018 – The 12 Best 3D Printers

Reading Time: 4 minutesSelecting the best 3D printer for your needs is not an easy task. We want to make the process it a little bit easier with All3DP’s Best 3D Printer Awards. Finding the Best 3D Printer for Beginners If you are a newcomer to 3D printing, things can get overwhelming. Specifications and terminology…