Schlagwort: 3D printing in medicine

-

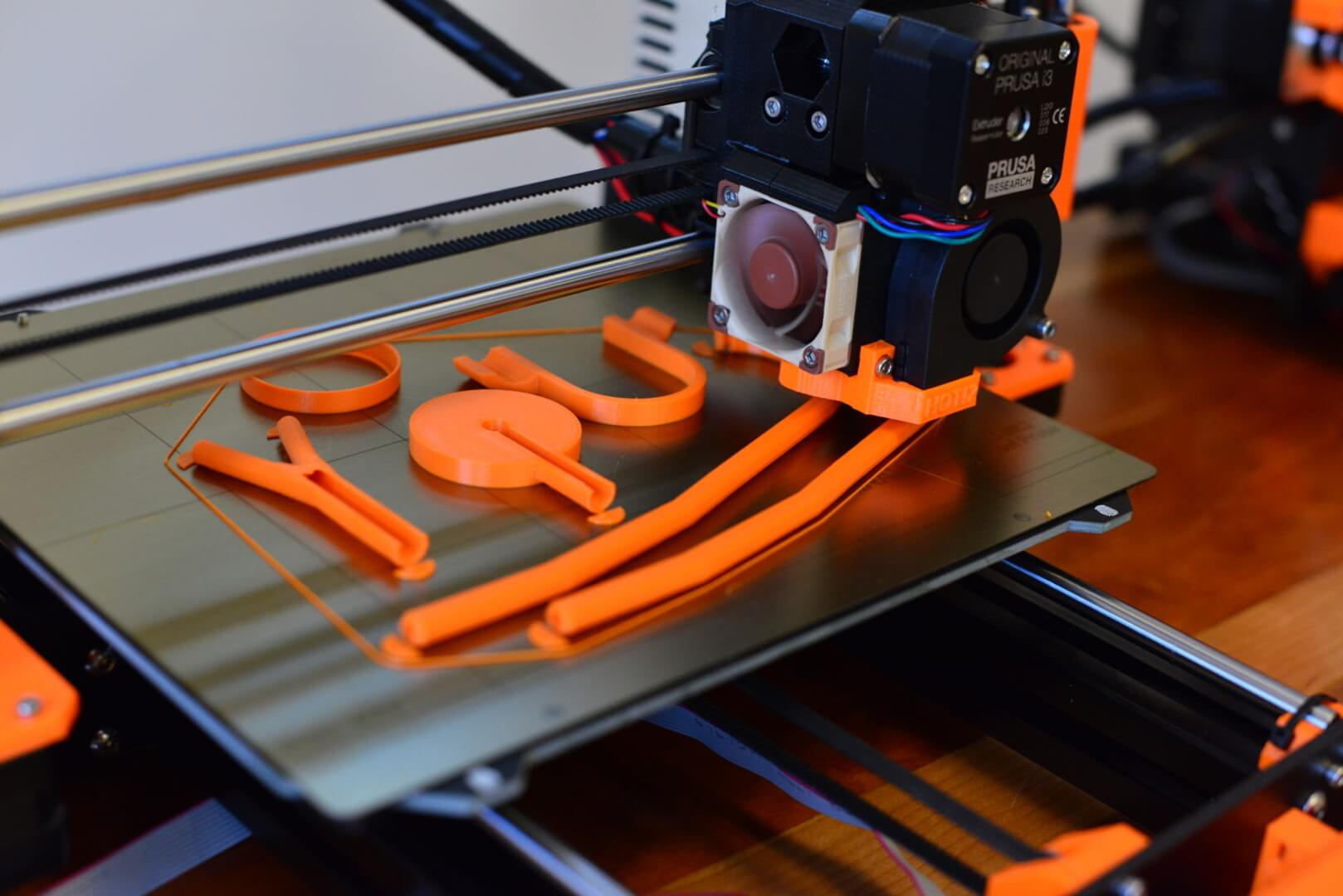

Father 3D Prints Orthoses for his Son, Now Helps Others

Reading Time: 3 minutesWhen Matej Vlašič was told that his son, Nik, who is afflicted with cerebral palsy, may never sit up, he began looking for a way to give him the best life possible regardless. With a little help from 3D printing and physical therapy, Nik cannot only sit up but also walk, cycle and…

-

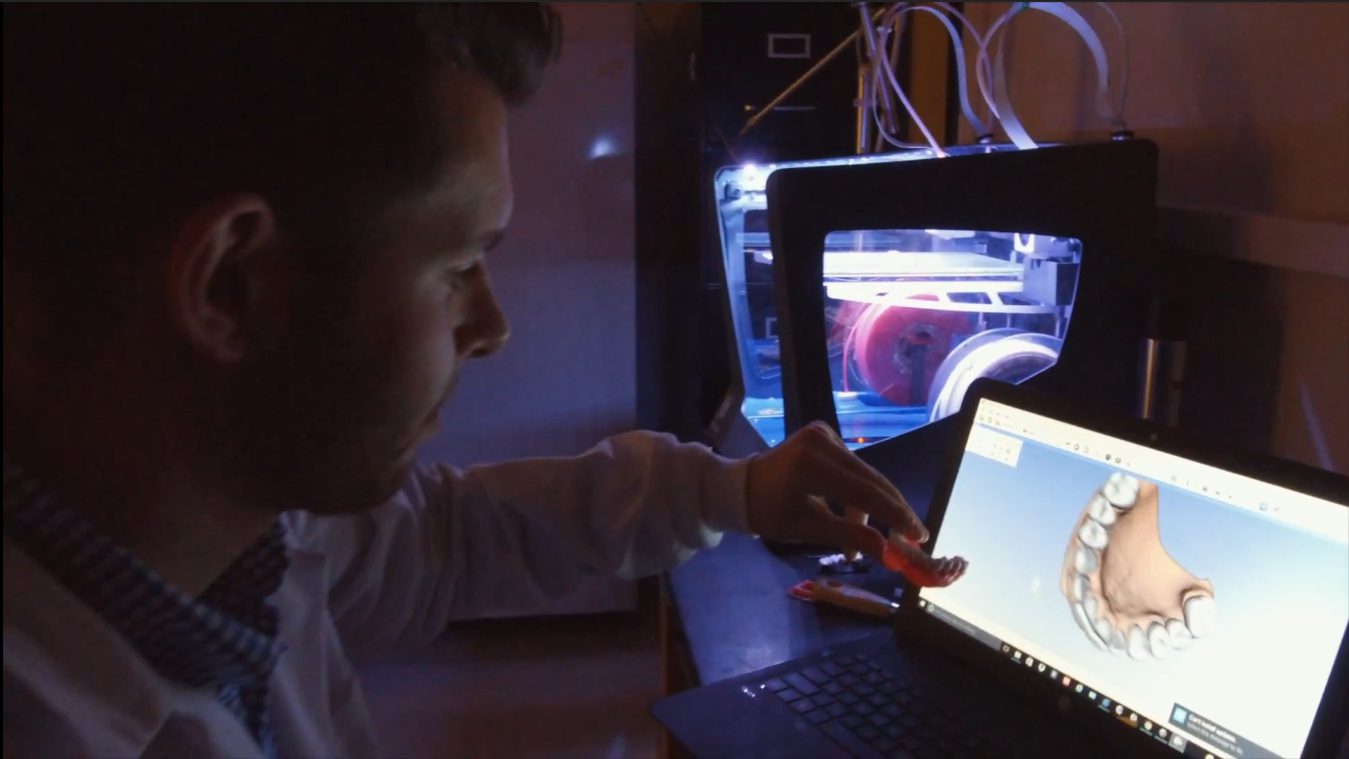

3D Printed Dentures Filled with Drugs to Fight Infection

Reading Time: 3 minutesResearchers at the University of Buffalo have invented 3D printed dentures which can be used to deliver drugs among those highly susceptible to infection, such as the elderly, hospitalized or disabled patients. For folks wearing dentures, an unfortunate side-effect can be fungal infections which cause inflammation, redness and swelling in the mouth.…

-

3D Printed Surgical Needle Inspired by Honey Bee Stingers

Reading Time: 3 minutesEngineers at Temple University in Philadelphia take inspiration from the insect kingdom for their 3D printed surgical needle design; the stinger of the humble honeybee. While exploring a new concept for a 3D printed surgical needle at Temple University in Philadelphia, Associate Professor of Mechanical Engineering Parsaoran Hutapea and PhD candidate Mohammad…

-

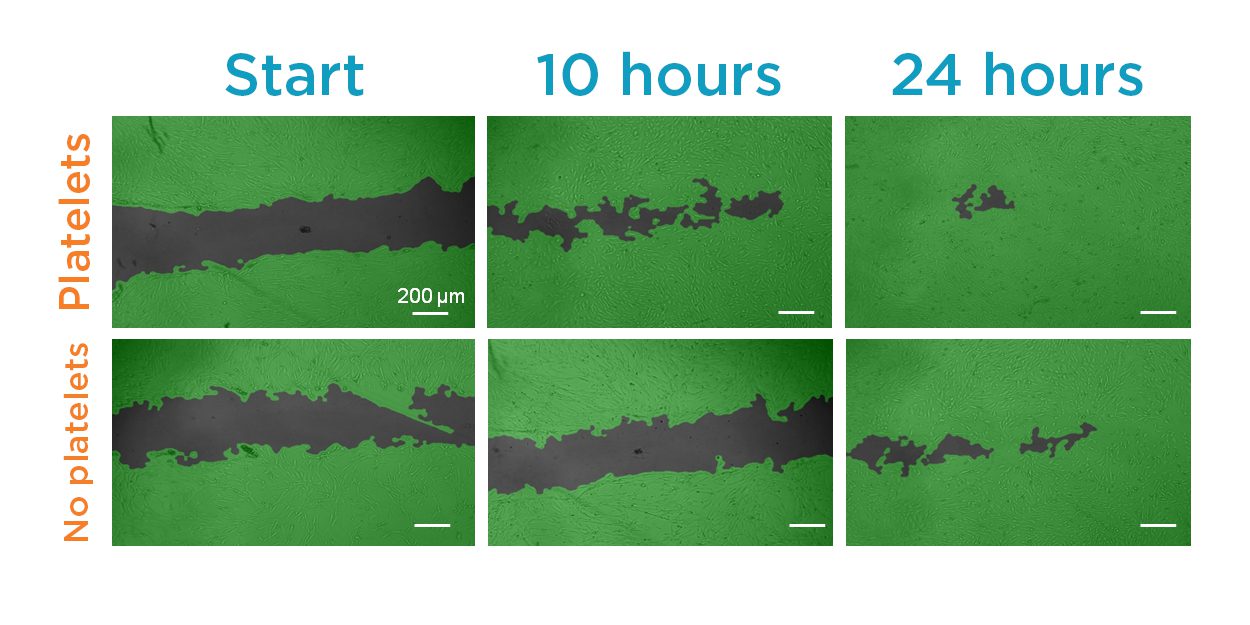

Printable Body Tissue with Personalized Bio-Inks Boost Healing Potential

Reading Time: 3 minutesBy embedding platelets into a 3D printed mixture of cells and gel, a team of researchers at the University of Nebraska-Lincoln hope to improve the healing properties of tissue implants and skin grafts with printable body tissue. Researchers from the University of Nebraska-Lincoln, MIT, and Massachusetts General Hospital have incorporated platelet-rich plasma…

-

Aether Launches Artificial Intelligence 3D Organ Printing Software

Reading Time: 3 minutesThe development could be a significant boost for on-site 3D organ printing at hospitals and research facilities. 3D organ printing has just been given a significant boost thanks an Artificial Intelligence (AI) powered medical imaging software developed by Aether. The new software powers automatic segmentation of organs and tissues. It further assists…

-

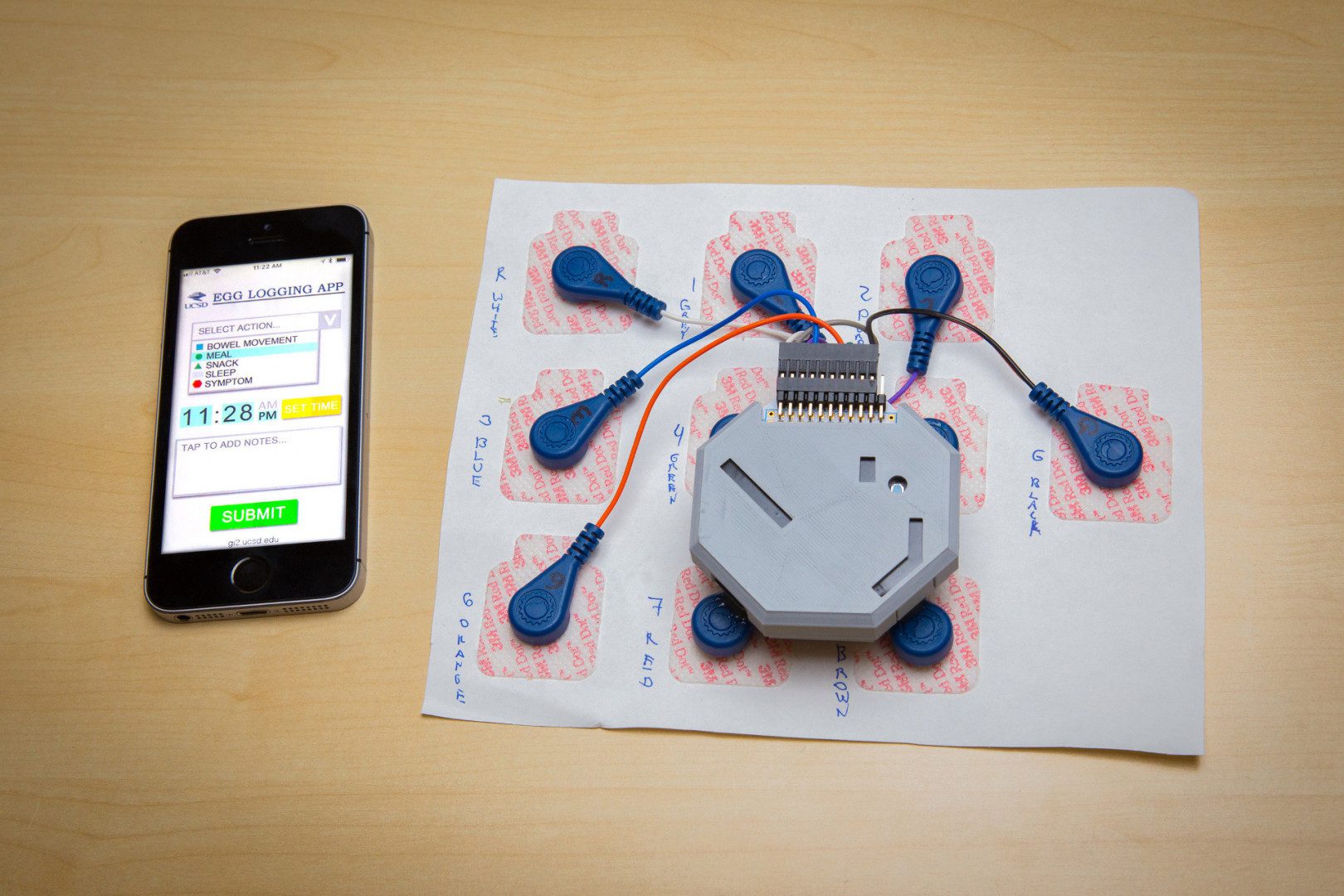

This 3D Printed Wearable Can Monitor Stomach Activity

Reading Time: 3 minutesScientists at UC San Diego create a 3D printed wearable to monitor stomach activity throughout the day, replacing the need for invasive probes. A team of engineers and physicians at the University of Sand Diego have developed a wearable, non-invasive system to monitor electrical activity in the stomach over 24 hours. Essentially,…

-

Getting to The Heart of the Matter with 3D Printing

Reading Time: 2 minutesCombining medically accurate models with allegorical artworks, new exhibition “The Heart of the Matter” takes a closer look at the complexity — and beauty — of the human heart using 3D printed sculptures. In literature and the arts, the human heart is frequently used to symbolize love and other emotions. But it…

-

Bandages that Stay on Your Joints Thanks to 3D Printing and Kirigami

Reading Time: 3 minutesResearchers from MIT are using 3D printing and an art form called kirigami to make plasters which actually stick to your elbows and knees. Everyone knows the irritation of hurting a joint, applying a plaster and it falling off just a few minutes later. If it’s not falling off, a plaster on…

-

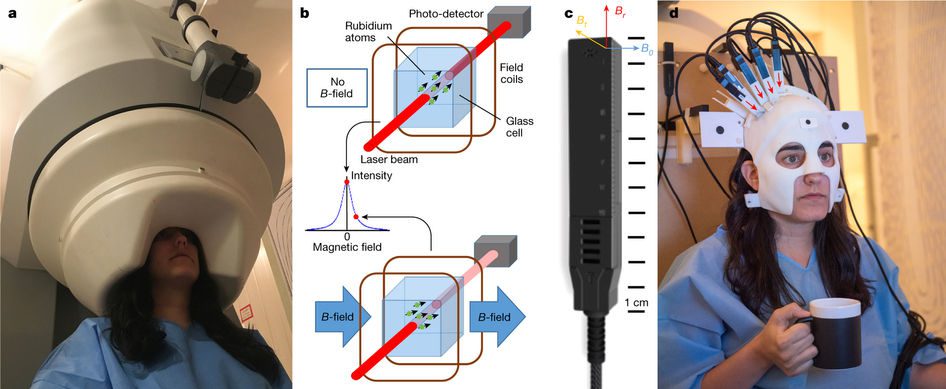

Play Ping Pong While Wearing a 3D Printed Brain Scanner?

Reading Time: 3 minutesResearchers from the UK developed a revolutionary 3D printed brain scanner which is effective even when a patient is moving — whether the movement is as simple as nodding their head or as active as playing ping-pong. Having your brain scanned is time-consuming and unpleasant to say the least. For them to…

-

This 3D Printed Stethoscope is Medical-Grade and Costs $3

Reading Time: 3 minutesDr. Tarek Loubani has designed a 3D printed stethoscope which can be made using recycled plastic in 3 hours for just $3. The device is especially useful in low-income countries which have little access to diagnostic tools. The stethoscope still has its place in medicine. Although many Western countries rely on CT scans…

-

Expectant Parents Can Now Get a 3D Printed Model of their Unborn Child

Reading Time: 3 minutesEmbryo 3D offers standard and metal-plated 3D printed models of fetuses crafted from ultrasound scans. Parents-to-be are now able to get their hands on a 3D printed model of their unborn child. Created by Embryo 3D, the process uses ultrasound scans to craft the plastic models of the fetus. Incredibly, the printing…

-

3D Bioprinting Models to Better Understand and Treat Neurodegenerative Diseases

Reading Time: 3 minutesScientists from Manchester, UK are using 3D bioprinting to investigate and better understand the brain’s neurovascular unit (NVU) which will hopefully lead to improved treatments for neurodegenerative diseases. Currently, there are no cures for neurodegenerative diseases such as Alzheimer’s, vascular dementia, Parkinson’s and stroke. However, scientists from the University of Manchester, UK are using…

-

Surgeons use 3D Printed Titanium Implant to Rebuilt Man’s Breastbone and Ribs

Reading Time: 2 minutesSurgeons in Wales used a 3D printed titanium implant to rebuild the chest of a 71-year-old man after a cancer removal operation which took three ribs and part of his breast bone. 3D printing has many medical uses, and for one of the first times in the UK, a titanium implant was…

-

Australian Sheepdog Receives Prosthetic Paw Thanks to 3D Printing

Reading Time: 3 minutesTucker, a five-year-old Australian sheepdog, can run on four feet again thanks to a 3D printed prosthetic paw. The hope is that the paw prosthetic will improve Tucker’s mobility and his quality of life. This is yet another story of how 3D printing can help animals. This time around, Tucker, a five-year-old Australian…

-

Scientists in India are Growing Ears in the Lab using Cartilage and a 3D Printed Scaffold

Reading Time: 3 minutesDoctors in Chennai, India are working on 3D printing transplantable ears. They’ve recently been successful in growing ear cartilage in a culture flask and proving it continues to grow once implanted in rabbits. For a couple of years, researchers from the SIMS Hospital and SRM University in Chennai, India, have been working on…

-

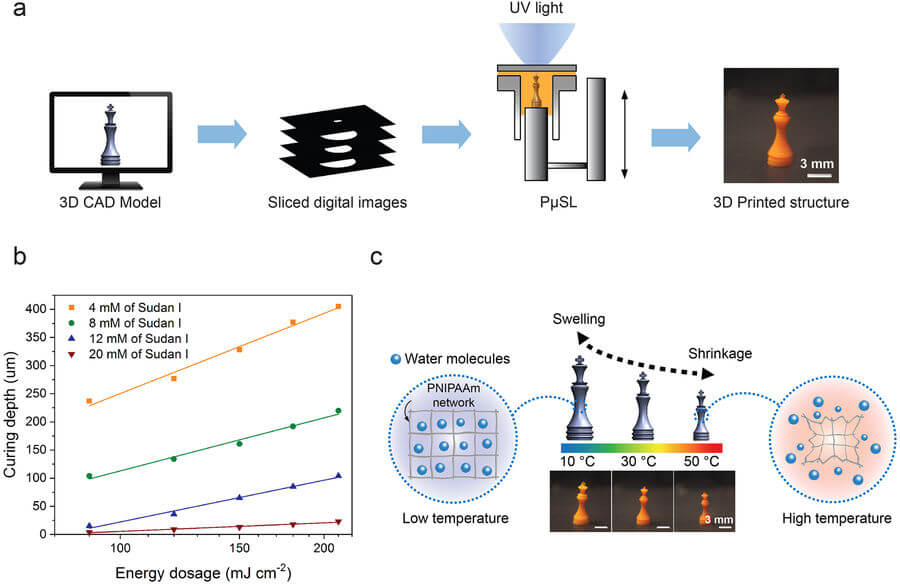

New 4D Printing Method May Revolutionize Tissue Engineering And Drug Delivery

Reading Time: 2 minutes3D printed object made from hydrogel shapeshifts after it has been printed. Engineers at Rutgers, the state university of New Jersey, and the New Jersey Institute of Technology have developed a 4D printing method which may find application in tissue engineering and targeted drug delivery systems. The 4D printing method uses a…

-

Boy Helps 3D Print Prosthetic Hands For Other Children

Reading Time: 3 minutesCameron Haight is unstoppable at helping other kids get the prosthetics they need. The five-year-old boy from North Carolina, US, has been making waves online for helping to 3D print prosthetic hands for himself and other kids. Cameron was born with amniotic band syndrome which has resulted in his digits being fused…

-

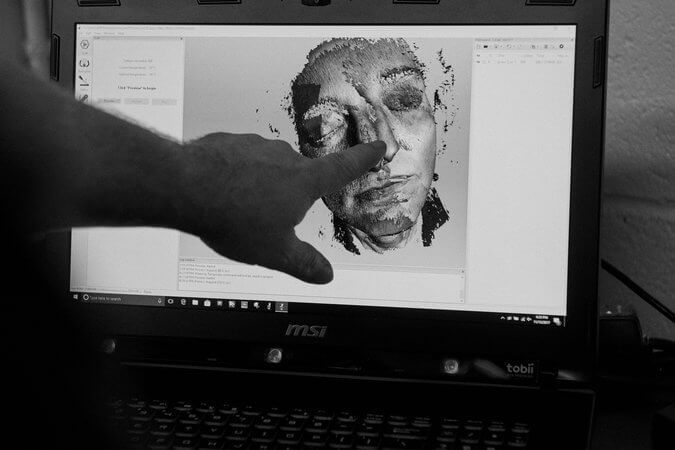

Face Donor to Get 3D Printed Mask for Burial

Reading Time: 3 minutesNew York University 3D printing specialists are to 3D print the face of a brain-dead man, before it is transplanted to a waiting recipient. It is thought the lifelike mask will bring dignity to funeral proceedings for the donor’s family. Plastic surgeons at New York University’s Langone Medical Center will perform an extraordinary surgery…

-

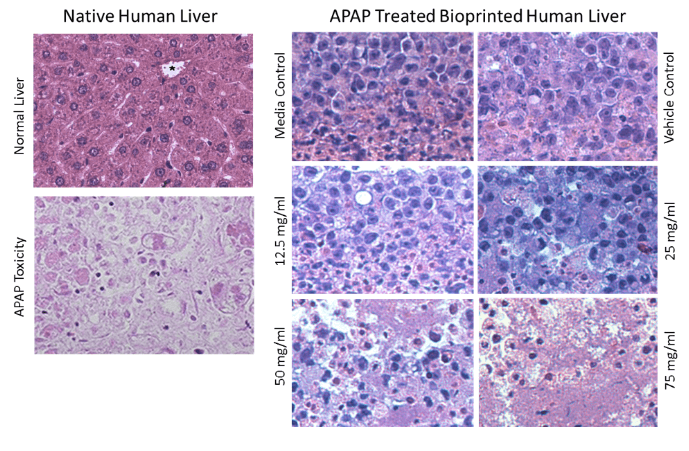

Organovo Gets Orphan Drug Designation for 3D Printed Liver Tissue

Reading Time: 2 minutesThe designation offers several benefits for Organovo, but more importantly, brings a potentially useful solution for alpha-1 antitrypsin deficiency to market. Organovo Holdings Ltd., the company that designs and creates 3D human tissues for drug discovery and clinical trials, has recently been granted orphan drug designation by the US Food and Drug…