Schlagwort: 3D printer filament

-

Industrial-Strength FDM Materials from BASF 3D Printing Solutions

Reading Time: 2 minutesA lot is happening for BASF 3D Printing Solutions, the subsidiary of the German chemical company developed last August which focuses on 3D printing. For example, it recently presented, at the Additive Manufacturing Users Group (AMUG) Conference in St Louis, a variety of new 3D printing materials. The subsidiary has been working…

-

![[DEAL] rigid.ink Flexible PLA 1kg 2.85mm, 25% Off at $38.79](data:image/svg+xml;charset=utf-8,%3Csvg xmlns%3D'http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg' viewBox%3D'0 0 1858 1044'%2F%3E)

[DEAL] rigid.ink Flexible PLA 1kg 2.85mm, 25% Off at $38.79

Reading Time: 2 minutesBritish filament maker rigid.ink is clearing its back-stock, slashing 25% off the price of some Flexible PLA. Designed to eliminate the frustrations of printing flexible filament by adding the ease of PLA, rigid.ink’s Flexible PLA sounds like a dream. Stiffer on the spool with a shade less elasticity than other flexibles, it…

-

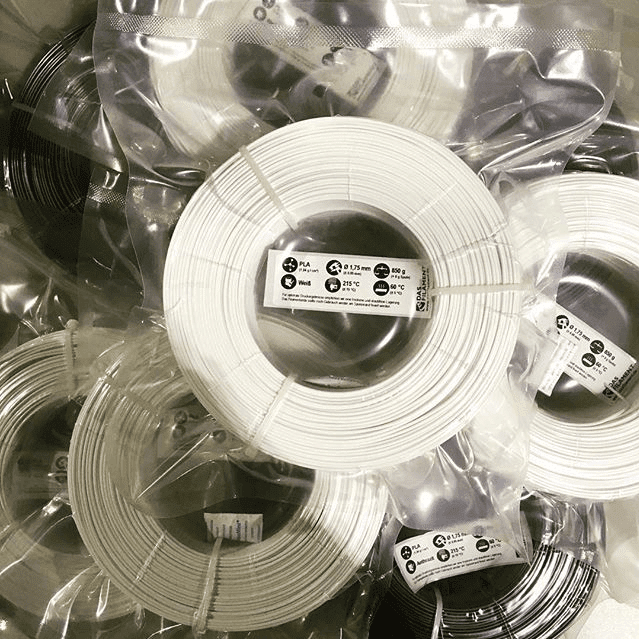

MasterSpool Could Help Reduce Waste When Buying 3D Printing Filament

Reading Time: 3 minutes3D printing expert Richard Horne (a.k.a. RichRap) is proposing a new way to receive filament which involves one MasterSpool and minimally packaged refills. Already manufacturers such as Das Filament are onboard with this idea. It’s not news to anyone that consumers are becoming more eco-conscious and demanding environmentally friendly products. As a result,…

-

6 Safe Ways How To Remove 3D Prints From The Bed

Reading Time: < 1 minuteThis method works more subtle than the previous ones. Especially heated beds form a seemingly indestructible bond with the printed material sometimes. So the first step after a print has finished is to let the printer and the heated bed cool down completely. If you’re lucky, the print pops right off…

![[DEAL] rigid.ink Flexible PLA 1kg 2.85mm, 25% Off at $38.79](https://www.blogdot.tv/wp-content/uploads/2018/02/deal-rigid-ink-flexible-pla-1kg-2-85mm-25-off-at-38-79.jpg)