Schlagwort: 3D printed prosthetic

-

Million Waves Project 3D Prints Prosthetic Limbs From Ocean Plastics

Reading Time: 3 minutesCharitable non-profit Million Waves Project combines a passion for cleaning up the ocean with helping young people in need: this young organization aims to provide prosthetic limbs 3D printed from reclaimed ocean plastics for children in need, worldwide, free of charge. Ocean plastic pollution is a core issue right now, with increasingly…

-

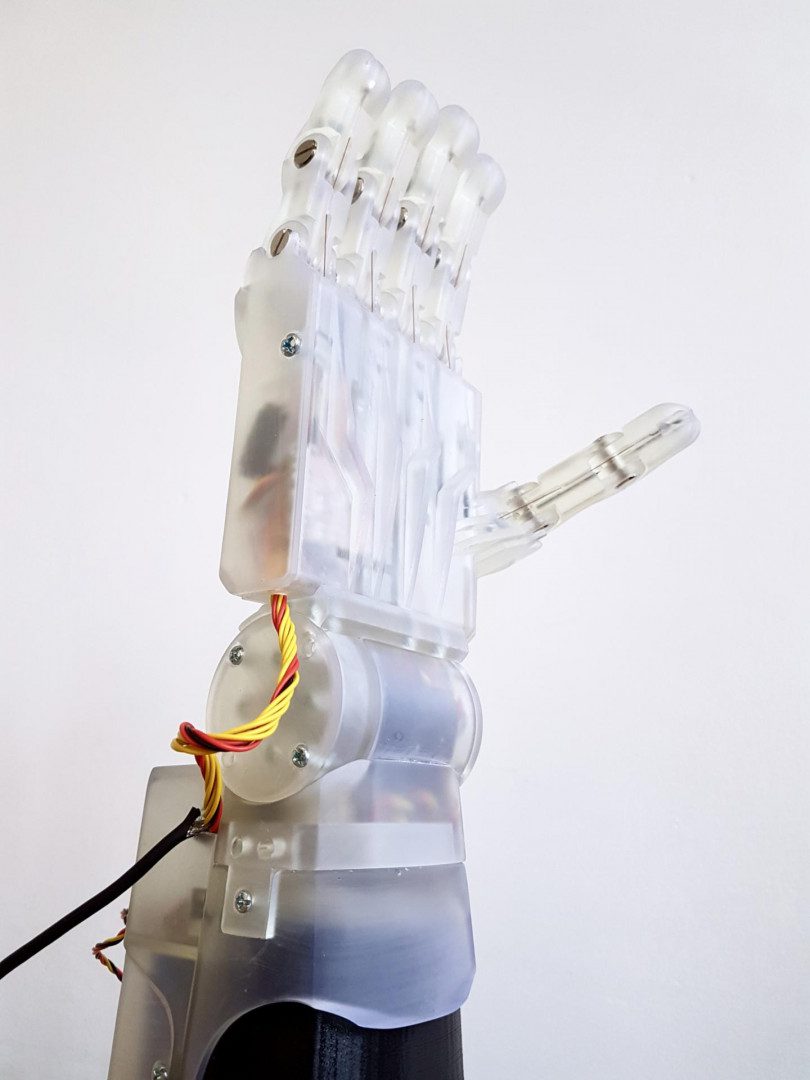

Researchers 3D Print Functional Robotic Prosthetic Hand at a Fraction of the Cost

Reading Time: 3 minutesResearchers from the University of Manchester have developed an extremely affordable 3D printed robotic prosthetic hand. The assistive device enables groundbreaking functionality for amputees, and can be fully customized for the user via an Android app. A team of designers from the University of Manchester have recently created a robotic hand prosthetic with…