Schlagwort: 3d printed

-

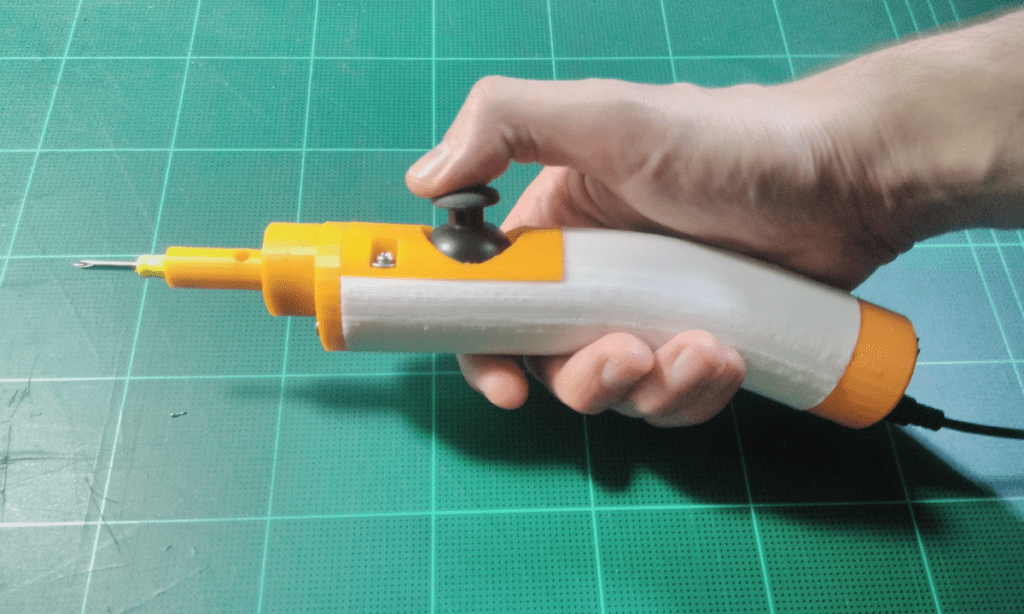

There’s no need to buy an electric screwdriver, just 3D print your own!

Reading Time: 2 minutesThere’s no need to buy an electric screwdriver, just 3D print your own! Arduino Team — December 11th, 2018 What do you do when you need to attach 400-500 screws for an upcoming project? If you’re “Progress Thailand” you simply create one yourself using a 9g micro servo modded for continuous rotation, an…

-

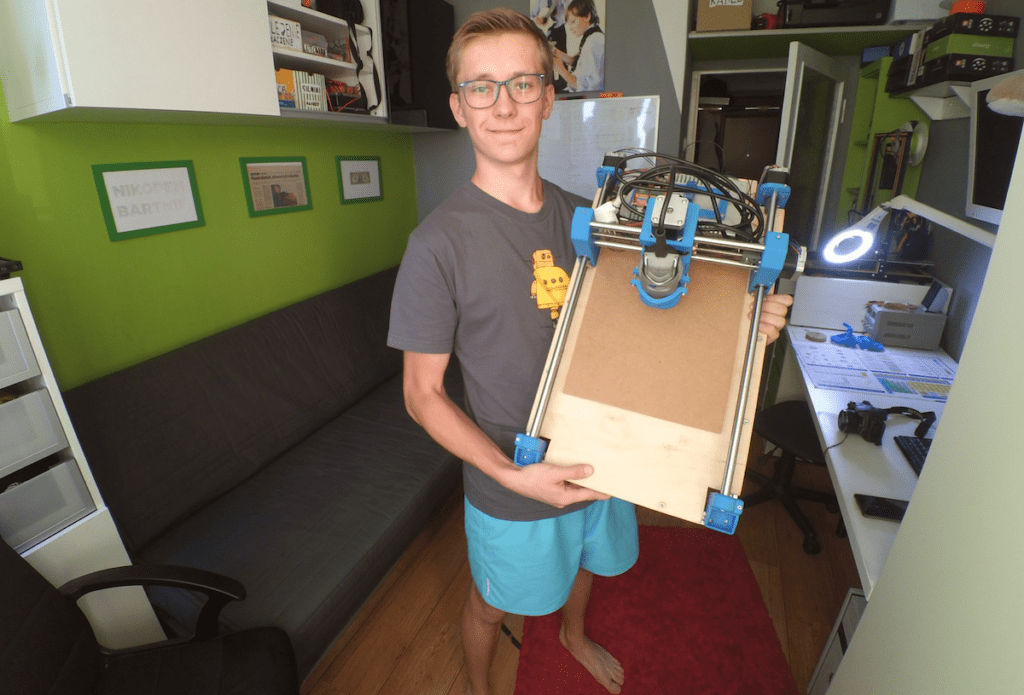

Convert a Dremel tool into an Arduino-controlled CNC machine

Reading Time: 2 minutesConvert a Dremel tool into an Arduino-controlled CNC machine Arduino Team — November 26th, 2018 3D printers get most of the attention in maker-fabrication news, but other computerized tools, like laser cutters and CNC routers, can also be extremely useful. In fact, Nikodem Bartnik decided to create his own Dremel-based machine constructed…

-

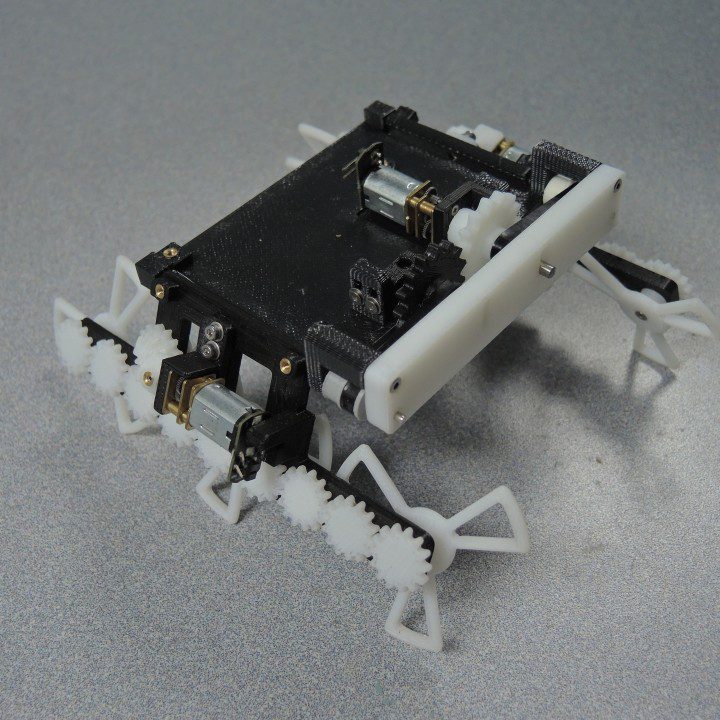

This 3D Printed Robot Can Crawl Underneath Doors

Reading Time: 2 minutesA designer has developed a 3D printed robot that can auto-adjust its height to maneuver a wide range of spaces. A Reddit member called potentprintables has just presented a 3D printed robot that adjusts its size in order to fit into tight spaces. That means the robot can also squeeze underneath doors.…

-

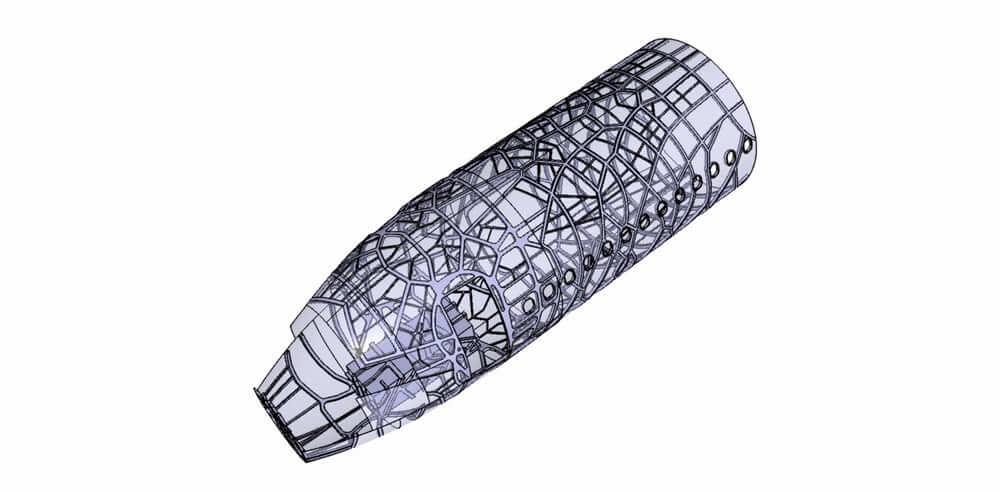

Stelia Aerospace Demos Cheap, Light and Strong Aircraft Fuselage Using WAAM

Reading Time: 3 minutesFrench firm Stelia Aerospace has lifted the lid on its newest innovation. Using WAAM (wire arc additive manufacturing), the company has demonstrated metallic self-reinforced aircraft fuselage panels that cut costs and save time from the assembly process. Aircraft structures and seating are the bread and butter of Stelia Aerospace’s business, with its designs and…