Schlagwort: 3d print

-

Wasp Launches 2 New Ceramic 3D Printers

Reading Time: 2 minutesThe Italian 3D printing manufacturer tested its new range of ceramic 3D printers on a remake of Michelangelo’s famous David sculpture. WASP, the 3D printer manufacturer, has just presented a new product line that allows for the 3D printing of clay and other dense semi-fluid materials. The company officially launched the DeltaWASP…

-

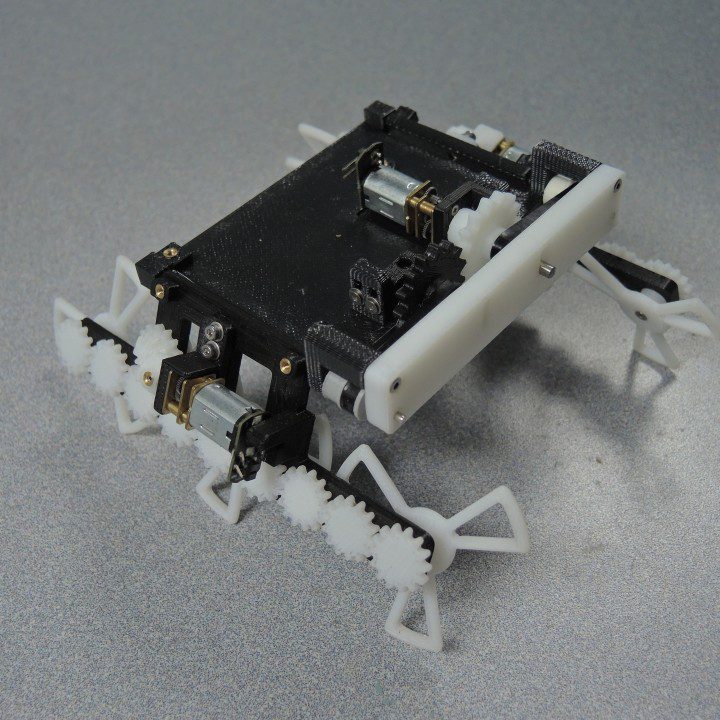

This 3D Printed Robot Can Crawl Underneath Doors

Reading Time: 2 minutesA designer has developed a 3D printed robot that can auto-adjust its height to maneuver a wide range of spaces. A Reddit member called potentprintables has just presented a 3D printed robot that adjusts its size in order to fit into tight spaces. That means the robot can also squeeze underneath doors.…

-

Proterra Partners With Carbon to 3D Print Emission-Friendly Bus Fleet

Reading Time: 3 minutesBy working with 3D printing technologies, Proterra has been able to save costs and speed up the production of its zero-emission battery-powered buses. Proterra is looking to speed up its zero-emission bus mission by working with 3D printed parts. The Silicon Valley start-up focuses on solving public transport by developing electric buses…

-

ThingMaker is a 3D Printer for Kids

Reading Time: < 1 minute[mbYTPlayer url=“https://www.youtube.com/watch?v=mw8w7cTKEHI“ opacity=“.5″ quality=“medium“ ratio=“auto“ isinline=“false“ showcontrols=“false“ realfullscreen=“true“ printurl=“true“ autoplay=“true“ mute=“true“ loop=“true“ addraster=“true“ stopmovieonblur=“false“ gaTrack=“false“] We try out ThingMaker from Mattel, their new Autodesk partnered 3D printing toy/product for children.

-

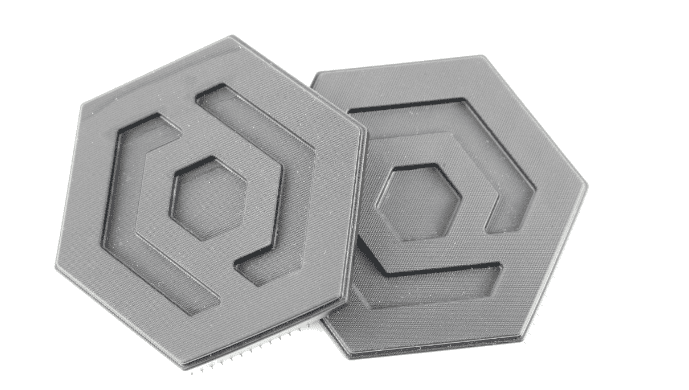

3D Printed 5,000$ Walking Robot Tank – Timelapse VIDEO

Reading Time: < 1 minuteThe HMS Boudicca, by Singapore toy maker Michael Sng, isn’t just a static sculpture, it’s a fully-functional, 3D-printed robot tank. That’s right, it was painted and assembled entirely by hand, boasting a hexapodal walking motion, powered toy guns, along with a host of other electronics. Believe it or not, you can…