Schlagwort: 3d bioprinting

-

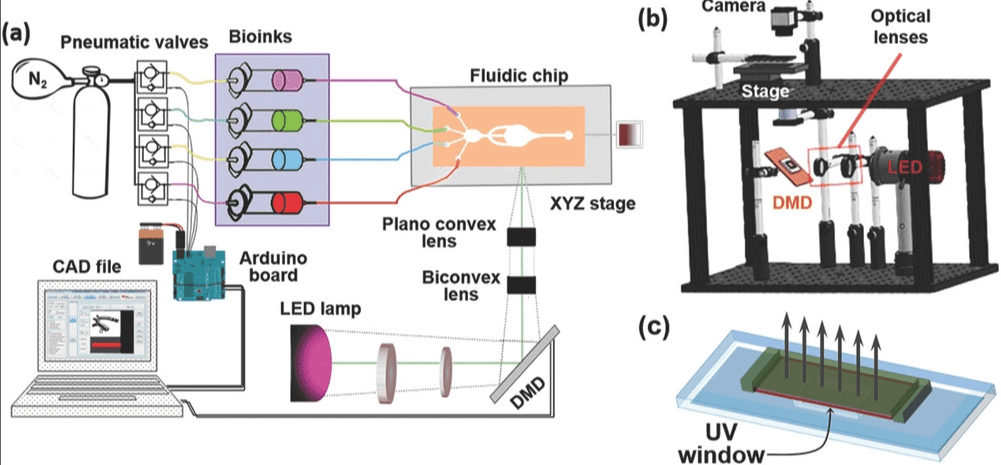

UCLA Bioengineer Develops SLA 3D Printer That Produces Complex Artificial Tissues

Reading Time: 3 minutesResearchers from UCLA have developed a SLA-based bioprinter that is able to create therapeutic biomaterials from multiple materials. This advancement could potentially be used for on-demand printing of complex artificial tissues for use in transplants and other surgeries. Body tissues are highly complex and made of various different cell types, and this makes…

-

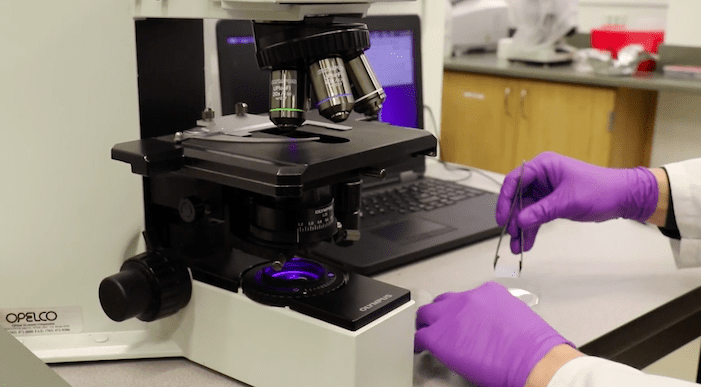

Nano-3D Printing Technology Helps Develop Improved Biochips

Reading Time: 2 minutesThe nanoprinting method enables printing of multiple molecules without damaging existing molecule layers – a perfect match if you want to fabricate delicate biochips. Researchers at the City University of New York’s Advanced Science Research Center (ASRC) and Hunter College have come up with a novel solution to print biochips. They are using…

-

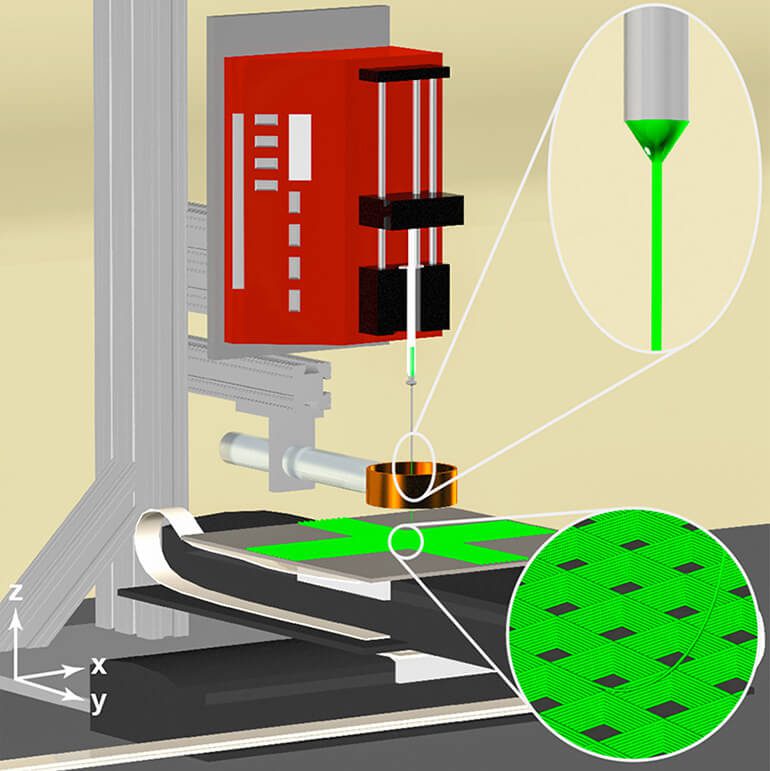

3D Jet Writing Technique Provides Better Understanding of How Cancer Spreads

Reading Time: 3 minutesResearchers from Purdue University and University of Michigan have developed a new 3D jet writer that allows them to print high-resolution polymer as microtissues. These tiny tissue structures are able to facilitate cancer cell growth, allowing for improved drug development and testing. A team of researchers at Purdue University and University of Michigan…

-

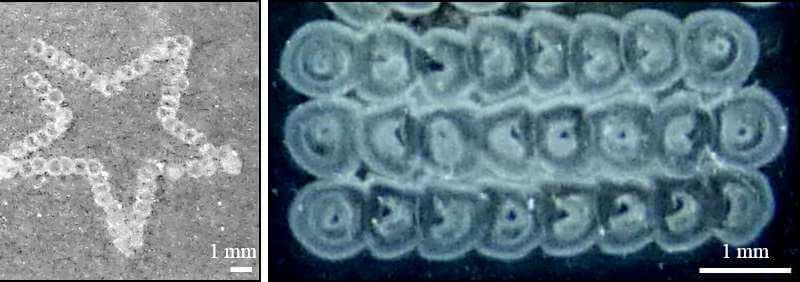

Researchers Develop Bioprinting Method to Recreate Biological Structures From Cells and Molecules

Reading Time: 3 minutesResearchers from Queen Mary University of London have developed a 3D bioprinting method that enables the creation of biological structures from cells and molecules that are commonly found in natural tissues. From human skin to ears made from a patient’s own cells, 3D bioprinting has changed the landscape of medical innovation in…

-

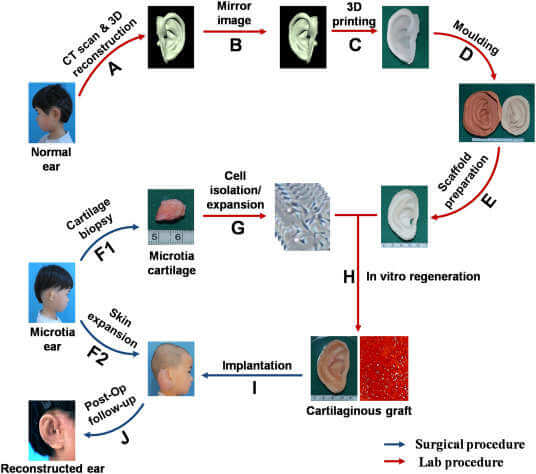

Researchers 3D Bioprint the First Ears Made From Childen’s Own Cells

Reading Time: 3 minutesA team of Chinese plastic surgeons and tissue engineers have devised a method to 3D print cells which assemble into a replica of a patient’s ear. Five children suffering from unilateral microtia in China are the first patients to receive newly grafted ears made from their own cells. Tissue engineers made the…