Researchers at Purdue University have developed a technique to safely and precisely deposit tiny traces of highly reactive materials.

Ever wonder how airbags deploy so quickly? The answer is a small amount of solid propellant, which is ignited to achieve a tiny burst. And that’s just one example of micromechanical systems benefiting from energetic material.

Taking the technology one step further is a diverse team of researchers from Purdue University in Indiana. They’ve developed a means to deposit tiny amounts of energetic material with unprecedented levels of precision and safety.

Essentially, energetic materials are solids that rapidly produce large amounts of thermodynamic energy when ignited. Examples include explosives, propellants, and pyrotechnics.

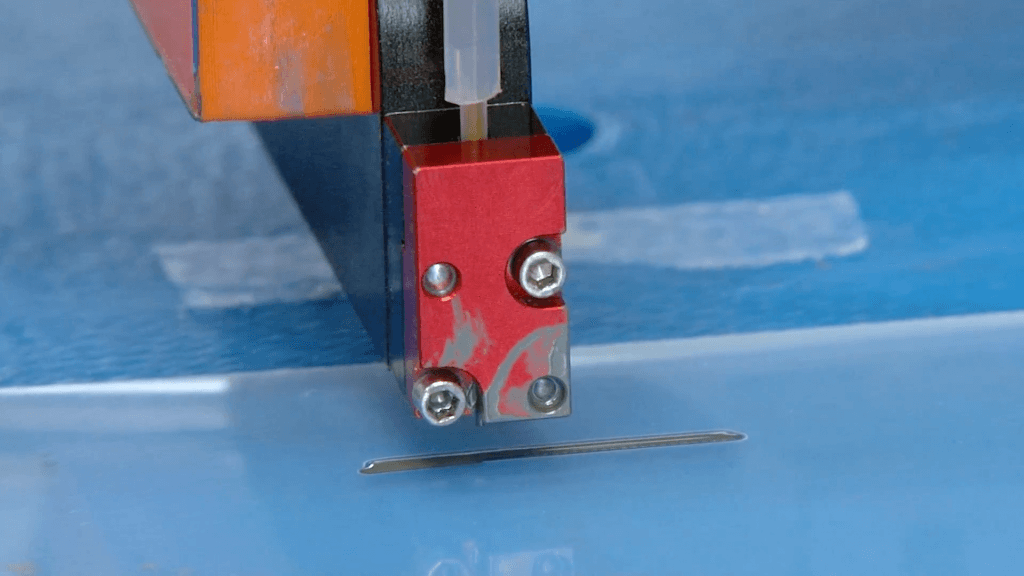

The team’s printing method combines expertise in this area with knowledge of additive manufacturing. Apart from the “extruder”, which uses inkjet technology, their custom machine uses normal principles of deposition printing to weave two materials with a high degree of complexity.

In order to produce the desired explosive effect, a metal and metal-oxide must overlap in such a way as to permit in situ mixing. Thanks to the team’s efforts, these materials — called nanothermites — can now be deposited at a precision of 0.1 microns. That’s 1000 times thinner than a human hair!

A Complex Technology with a Complex Team

Instead of an extruder with a hot-end, the researchers’ printer uses inkjet technology. Specifically, a glass tube is surrounded by material that flexes when voltage is passed through it, squeezing the glass tube in order to force droplets out of the nozzle.

By adjusting the voltage, the size of the drops and their rate of propulsion can be finely tuned.

This type of inkjet printing is called piezolectric. It has the advantage over other methods of allowing for a wider range of printing materials. Of course, explosives probably weren’t on anyone’s minds when inkjet printing was first being developed, back in the 70s.

Even the team at Purdue is able to experiment with different types and amounts of energetic material. Some burn hotter than 3000 degrees Celcius, and droplet volumes are in the range of picoliters (10−12).

Managing all the various factors requires a diverse group of experts. The printer’s creator is Allison Murray, a Ph.D. candidate in mechanical engineering. She’s supervised by four professors. Dr. Rhoads is a professor in the same field, but Dr. Chiu is an expert in inkjet printing and Drs. Gunduz and Son in energetic material.

It’s thanks to this unique collaborative environment at Purdue that this research, which has huge potential, has come to exist. Murray reflects on her own experience:

“When you think engineering, you’re thinking maybe the automotive industry… maybe I’ll make a plane… And then this project comes across your radar, of energetic material and additive manufacturing, which are two things that I personally never saw together. But now that I have, I’ve been able to gain a lot of knowledge in both areas.”

Source: Purdue University

Website: LINK

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.