Engineers from Northwestern University have developed a new method to 3D print powerful lenses in a rapid manner. These lenses could be used to turn your iPhone into a microscope for high quality photos or on-the-spot disease diagnosis.

Researchers from Northwestern University have recently developed a groundbreaking method to produced powerful 3D printed lenses. The team of engineers have spent two years devising the technique, and can now 3D print a high-quality customized lens in just four hours time. The lenses are extremely tiny, measuring just 5mm high and 5mm wide.

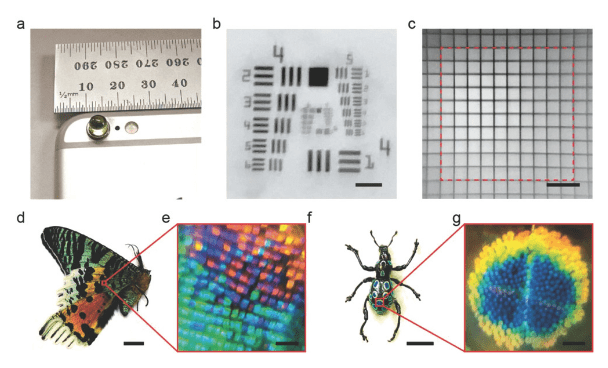

These lenses could be used for a vast array of optical applications, such as creating personalized contact lenses to correct poor vision. They could also be used to transform your iPhone into a microscope, allowing you to take detailed images or make on-the-spot disease diagnosis. To prove the concept, the researchers used the 3D printed lenses to photograph intricate things like sunset moth’s wing and a spot on a weevil’s elyta (pictured below).

Moreover, the 3D printed lens production technique could offer significant benefits for faster medical diagnosis, especially in remote areas that are hard to reach or where medical equipment is sparse.

“Up until now, we relied heavily on the time-consuming and costly process of polishing lenses. With 3D printing, now you have the freedom to design and customize a lens quickly,” said Cheng Sun, associate professor of mechanical engineering at Northwestern University.

Northwestern Researchers Develop 3D Printed Lenses with Clear Optics

The 3D printing process developed at Northwestern involves layering the lens material one layer at a time. During the initial trials, this led to an unwanted stepping effect in the curvature of the layer, which ended up distorting the image. And so, the team of engineers set out to improve their concept.

“We realized that the layers on top of each other created surface roughness. The layer thickness is typically 5 microns, while the wavelength of visible light is around 0.5 micron. This creates an optically rough surface,” adds Sun. “That was the bottleneck. The roughness made the lens incapable of clear optics.”

This issue led the team to develop a technique that would create a smoother surface. This required using a slower 3D printing speed, as well as additional transitional steps. The team ended up using grayscale images to add transitions between steps and then coated the surface with photo-curable resin material.

A similar 3D printed lens has been developed in the past by the German nanotechnology company Nanoscribe. The company uses a high-precision femto-second 3D printer with 150 nanometer precision, but instead of layering, it builds lenses in a point-by-point fashion. According to the Northwestern researchers, Nanoscribe’s 3D printing process takes much longer compared to their own method.

In the near future, the researchers are planning to experiment with creating larger lenses. They also plan to test out how 3D printed lenses can be used with various medical devices, such as an endoscope or optical microscope.

Their research paper, entitled “High-Speed 3D Printing of Millimeter-Size Customized Aspheric Imaging Lenses with Sub 7 nm Surface Roughness”, was recently published in Advanced Materials.

Source: Science Daily

Website: LINK

Schreibe einen Kommentar

Du musst angemeldet sein, um einen Kommentar abzugeben.